An improved biological preservative for aquatic products, its preparation method and application

A technology of biological preservatives and aquatic products, applied in the direction of preserving meat/fish with chemicals, which can solve the problems of low enzyme production activity and complicated separation, and achieve the effects of simple operation, good sensory perception, and inhibition of spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the screening of producing glucose oxidase bacterial strain

[0038] The screening method of bacillus CAMT22370 of the present invention comprises the following steps:

[0039] (1) Enrichment of bacteria: Weigh 1g of sea mud and shake it evenly in a 9ml sterile seawater test tube, let it stand still, take the supernatant and dilute to 10 -2 , 10 -3 , l0 -4 After oscillating evenly, take 1 mL of sample solutions of different concentrations and inoculate them into each culture medium, and place them in an incubator at 30°C for upside-down cultivation.

[0040] (2) Primary screening: Dilute the enriched bacteria to about 10 4 / mL concentration, according to the product H 2 o 2 Methylene blue can be oxidized to colorless, and a chromogenic medium containing a concentration gradient of methylene blue is designed. The diluted bacterial suspension is inoculated on the chromogenic medium by the dilution coating method, and after culturing at 30°C for 48 hours...

Embodiment 2

[0042] Embodiment 2: Identification of producing glucose oxidase strain

[0043] The strains screened in Example 1 were identified by morphological and molecular biological methods.

[0044] The morphological identification mainly adopts the observation of colony morphology and microscopic morphology, and the physiological and biochemical identification adopts glycolysis test, starch hydrolysis test, V-P test, methyl red test, oxidase test, three sugar iron agar test and sulfuration test according to the metabolic process of the strain. The method of hydrogen indigo matrix-dynamic agar test was carried out, and the identification of molecular biology was carried out by 16SrDNA sequencing and comparison. The strains were assigned based on the results of morphological, physiological, biochemical and biomolecular identifications.

[0045] Among them, molecular biology identification firstly uses bacterial DNA extraction kit to extract genomic DNA, and then uses universal primers...

Embodiment 3

[0048] Embodiment 3: Bacillus CAMT22370 liquid fermentation produces glucose oxidase condition optimization

[0049] In this experiment, the enzyme production conditions of the screened Bacillus CAMT22370 were optimized. Specifically, it is mainly to optimize the culture medium and culture conditions for the production of glucose oxidase by liquid fermentation. Unless otherwise specified, the following percentages are percentages by weight.

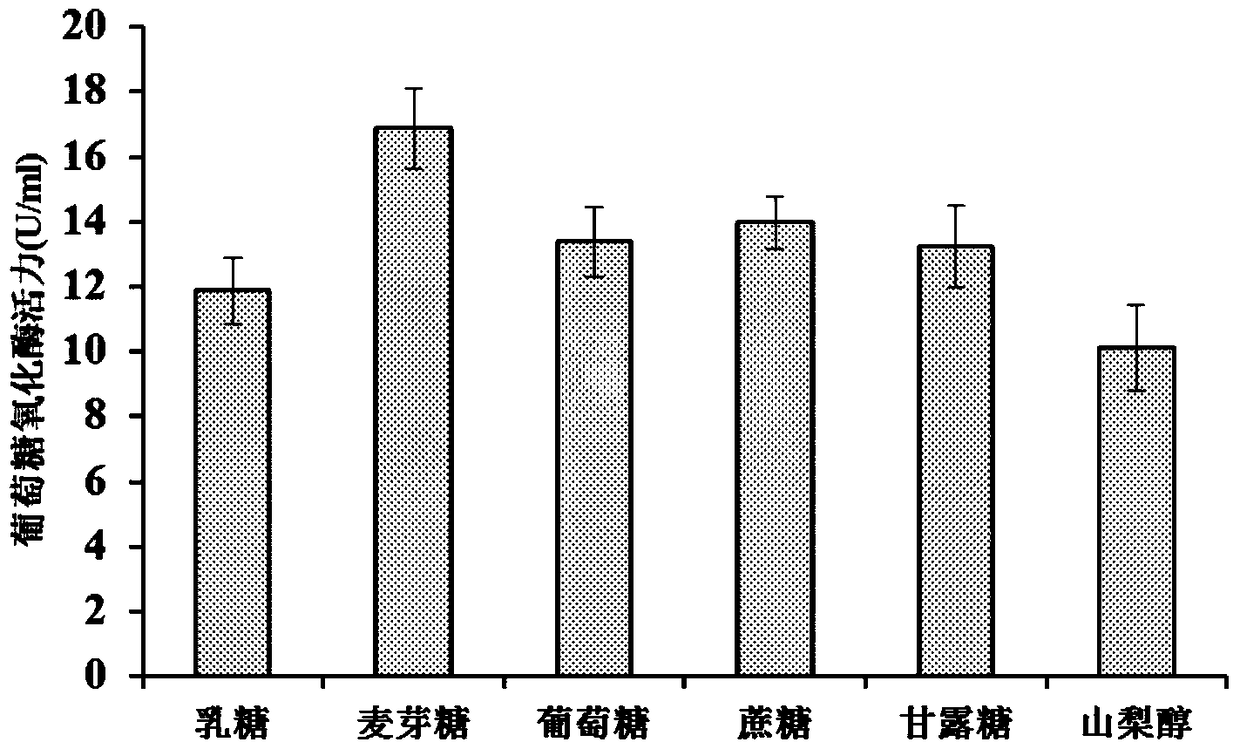

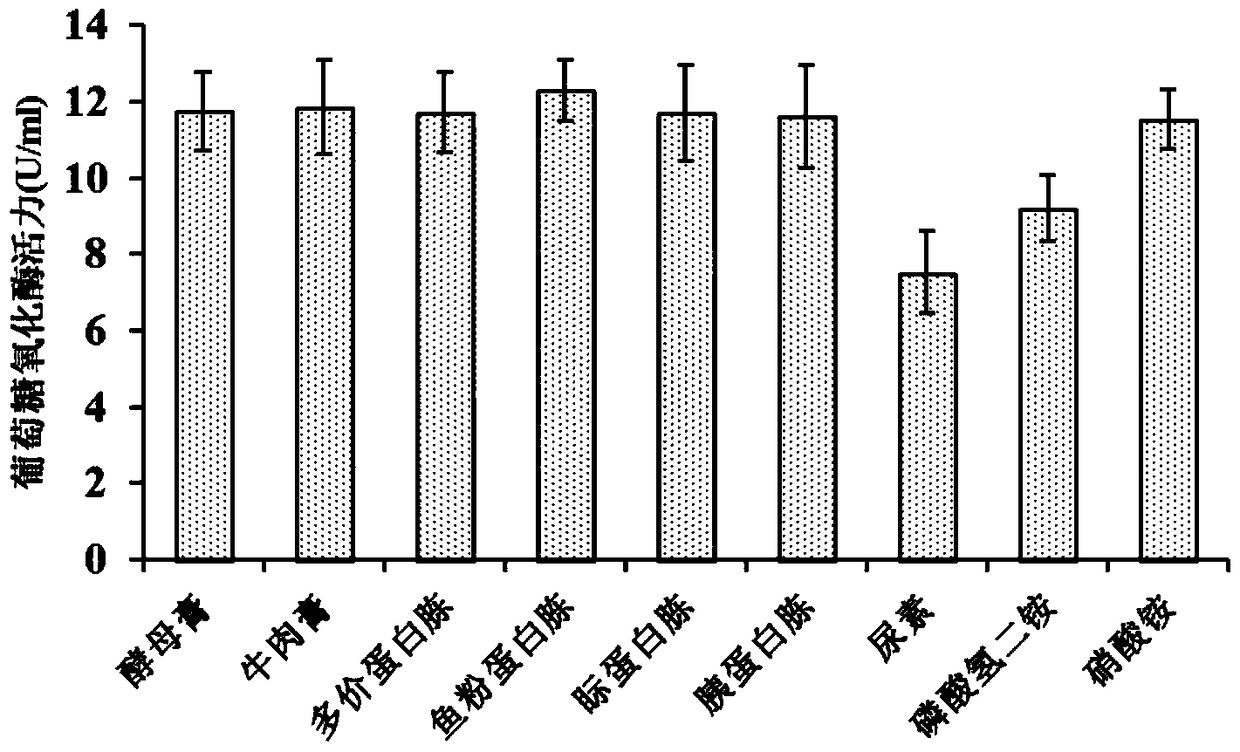

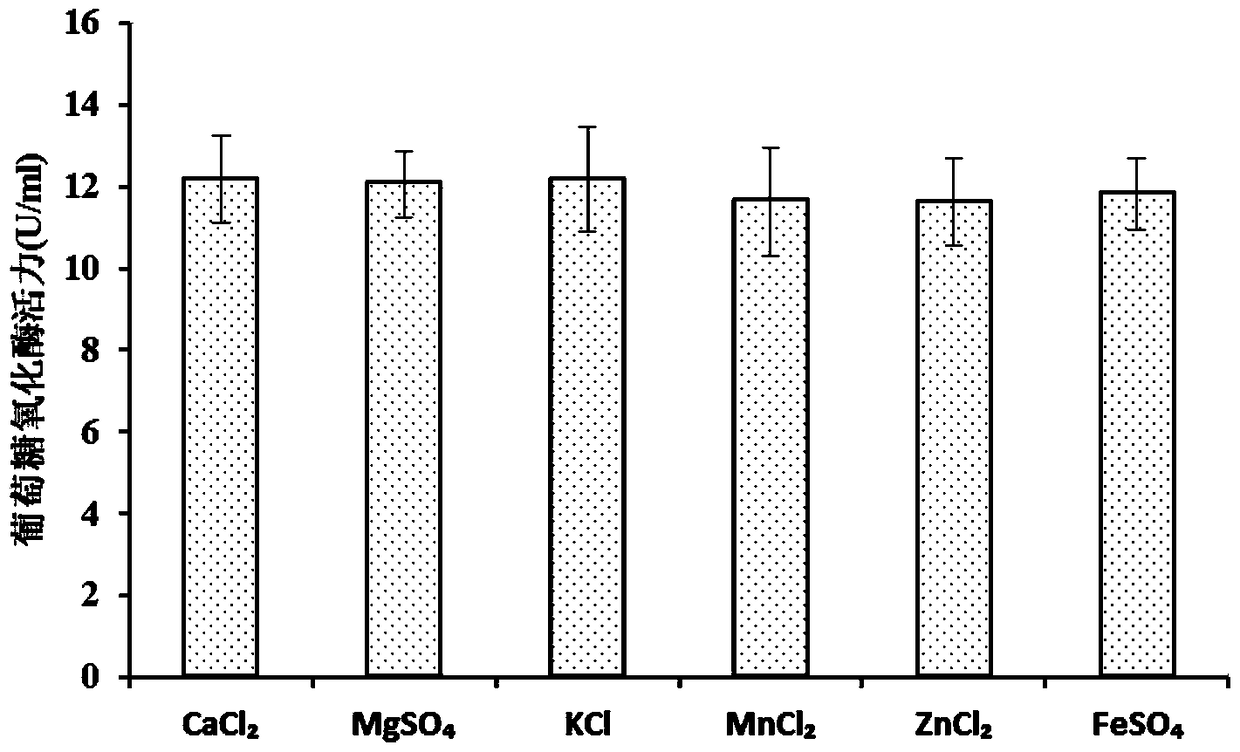

[0050] 1. Screening of carbon source types: On the basis of 0.3% beef extract and 0.5% sodium chloride, glucose, lactose, sucrose, maltose, sorbitol, and mannose were added in an amount of 1% to make a carbon source containing only a certain carbon source. One carbon source medium. Fermentation inoculum volume is 5% (volume ratio), rotation speed 150rpm, 28 ℃ constant temperature fermentation culture for 72 hours, enzyme activity is measured, and the enzyme activity is used as the judgment standard. The carbon source with the largest en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com