Antiviral and antibiotic fiber, and preparation method and use thereof

An antibacterial fiber and anti-virus technology, applied in the fiber field, can solve the problems of poor affinity and hinder fiber graft polymerization reaction modification, etc., and achieve the effects of energy saving, rich raw materials and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

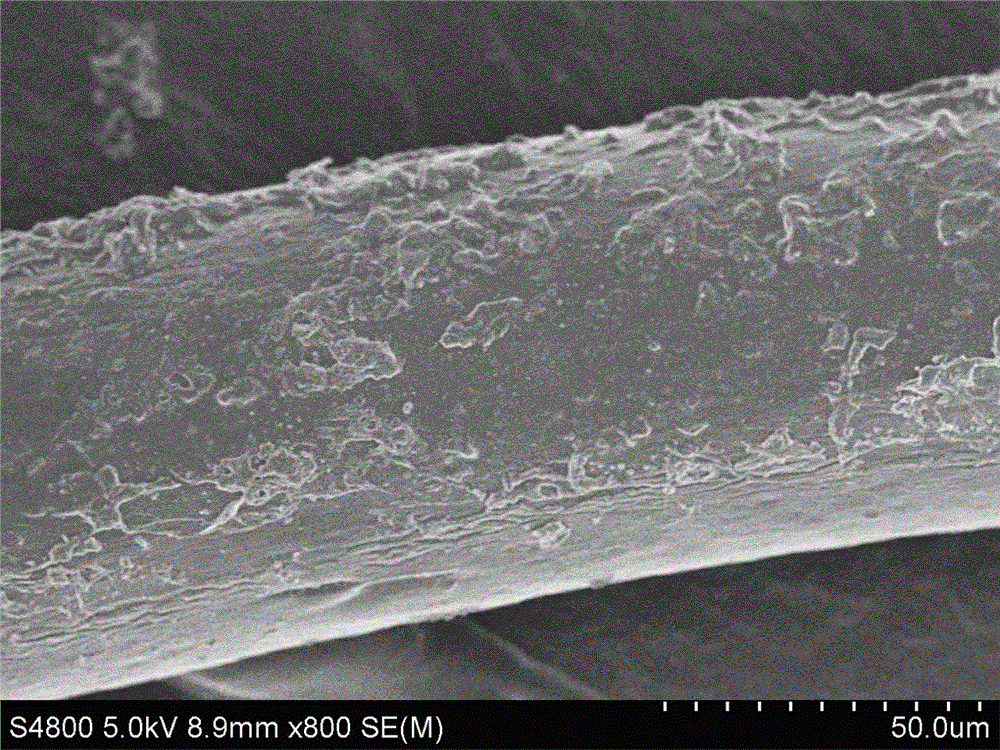

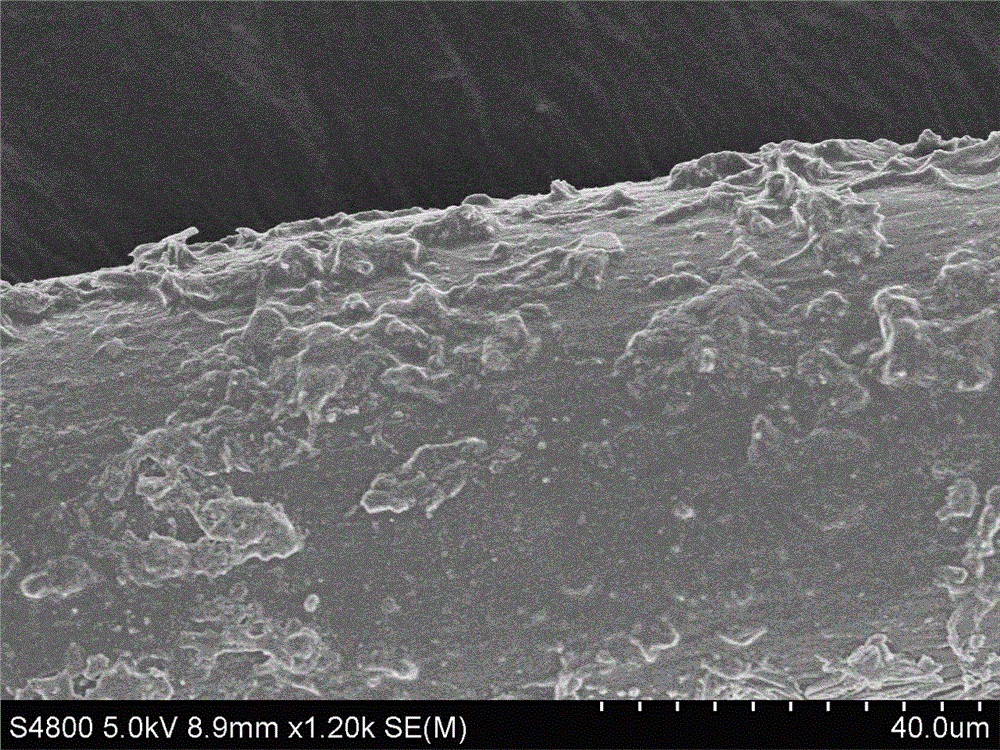

Image

Examples

Embodiment 1

[0027] Get 20g polypropylene fiber, after irradiation dosage is the gamma ray pre-irradiation of 40kGy, be placed in 200ml containing the olefinic monomer (being the acrylic acid of 2wt%, 2wt% methacrylamide, 1wt% acrylamide), 0.01wt% ammonium ferrous sulfate, and water as the balance, and reacted at 80°C for 1 hour to obtain pretreated polypropylene fibers. The solution can be reused after treatment.

[0028] The above-mentioned 20g polypropylene fiber after pretreatment is placed in 120ml of monomers containing cationic functional groups (i.e. 4wt% benzylethyltrimethylammonium chloride (CAS No. 26616) containing 5wt% by weight of the total solution -35-3), 1wt% of diallyl dimethyl ammonium chloride), 1wt% of polyquaternium salt (that is, 1wt% of polydimethyldiallyl ammonium chloride), 0.01wt% of Azobisisobutyronitrile, 0.01wt% triethylamine, 25wt% acetone, and a solvent with the balance being water, reacted for 30min under the ultraviolet light of a high-pressure mercury va...

Embodiment 2

[0030] Take 20g of viscose fiber, place it in 500ml solution containing 5wt% alkaline solution based on the total solution weight (that is, 5wt% sodium hydroxide), and the balance is water, soak at 80°C for 30min, and obtain alkali-treated Viscose. Put the viscose fiber after the alkali treatment in 150ml containing 40wt% olefinic monomers containing hydrophilic groups based on the total solution weight (i.e. 10wt% acrylic acid, 30wt% hydroxyethyl methacrylate), 0.5 In a solution of wt% benzophenone, 0.5wt% triethylamine, 20wt% ethanol, and the balance being water, react under the ultraviolet light of a high-pressure mercury vapor lamp with a power of 300W and a light intensity of 90% for 10 minutes , to obtain the pretreated viscose fiber.

[0031] Put the above-mentioned 20g viscose fiber after pretreatment into 100ml of monomers containing 15wt% cationic functional groups based on the total solution weight (i.e. 5wt% acryloyloxyethyltrimethylammonium chloride, 10wt% % dia...

Embodiment 3

[0033] Take 20g of polyacrylonitrile non-woven fabric to undergo graft polymerization reaction with olefin monomer solution containing hydrophilic groups through ultraviolet light irradiation, wherein the ultraviolet light irradiation conditions are: a high-pressure mercury vapor lamp with a power of 150W and a light intensity of 100%. react under UV light for 50 min. A pretreated polyacrylonitrile nonwoven fabric is obtained. Then place 200ml of olefinic monomers containing 5wt% hydrophilic groups based on the total solution weight (i.e. 2wt% acrylic acid, 2wt% methacrylamide, 1wt% acrylic acid amide), 0.01wt% In a solution of ferrous ammonium sulfate and water as the balance, react at 80° C. for 1 hour to obtain a pretreated polyacrylonitrile nonwoven fabric.

[0034] Put the above-mentioned 20g polyacrylonitrile non-woven fabric after pretreatment into 100ml of monomers containing 35wt% cationic functional groups based on the total solution weight (i.e. 35wt% acryloyloxyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com