A method for harmless treatment and recycling of aluminum ash

A harmless treatment, aluminum ash technology, applied in the field of metallurgical environmental protection, can solve the problems of unrealized industrial production scale, high production cost, restricted development, etc., and achieve great social value and economic and environmental protection benefits, high environmental protection benefits, and equipment. The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

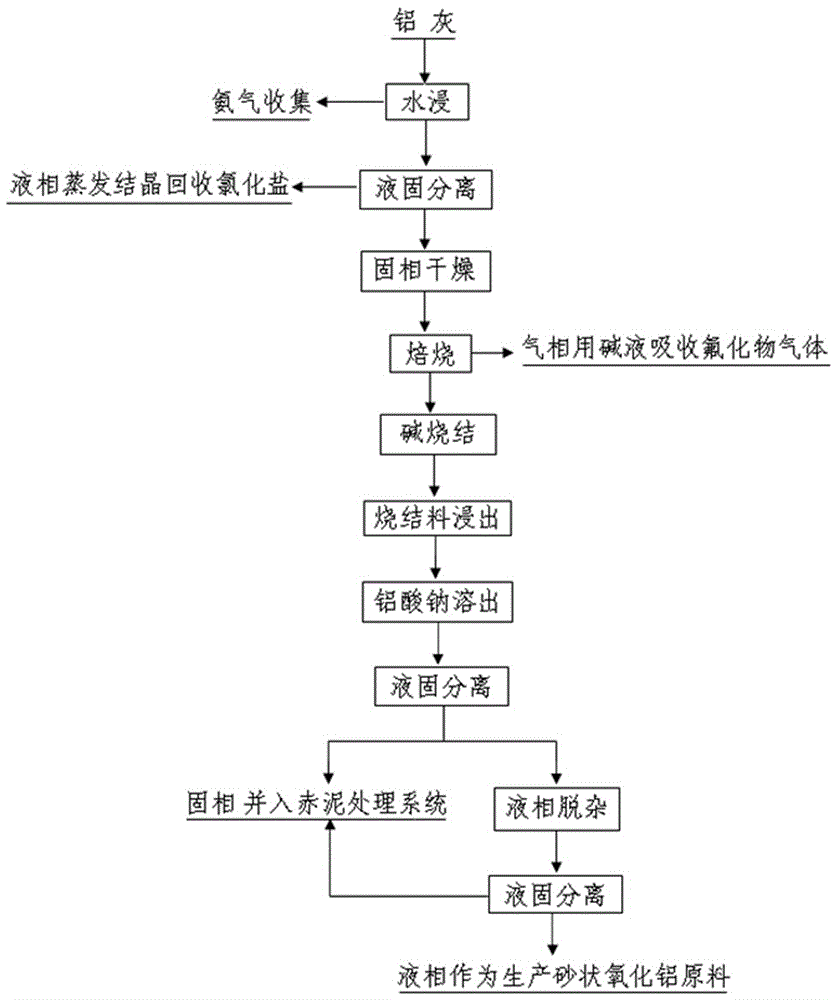

[0035]Take 100g of aluminum ash, add a liquid-solid ratio of 4:1, soak in water for 3 hours at 50 ° C, and use a gas collection device to recover the ammonia gas generated during the water immersion process. It was dried at 80°C for 24h, and the liquid produced during the water immersion process was recovered for evaporative crystallization to recover chloride salts. The dried aluminum ash was heated to 800°C in a closed furnace with a gas collection device. After 2 hours of heat preservation, the heat preservation was stopped. After cooling to normal temperature, the collection device was removed, and the material was taken out and ground. The fluoride produced during the roasting process is collected in a recovery unit as a raw material for the production of fluoride.

[0036] Take 50g of harmless aluminum ash, add sodium hydroxide and aluminum ash in a mass ratio of 1:0.9 and mix well, then sinter in a conventional furnace at 750°C for 3 hours, and then cool to room tempera...

Embodiment 2

[0038] Take 100g of aluminum ash, add liquid-solid ratio of 6:1, at 80 o Water immersion for 4 hours at C, and the ammonia gas generated during the water immersion process was recovered with a gas collection device during the water immersion. o Dry at C for 24h, and the liquid produced in the water immersion process is recovered for evaporative crystallization to recover chloride salts. Heat the dried aluminum ash to 1000°C in a closed furnace with a gas collection device, keep the temperature for 1.5 hours, stop the heat preservation, and after cooling to room temperature, remove the collection device, take out the material and grind it up. The fluoride produced during the roasting process is collected in a recovery unit as a raw material for the production of fluoride.

[0039] Take 50g of harmless aluminum ash, add sodium hydroxide and aluminum ash in a mass ratio of 1:1.2 and mix well, then sinter in a conventional furnace at 750°C for 3 hours, and then cool to room tempe...

Embodiment 3

[0041] Take 100g of aluminum ash, add liquid-solid ratio of 8:1, at 80 o Water immersion for 4 hours at C, and the ammonia gas generated during the water immersion process was recovered with a gas collection device during the water immersion. o Dry at C for 24h, and the liquid produced in the water immersion process is recovered for evaporative crystallization to recover chloride salts. The dried aluminum ash was heated to 850°C in a closed furnace with a gas collection device. After 1.5 hours of heat preservation, the heat preservation was stopped. After cooling to normal temperature, the collection device was removed, and the material was taken out and ground. The fluoride produced during the roasting process is collected in a recovery unit as a raw material for the production of fluoride.

[0042] Take 50g of harmless treated aluminum ash, add sodium carbonate and aluminum ash in a mass ratio of 1:1 and mix them evenly, at 1100 o Under the condition of C, it was sintered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com