Medical dental implant with surface biomimetic function and manufacturing method thereof

A dental implant and implant technology, which is applied in prosthesis, medical science, image data processing, etc., can solve the problems of unstable state of bioactive molecules, fast absorption of bioactive molecules of B, strong randomness, etc., and achieve early rapid and strong osseointegration, induction of osteocyte formation, and avoid random strong effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

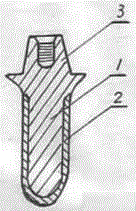

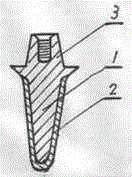

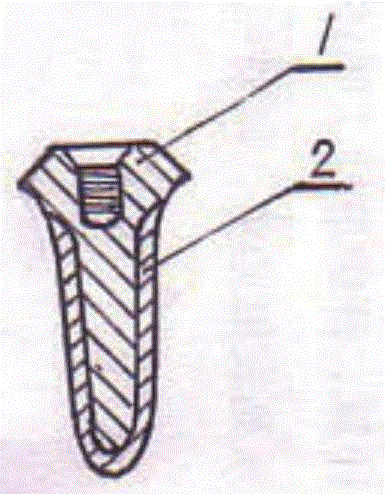

[0092] Such as Figure 1-7As shown, a complete implant denture is mainly composed of three parts: crown 4 , abutment 3 , and implant body 1 . The implant body 1 is the part combining the implant denture with the bone tissue, that is, the artificial tooth root, which is directly implanted into the patient's alveolar bone to play a role of fixation and support. The abutment 3 is located between the implant body 1 and the crown 4, and is connected to the implant body 1 apically, and connected to the crown 4 toward the coronal side, so as to connect the preceding and the following. Both the implant body 1 and the abutment 3 are not directly exposed to the oral cavity, and only the crown 4 is exposed to the oral cavity, which is the part that exerts the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com