Method for preparing phosphatidylserine under catalysis of immobilized phospholipase D

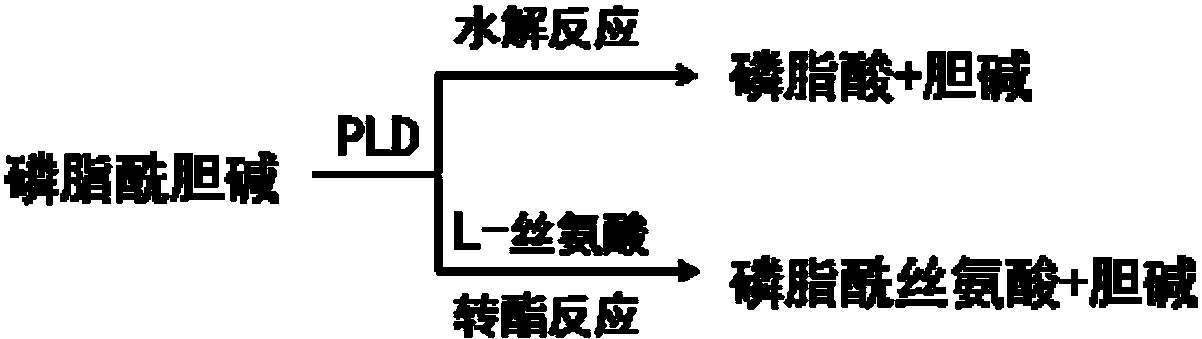

A technology of phosphatidylserine and immobilized phospholipase, which is applied in the field of immobilized phospholipase D to catalyze the preparation of phosphatidylserine, can solve the problems of weak physical adsorption force, easy inactivation of enzyme molecules, and harsh cross-linking conditions, etc. Effects of temperature and pH stability and resistance to organic solvents, method simplicity, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of free phospholipase D.

[0035] (1) Seed culture: Take a Streptomyces racemochromogenes ATCC23954 glycerol bacterium stored at -80°C, put it into a 250mL Erlenmeyer shaker flask (containing 100mL seed medium) at the inoculation amount of 1v / v% under sterile conditions, and put it into the shaker After bed, culture at 30°C, 200rpm for 48h.

[0036] (2) Fermentation culture: the above-mentioned seed culture solution is inserted in the fermenter by 2v / v% inoculum, the initial fermentation medium is 5L fermentation medium, the pH of the fermentation liquid is controlled to be 7.0 with 25wt% ammonia water, and oxygen aeration is regulated The volume was 1VVM, the temperature was controlled at 30°C, and cultured at 500rpm for 24h.

[0037] (3) Treatment of crude enzyme liquid: vacuum filter the fermentation liquid filter paper to remove agglomerated bacteria in the fermentation liquid, collect the supernatant, which is the fermented crude enzyme liqu...

Embodiment 2

[0040] Example 2: Preparation of immobilized phospholipase D.

[0041](1) Take 1g of chitin as a carrier, add 5ml of glutaraldehyde solution of cross-linking reagent at a concentration of 3v / v% (the solvent in the glutaraldehyde solution is 50mM sodium acetate buffer solution with pH 5.5), soak at room temperature And stir for 4 hours, let it stand overnight, centrifuge to remove the supernatant; wash the carrier repeatedly with distilled water to remove residual glutaraldehyde, and filter with suction to obtain the cross-linked chitin carrier, which is stored at 4°C;

[0042] (2) Take out 1g of cross-linked chitin carrier, add 5ml of free phospholipase D enzyme solution (total enzyme activity is 26.5U), then add 5mL of 50mM, pH5.5 sodium acetate buffer solution, put it in a shaker, Under the conditions of a constant temperature of 30°C and a shaker speed of 200rpm, after adsorption and cross-linking for 6 hours, take out and filter, wash with sodium acetate buffer (50mM, pH5....

Embodiment 3

[0044] Example 3: Application of immobilized phospholipase D to catalyze the preparation of phosphatidylserine from soybean lecithin in a biphasic system.

[0045] Take one 50mL centrifuge tube, add 2.0mL butyl acetate (containing 40μmol soybean lecithin PC), 2.0mL pH5.550mM sodium acetate buffer (containing 10mM CaCl 2 , 1M L-serine and 0.96 U of the immobilized phospholipase D) prepared in Example 2 were placed in a constant temperature shaker at 30° C. and 200 rpm for reaction. The reaction time was 5 hours, and the concentration of substrate and product was detected by HPLC. The transesterification rate was 92%.

[0046] Filter out the immobilized phospholipase D in the reaction system, wash it, and add new trace buffer, L-serine, and butyl acetate containing 20mM PC to catalyze it. It is found that it can be recycled five times in the biphase and still maintain The transesterification rate is about 83% (mol / mol).

[0047] Product detection method:

[0048] High-perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com