Spherical cerium oxide porous abrasive and its use in ultra-precision polishing

A cerium oxide, ultra-precise technology, applied to polishing compositions containing abrasives, inorganic chemistry, grinding devices, etc., can solve the complex synthesis process of porous abrasives, difficult to control the morphology and structure of the final product of porous abrasive particles, etc., Achieve the effect of regular shape, low cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

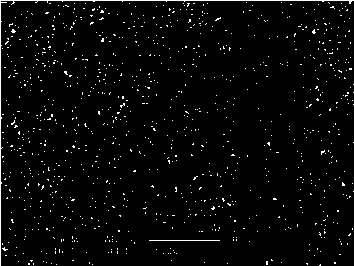

[0029] First place the micrococci in the culture medium (the formula is 200 mL of distilled water, 1 g of glucose, 0.5 g of sodium chloride, 1 g of fish meal peptone, 4 g of agar and 0.5 g of yeast extract), and then place the petri dish at a constant temperature. Bacteria were cultured in a humid chamber at a temperature of 24°C and a relative humidity of 40%. After 4 days of culture, coccus templates with a size of 100 nm to 200 nm can be obtained.

[0030]Weigh 1 g of the coccus template obtained by the above conditional culture and place it in a beaker, add 95 mL of distilled water and 5 mL of absolute ethanol in sequence, then add hydrochloric acid dropwise to adjust the pH value of the system to 3, and stir evenly with a magnetic stirrer. Then 2.52 g of cerium nitrate was added to adjust the concentration of cerium ions to 0.02 mol / L, fully stirred evenly under the condition of magnetic stirring, and then immersed for 66 h; Slowly dry in a blast drying oven at 40°C; fir...

Embodiment 2

[0035] The steps of this example are basically the same as those of Example 1 above, except that the concentration of cerium ions in the solution system is 0.01 mol / L, and the immersion time is 70 hours; after the full immersion, the coccus template is centrifuged and placed at 20 ° C under air blast Dry slowly in a drying oven, and then calcinate the impregnated and dried cocci template under nitrogen protection at 400 °C for 1 h; then place the pre-calcined product in a muffle furnace, Secondary calcination was carried out at 300 °C for 1 h.

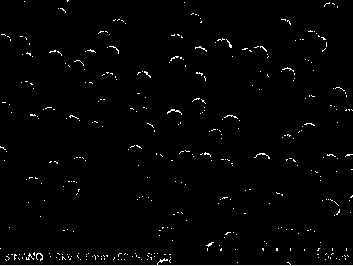

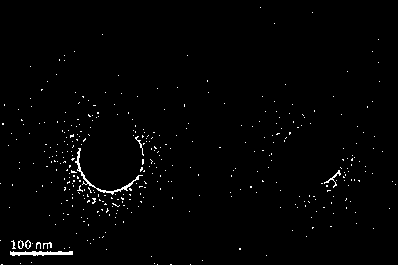

[0036] Scanning electron micrographs and transmission electron micrographs of the porous cerium oxide abrasive sample prepared in Example 2, nitrogen adsorption and desorption curves are similar to those in Example 1, and its specific surface area is about 48.6 m 2 / g, the pore volume is about 0.31 cm 3 / g, which is significantly higher than that of traditional cerium oxide solid particles (16.3 m 2 / g, 0.08 cm 3 / g).

[0037] ...

Embodiment 3

[0040] The procedure of this example is basically the same as that of Example 1 above, except that the concentration of cerium ions in the solution is 0.5 mol / L, soaked for 48 hours, centrifuged to separate the coccus template after fully soaked, and placed in a blast drying oven at 50 °C Dry slowly, and then calcinate the impregnated and dried cocci template at 600 °C under nitrogen protection, and keep it warm for 3 h; then place the pre-calcined product in a muffle furnace, Carry out secondary calcination and keep warm for 3 h.

[0041] Scanning electron micrographs and transmission electron micrographs of the porous cerium oxide abrasive sample prepared in Example 3, nitrogen adsorption and desorption curves are similar to those in Example 1, and the specific surface area is about 51.2 m 2 / g, the pore volume is about 0.34 cm 3 / g, which is significantly higher than that of traditional cerium oxide solid particles (16.3 m 2 / g, 0.08 cm 3 / g).

[0042] The porous ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com