Preparation of superoxide anion sensor based on noble metal alloy/carbon composite material

A technology of superoxide anion and carbon composite material, applied in the field of sensors, can solve the problems of lack of solid enzyme interface, narrow linear range, low sensitivity, etc., and achieve the effects of good stability and repeatability, wide linear range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

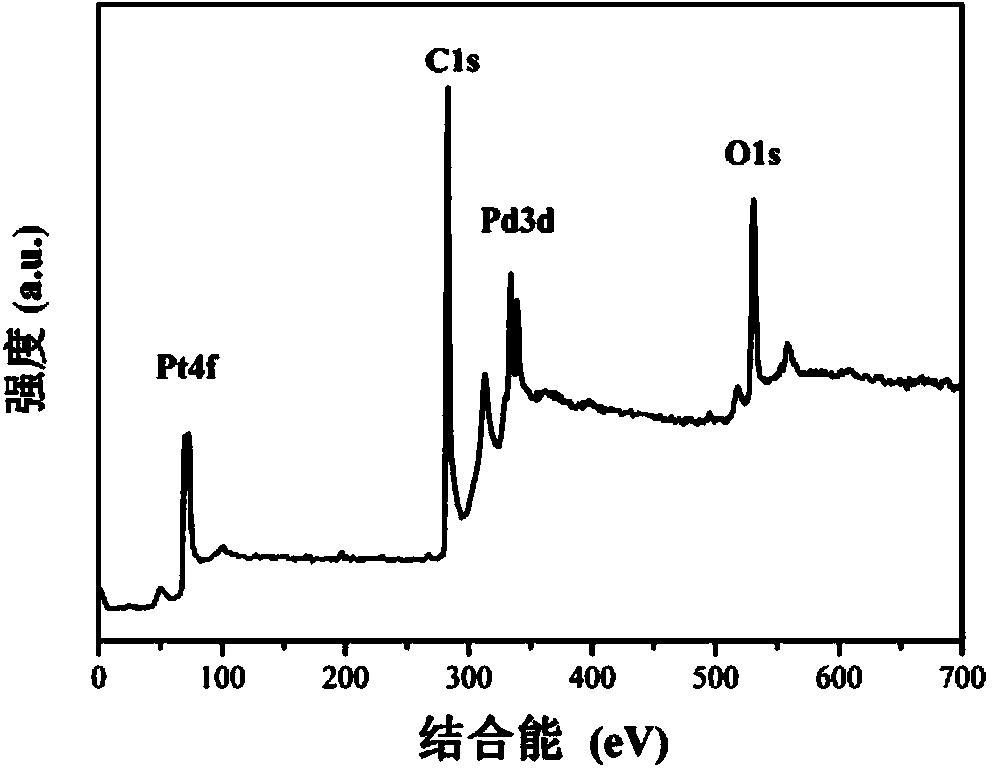

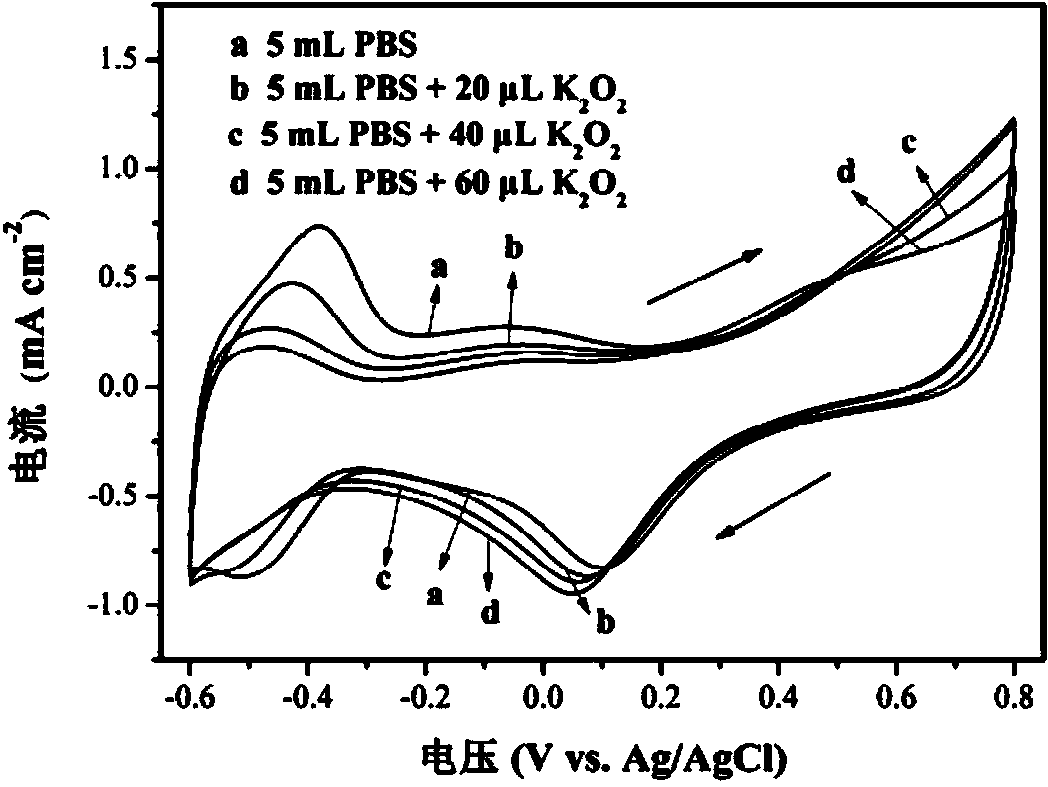

Image

Examples

Embodiment 1

[0053] Preparation of Pd-Pt / MWCNTs

[0054] (1) Functionalization of carbon nanotubes

[0055] Dissolve 1g MWCNTs into 50ml, 30%H 2 o 2 , sonicated for 4h to disperse the MWCNTs uniformly in the solution. Then filter with a 450nm membrane, wash with ultrapure water three times, and vacuum dry at 45°C for 12h. The MWCNTs treated above were added into the mixed solution of nitric acid and sulfuric acid (HNO 3 :H 2 SO 4 =1:3), 80 after 30min of ultrasound. The acidification reaction was carried out under reflux for 8 h at ℃ to introduce oxygen-containing groups such as carboxyl and hydroxyl groups on the surface of MWCNTs to increase the water solubility of MWCNTs. The product was washed with ultrapure water until neutral. Dry in a vacuum oven at 45°C before use.

[0056] (2) Preparation of Pd-Pt / MWCNTs

[0057] A: Take 10 mg of acidified MWCNTs in a small beaker, add 10 ml (water: ethylene glycol = 1: 1) mixed solution, and sonicate for 30 minutes to disperse MWCNTs ev...

Embodiment 2

[0062] Preparation of SOD / Pt-Pd / MWCNTs / SPGE Electrode

[0063] (1) Preparation of screen-printed gold film electrode (SPGE)

[0064] Strictly speaking, the screen-printed gold electrode is not simply a screen-printed electrode, because its preparation not only uses screen printing technology but also combines vacuum evaporation technology. Design drawings include (1) conductive silver layer, (2) Ag / AgCl reference layer, (3) carbon counter electrode layer, (4) insulating layer and (5) gold mask. The specific preparation process is as follows: The specific preparation steps are: (1) Print conductive silver paste on the PET substrate to form electrode strips, and heat-cure in an oven at 120° C. for 40 minutes. (2) Print the Ag / AgCl reference layer and heat cure it at 80°C for 10min. The final electrode area is 35mm×12mm (length×width), and the diameter of the working end is 3mm. (3) Print conductive carbon paste to form a carbon counter electrode layer, and heat-cure at 71°C fo...

Embodiment 3

[0071] Preparation and functionalization of graphene

[0072] Use the Hummers method to prepare graphene oxide and functionalize its surface. The specific method is as follows: First, add 20g NaCl to 1g graphite powder, shake for 10-15min, then filter and wash off NaCl, and dry in an oven at 70°C for 30min; then transfer Add 23mL concentrated sulfuric acid to a 250mL round bottom flask, stir at room temperature for 24h; then heat to 40°C in a water bath, add 100mg NaNO 3 , stirred for 5min to dissolve, slowly added 500mg KMnO 4 , add 3mL of water after 5min, add 3mL of water after 5min, add 40mL of water after 5min, remove from the water bath after 15min, add 140mL of water, add 10mL of 30% H 2 o 2 Neutralize unreacted KMnO 4 ; Finally, the solution obtained is subjected to centrifugation (5000rpm, 15min), and the lower layer solid matter is centrifugally washed with 100mL ultrapure water and 100mL5% HCl after centrifugation, and then washed with a large amount of water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com