Bio-control bacillus subtilis surfactin separation and purification method

A technology of Bacillus subtilis and surfactin, applied in chemical instruments and methods, analytical materials, material analysis by electromagnetic means, etc., can solve the problems of decreased antifungal activity of mutant strains, loss of antifungal activity of mutant strains, reduction, etc. , to achieve the effect of broad antibacterial spectrum, good thermal stability, high research and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

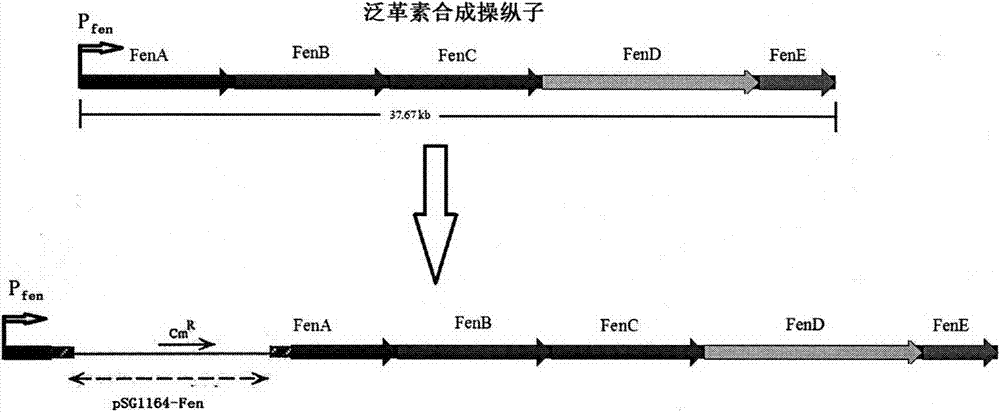

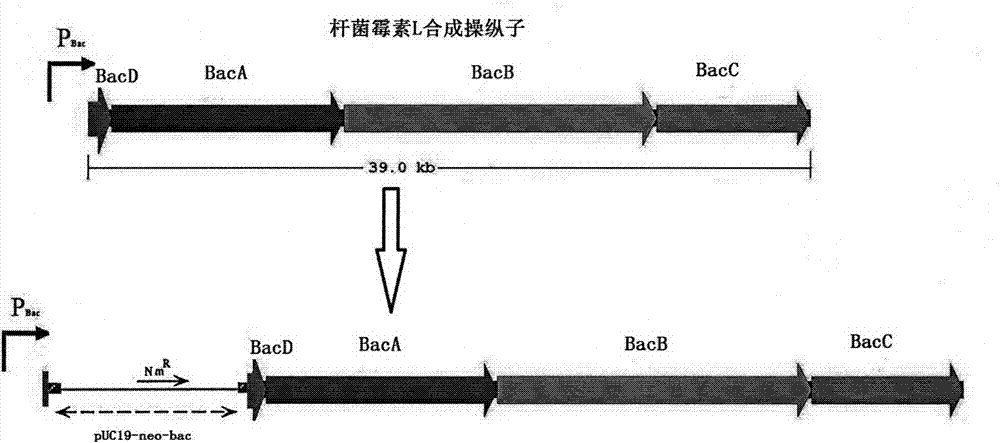

[0030] Example 1 Construction of Bacitracin L and Ubiquitin Synthetic Gene Mutants

[0031]The neomycin resistance gene fragment was excised from the plasmid vector pBEST501 by enzyme digestion, cloned into the pUC19 plasmid vector to construct the recombinant plasmid vector pUC19-neo; amplified from the genomic DNA of Bacillus subtilis Bs916 by polymerase chain reaction (PCR) The partial gene fragment IBacD synthesized by bacitracin L was cloned into the pUC19-neo plasmid vector after enzyme digestion and enzyme ligation to construct the single exchange knockout plasmid vector pUC19-neo-bac; the polymerase chain reaction (PCR) method was used to obtain the The partial fragment IFenA of the ubiquitin synthesis gene was amplified from the genomic DNA of Bacillus subtilis Bs916, and the amplified fragment was cloned into the pSG1164 plasmid vector after digestion and enzyme ligation to construct the single crossover knockout plasmid vector pSG1164-Fen; the constructed single cros...

Embodiment 2

[0032] The preparation of embodiment 2 surfactin crude extracts

[0033] The double mutant strain BBFM of biocontrol Bacillus subtilis Bs-916 is transferred in the LB nutrient solution (the LB nutrient solution is tryptone 10g / L, yeast powder 5g / L, sodium chloride 5g / L, pH7 .0, cultured with shaking at 28°C and 180r / min for 72h. The fermentation broth was centrifuged at 4°C and 5000r / min for 30min to remove the bacteria, and the supernatant was adjusted to pH 2.0 with concentrated hydrochloric acid to precipitate overnight. Centrifuged at 8000r / min After 25 minutes, the precipitate was obtained, and the precipitate was extracted with methanol, and the extract was subjected to 0.22 μmol L -1 After the microporous membrane, the crude surfactin sample was prepared.

Embodiment 3

[0034] The purification of embodiment 3 surfactin

[0035] The crude extract was diluted with deionized water into a 30% methanol aqueous solution, the pH value was adjusted to 7.0, and then loaded on NH 2 The solid phase extraction column is eluted with 50% methanol aqueous solution, 100% methanol, 0.5% formic acid methanol solution, 1% formic acid methanol solution, 2% formic acid methanol solution gradient elution, and the 1% formic acid methanol elution solution contains the target compound.

[0036] Adjust the pH value of the methanol eluting solution containing 1% formic acid to 7.0, dry and concentrate with nitrogen, dilute with deionized water to 30% methanol aqueous solution, and then load the sample on a C18 solid phase extraction column; use 40% of 3 times the column volume , 50%, 60%, 70%, 90% methanol aqueous solution gradient elution, wherein the pure product of surfactin was obtained in the eluent containing 90% methanol water, the purity was 95%, a total of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com