Method and Application of Improving the Performance of Material Surface Modification Layer

A surface modification layer and performance technology, applied in the field of surface modification of materials, can solve the problems of weak weather resistance and wear resistance, poor bonding force, not yet suitable for practical use, etc., to achieve dense film layer and enhance bonding force , Improve the effect of binding force and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

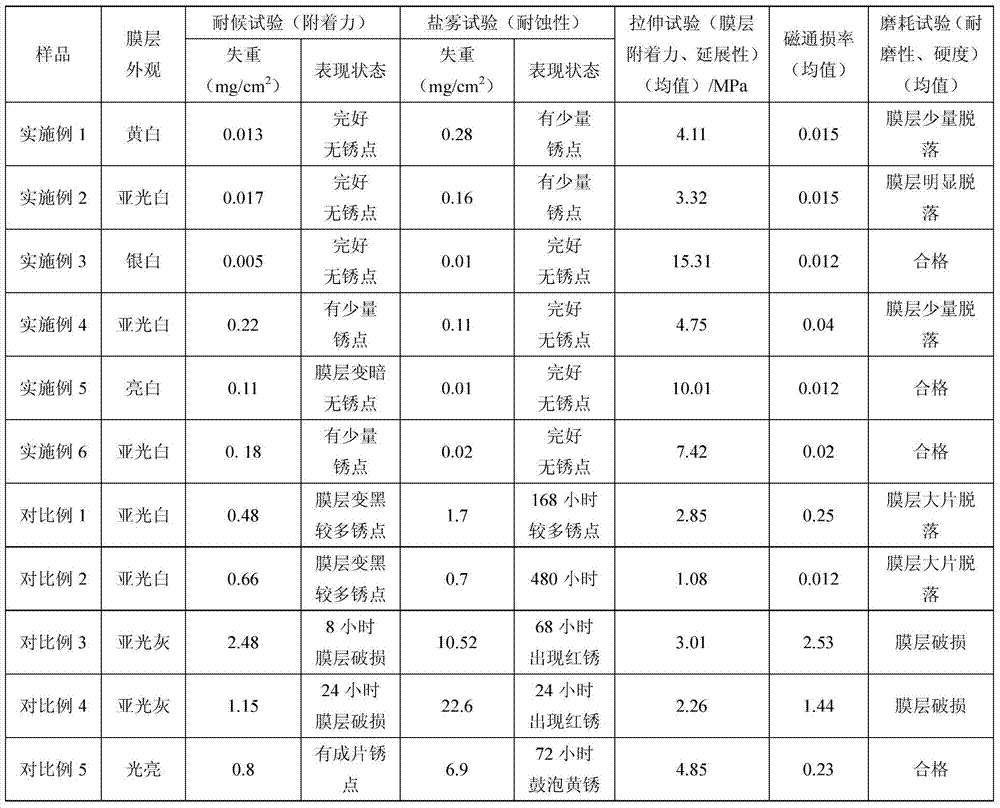

Embodiment 1

[0094] (1) Nd, B, Co, Cu, Al, Zr, Fe raw materials according to mole percentage Nd 25.8%, B 0.98%, Co1%, Cu0.27%, Al 0.18%, Zr 0.4%, Febal ratio, alloy The total mass is 5kg, and put into the vacuum induction melting furnace at the same time, through the process of charging - vacuuming - preheating - argon filling - high power smelting - low power stirring - casting and other processes, the smelted alloy liquid (copper rollers are refrigerated Water cooling, the speed is about 35-50 rpm) to make thin slices with a thickness of about 0.3-0.4mm and good crystallization, and select alloy quick-setting sheets with smooth performance, uniform thickness, and bright white color to prepare powder for use.

[0095] (2) Put the selected quick-setting tablets into the special hydrogen crushing furnace, and carry out coarse crushing through positive and negative pressure detection-hydrogen absorption-heating-vacuum dehydrogenation-cooling-out of the furnace, etc. In nitrogen-protected glo...

Embodiment 2

[0109] Steps (1)~(5) are identical with steps (1)~(5) in embodiment 1;

[0110] The difference is as follows:

[0111] (6) Use gasoline and a NaOH solution with a concentration of 2mol / L to remove the oil stains on the surface of the small cylinder successively, and then place it in a sandblasting machine for surface derusting and descaling treatment (the diameter of the steel shot is: 0.1~ 0.3mm, sandblasting time: 20 minutes). Afterwards, the surface of the small cylinder is polished on a cylindrical grinder (polishing time: 30 minutes), and finally the polished small cylinder is placed in a mixture of absolute ethanol and acetone, and the surface of the magnet is further decontaminated under the action of ultrasonic waves Processing (ultrasonic frequency: 100 Hz, cleaning time: 10 minutes), take out the small cylinder and let it dry naturally at room temperature for later use.

[0112] (7) While cleaning the surface of the magnet, get sodium silicate and add zinc silicate...

Embodiment 3

[0118] Steps (1)~(5) are identical with steps (1)~(5) in embodiment 2;

[0119] (6) Use gasoline and NaOH solution with a concentration of 2% to remove the oil stains on the surface of the small cylinder after slicing, and then place it in the sandblasting machine for surface derusting and descaling treatment (the diameter of the steel shot is: 0.1 to 0.3 mm, sandblasting time: 30 minutes). Afterwards, the surface of the small cylinder is polished on a cylindrical grinder (polishing time: 40 minutes), and finally the polished small cylinder is placed in a mixture of absolute ethanol and acetone, and the surface of the magnet is further decontaminated under the action of ultrasonic waves Processing (ultrasonic frequency: 100 Hz, cleaning time: 20 minutes), take out the small cylinder and let it dry naturally at room temperature for later use.

[0120] (7) While cleaning the surface of the magnet, get sodium water glass and add zinc silicate to fully mix (zinc silicate accounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com