A Porous Single Crystal Gallium Nitride Micro/Nanotube Array with Controllable Inner Diameter and Its Preparation Method

A nanotube array and gallium nitride microtechnology, which is applied in the field of porous single crystal gallium nitride micro/nanotube arrays and their preparation, can solve the problem that metal organic raw materials are toxic, unfavorable for large-scale industrial production, and metal organic gallium sources have Toxicity and other problems, to achieve the effect of easy mass production, special morphology and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

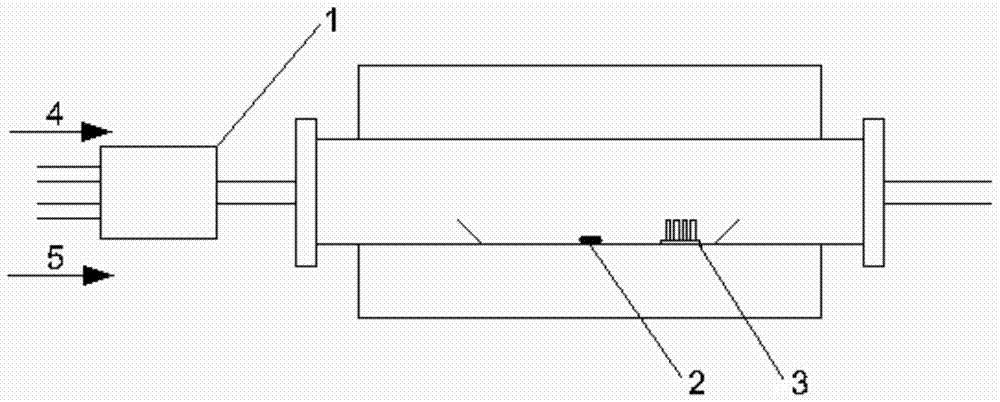

[0047] (1) Use such as figure 2 The shown chemical vapor deposition device will be untreated Ga / Ga 2 o 3 The mixed powder 2 (molar ratio 4:1) is placed in the middle of the quartz boat, followed by a zinc oxide micro / nanowire array 3 with an average diameter of about 800 nm, and the quartz boat is placed in the quartz tube so that the gallium source is located The central area of the tube furnace. Use a vacuum pump to exhaust the air in the quartz tube, and then introduce an inert gas, so that the oxygen in the quartz tube can be exhausted as much as possible through three cycles. Then continuously blow 200 sccm of inert gas into the quartz tube for 30 minutes to exhaust oxygen as much as possible. Then start heating, the inert gas flow rate is maintained at 100 sccm during the heating process, and the heating rate is controlled to be 10 °C / min;

[0048] (2) When the temperature in the central area of the tube furnace reaches 950°C, turn off the inert gas, and feed am...

Embodiment 2

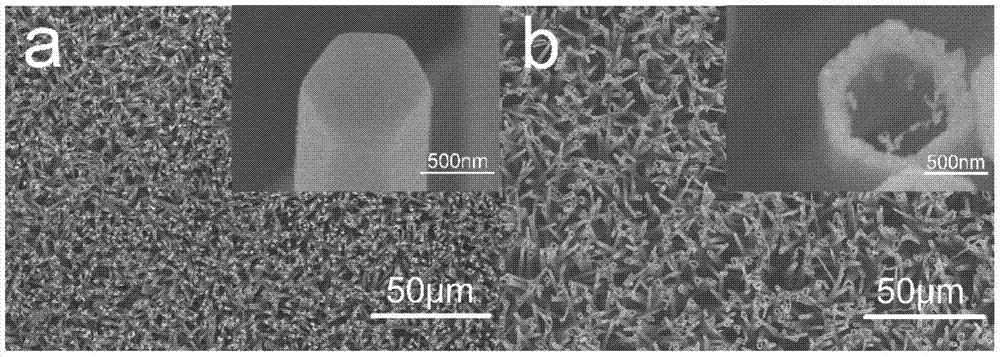

[0053] A porous single crystal gallium nitride microtube array was prepared according to the method in Example 1. The difference is that Ga / Ga 2 o 3 The molar ratio of the mixed powder is 3:1, and the average diameter of the zinc oxide micro-wire arrays used for epitaxial growth is about 2 μm. When the temperature in the central area of the tube furnace reaches 850°C, the inert gas is turned off, and ammonia gas and hydrogen / argon gas mixture are introduced at the same time. The flow rate of ammonia gas is controlled at 10 sccm, the volume ratio of hydrogen gas to argon gas is 1:5, and the flow rate is controlled. At 30 seem; after 5 h of reaction, the tube furnace was turned off. The scanning electron micrograph of the product that present embodiment obtains is as Figure 5 as shown in b. This result is similar to the result of Example 1, and a porous gallium nitride micro / nanotube array is also grown, and the average inner diameter of the microtubes is about 2 μm.

Embodiment 3

[0055] A porous single crystal gallium nitride microtube array was prepared according to the method in Example 1. The difference is that Ga / Ga 2 o 3 The molar ratio of the mixed powder 2 is 3:2, and the average diameter of the zinc oxide micro-wire array used for epitaxial growth is about 5 μm. When the temperature in the central area of the tube furnace reaches 1050°C, the inert gas is turned off, and ammonia gas and hydrogen / argon gas mixture are introduced at the same time. The flow rate of ammonia gas is controlled at 50 sccm, the volume ratio of hydrogen gas to argon gas is 1:11, and the flow rate is controlled. At 90 seem; after 0.5 h of reaction, the tube furnace was turned off. The scanning electron micrograph of the product that present embodiment obtains is as Figure 6 as shown in b. The result of this example is similar to that of Examples 1 and 2, and uniform and porous gallium nitride microtube arrays are also grown, and the average inner diameter of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com