Magnetism polymer nanometer microsphere material capable of degrading ring structure, as well as preparation method and application of magnetism polymer nanometer microsphere material

A technology of nano-microspheres and polymers, applied in the field of biomedicine, can solve the problems of unfavorable therapeutic effect and low drug loading, and achieve the effects of high drug loading rate, high drug loading, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

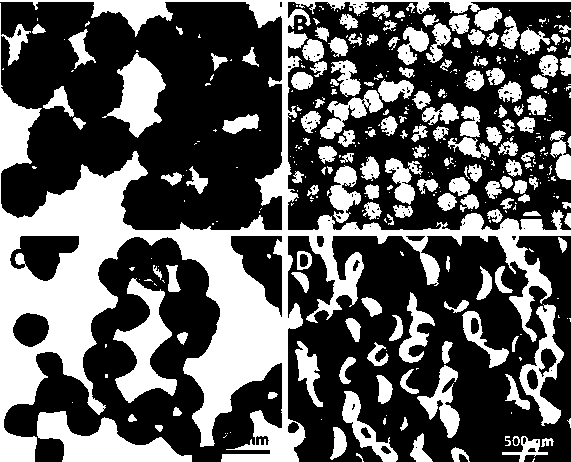

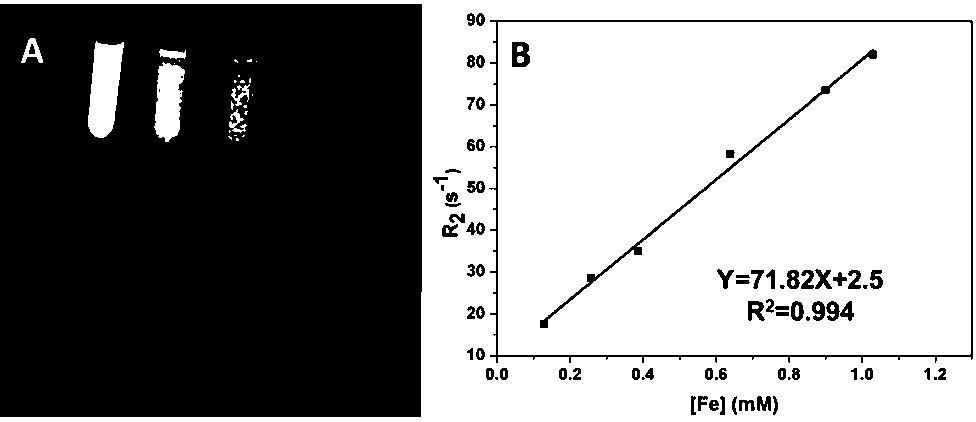

[0032] Example 1: Preparation of magnetic polymethacrylic acid (PMAA) nanospheres with degradable bell structure

[0033] (1) Polyglutamic acid (PGA) stabilized Fe 3 o 4 Synthesis of Magnetic Clusters: FeCl 3 ·6H 2 O (1.35 g), NH 4 Ac (3.85 g) and PGA (0.50 g) were added to ethylene glycol (70 mL), heated to 160 o C, after reacting for 1 h, the mixed solution was transferred to an autoclave (100 mL) and placed in a 200 o C in an oven for 16 h. After cooling to room temperature, centrifuge to remove solvent and unreacted monomer, wash with ethanol and water repeatedly for 3-5 times, and place in a vacuum oven for 45 o C dried for 24 h to obtain polyglutamic acid-stabilized Fe 3 o 4 magnetic cluster.

[0034] (2) Synthesis of magnetic nanospheres coated with a monolayer of uncrosslinked PMAA: polyglutamic acid (PGA) stabilized Fe 3 o 4 Magnetic clusters (100 mg), MAA (500 mg), AIBN (16mg) and acetonitrile (40 mL), added to a 100 mL one-necked bottle, heated to 100 ...

Embodiment 2

[0037] Example 2: Preparation of magnetic polyacrylic acid (PAA) nanospheres with degradable bell structure

[0038] (1) Polyglutamic acid (PGA) stabilized Fe 3 o 4 Synthesis of Magnetic Clusters: FeCl 3 ·6H 2 O (1.35 g), NH 4 Ac (4.15 g) and PGA (0.50 g) were added to ethylene glycol (70 mL), heated to 160 o C, after reacting for 1 h, the mixed solution was transferred to an autoclave (100 mL) and placed in a 200 o C in an oven for 16 h. After cooling to room temperature, centrifuge to remove solvent and unreacted monomer, wash with ethanol and water repeatedly for 3-5 times, and place in a vacuum oven for 45 o C dried for 24 h to obtain polyglutamic acid-stabilized Fe 3 o 4 magnetic cluster.

[0039] (2) Synthesis of magnetic nanospheres coated with monolayer uncrosslinked PAA: polyglutamic acid (PGA) stabilized Fe 3 o 4 Magnetic clusters (100 mg), AA (400 mg), AIBN (12mg) and acetonitrile (40 mL), added to a 100 mL single-necked bottle, heated to 100 o C, refl...

Embodiment 3

[0042] Example 3: Preparation of magnetic hydroxypolyethyl methacrylate (PHEMA) nanospheres with degradable bell structure

[0043] (1) Fe stabilized by chitosan 3 o 4 Synthesis of Magnetic Clusters: FeCl 3 ·6H 2 O (1.35 g), NH 4 Ac (3.85 g) and chitosan (0.60 g) were added to ethylene glycol (70 mL), heated to 160 o C, after reacting for 1 h, the mixed solution was transferred to an autoclave (100 mL) and placed in a 200 o C in an oven for 16 h. After cooling to room temperature, centrifuge to remove solvent and unreacted monomer, wash with ethanol and water repeatedly for 3-5 times, and place in a vacuum oven for 45 o C dried for 24 h to obtain chitosan-stabilized Fe 3 o 4 magnetic cluster.

[0044] (2) Synthesis of magnetic nanospheres coated with a monolayer of uncrosslinked PHEMA: Chitosan-stabilized Fe 3 o 4 Magnetic clusters (100 mg), HEMA (500 mg), AIBN (16mg) and acetonitrile (40 mL), added to a 100 mL single-necked bottle, heated to 100 o C, reflux reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com