Oriented polymer nanometer fibrocyte culture plate and preparation method thereof

A nanofiber and cell culture technology, which is applied in biochemical equipment and methods, tissue cell/virus culture devices, and methods of supporting/fixing microorganisms, etc. Industrial application and other issues, to achieve the effect of no cytotoxicity, maintaining cell viability, and facilitating cell adhesion and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of oriented polymer nanofiber 6-well cell culture plates:

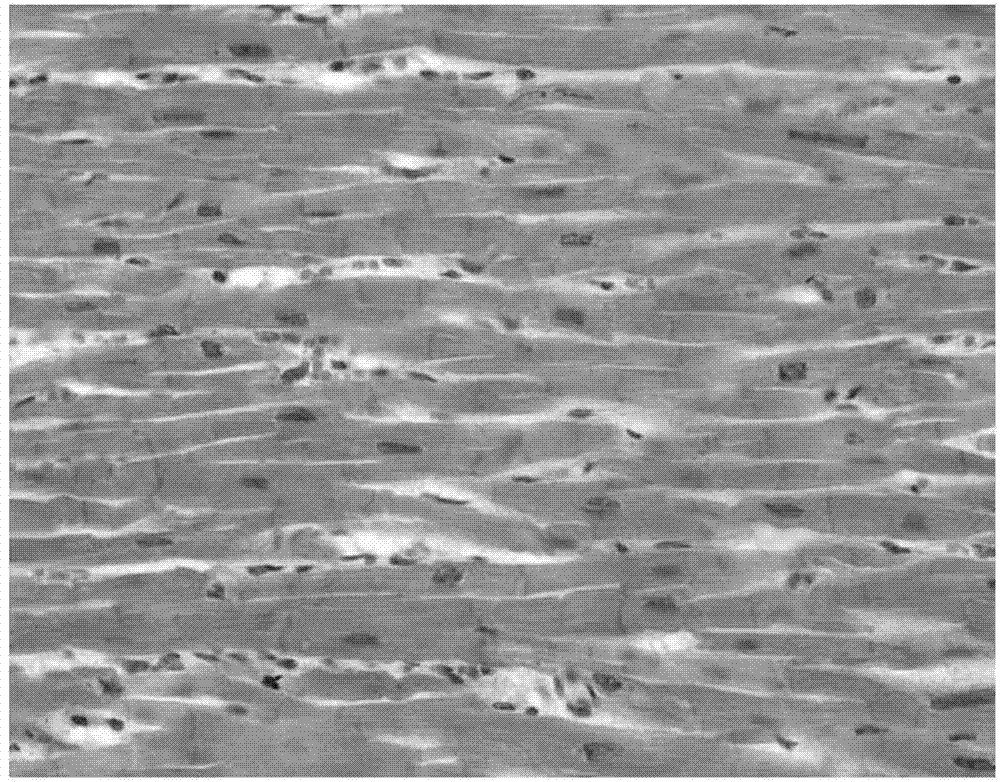

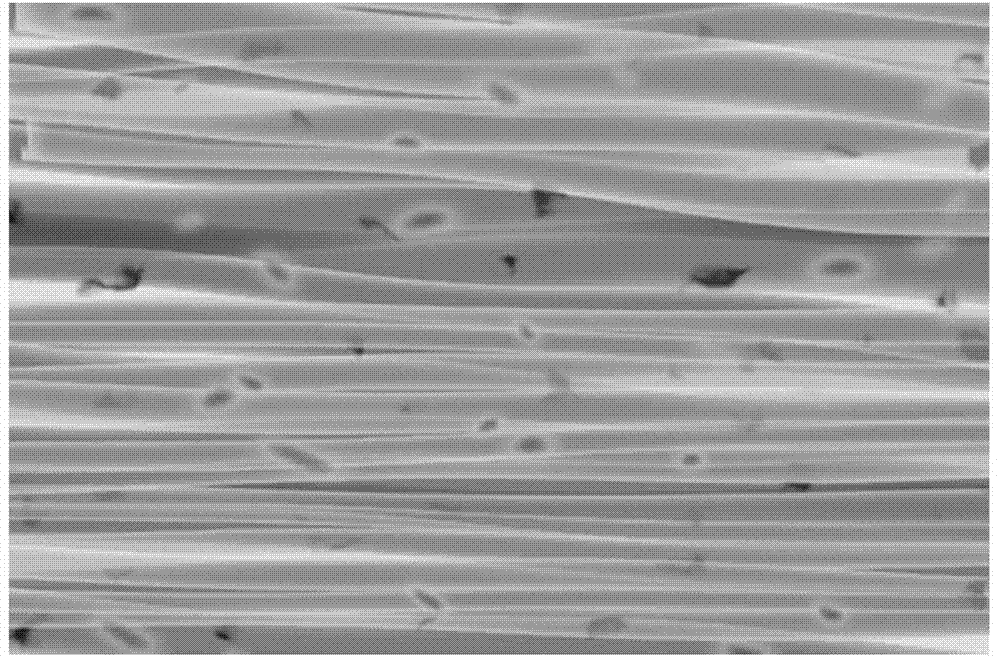

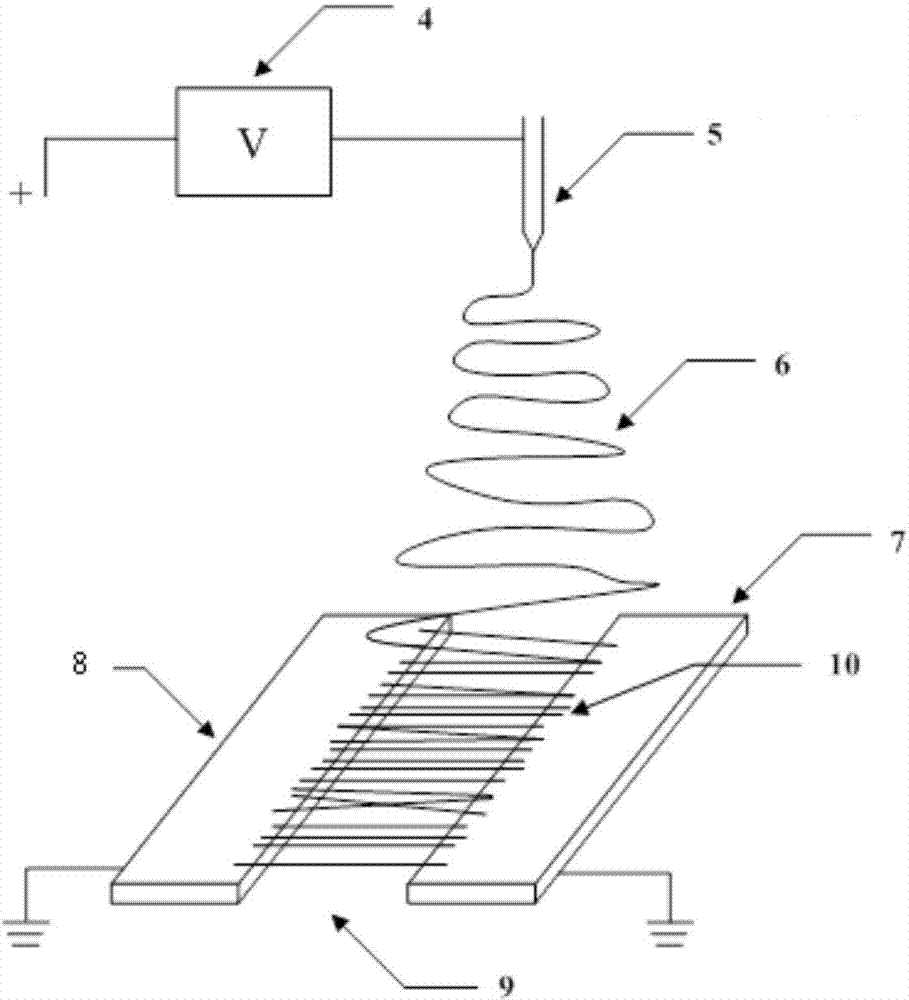

[0069] A standard 6-well flat-bottomed cell culture plate made of ordinary polystyrene, which is sterilized as the fixed object of the oriented polymer nanofiber scaffold. First, mix the polymer raw materials PLGA, PCL and collagen at a mass ratio of 7: 2.5: 0.5, add a small amount of NGF (nerve growth factor) as the bioactive component to the polymer raw materials, the mixing ratio is 100:1, add 1:1 The mass fraction of the solute in the dichloromethane / chloroform mixed solvent was about 10 wt%, and it was fully dissolved to prepare the electrospinning solution. Then, the electrospinning solution was sucked into the electrospinning syringe, and the electrospinning was carried out under the condition that the needle tip voltage of the syringe was 30 kV and the pump supply volume was 0.030 ml / min-0.050 ml / min, and the obtained fiber diameter was Between 50nm~300nm. The obtained oriented PLGA / PCL / co...

Embodiment 2

[0076] Preparation of oriented polymer nanofiber 24-well cell culture plates:

[0077]A 24-well standard flat-bottomed cell culture plate made of ordinary polystyrene, which is sterilized and fixed as an orientation polymer nanofiber scaffold. First, the polymer raw material silk fibroin was dissolved in a supersaturated LiBr aqueous solution with a silk fibroin concentration of 10 wt%, and then after successive steps of dilution, centrifugation, filtration, dialysis and concentration, the silk fibroin concentration was about 30 wt%. % concentrated aqueous solution. Add a small amount of calcium chloride (concentration is about 0.3 mol / L) to the concentrated silk fibroin solution, and then add a small amount of BMPs (bone morphogenetic protein) and nano-hydroxyapatite to the polymer as bioactive components Raw materials, the mixing ratios of the two and silk fibroin are 1:50 and 1:200 respectively, fully dissolved and dispersed to obtain an electrospinning solution for use. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com