Absorbable tubular stent and preparation method and application thereof

A tubular, tube-walled technology, applied in the field of tubular stent materials and their preparation, and tubular stent materials, to achieve good mechanical strength, broad market prospects, and good blood flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

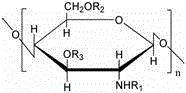

[0016] Embodiment 1: the preparation of acylated chitosan

[0017] (1) Preparation of acylated chitosan 1: Weigh 20 g of chitosan powder (deacetylation degree 90.4%, molar percentage, the same below), add it to a glass reaction vessel, add 50 mL of acylating reagent acetic anhydride solution, add methanol 100ml, control the temperature at 10°C, add 1ml of perchloric acid solution with a concentration of 70% by weight under stirring as a catalyst, and stir for 18 hours. After the reaction is completed, filter and separate the solid and liquid, put the solid into 5% NaOH aqueous solution by weight, neutralize the acid and alkali, centrifuge, separate the solid and liquid, wash the solid with water to remove the salt, 95% ethanol (weight percentage , the same below) dehydration, heating and drying at 60°C to obtain acylated chitosan 1 with a degree of acylation of 72.5% (mole percentage, elemental analysis, the same below). Acylated chitosan 1 has an acetyl structure with an ac...

Embodiment 2

[0027] Example 2: Cytocompatibility and degradation absorption of acylated chitosan

[0028] Preparation of acylated chitosan diaphragm: Take 2 g of acylated chitosan powder with a degree of acetylation of 85%, add 100 ml of formic acid solution with a concentration of 80% by weight, stir and dissolve, and prepare a mixture with a weight-to-volume ratio of 2 % acylated chitosan glue. Measure 15ml of the acylated chitosan glue respectively, place them in a PP square plate with a side length of 50mm×50mm, and let it stand and dry in a fume hood. The dried membrane is placed in 2% NaOH aqueous solution for acid-base neutralization, washed with water until the pH is neutral, and dried to prepare the acylated chitosan membrane.

[0029] An acylated chitosan membrane with a diameter of 7 mm was prepared with a trephine, placed at the bottom of a 96-well cell culture plate, and fully infiltrated with DMEM medium plus 10% newborn bovine serum for 24 hours. Take the L929 cells in t...

Embodiment 3

[0033] Example 3: Preparation of Absorbable Tubular Material 1

[0034] Weigh 1.0 g of polylactic acid (molecular weight: 20,000), stir and dissolve in 50 ml of dimethylformamide (DMF), add 1.0 g of acylated chitosan 1 prepared in Example 2, stir and dissolve to obtain polylactic acid-acylated shell polysaccharide glue. Take a stainless steel rod pipe-making mold with a length of 10cm and a diameter of 6mm, connect it to the pipe-making mold interface on the pipe-making machine, turn on the pipe-making machine, rotate the stainless steel rod in the axial direction, and evenly mix the polylactic acid-acylated chitosan glue The ground coating is on the surface of the rotating stainless steel rod. With the volatilization of the solvent, continue to coat the polylactic acid-acylated chitosan glue, and spin dry at room temperature to obtain a tubular material with a tube wall thickness of 0.8 mm to 1 mm. Remove the stainless steel rod with the tubular material, soak it in hot wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com