Nano-metal oxide-minocycline nano sustained-release gel as well as preparation method and application thereof

A nano-metal and minocycline technology, which is applied in the field of treatment of acute and chronic periodontitis and gum disease, can solve the problems of milk precipitation, toxic substances, and particle size increase, so as to increase drug concentration, achieve good effect, and reduce toxicity. side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

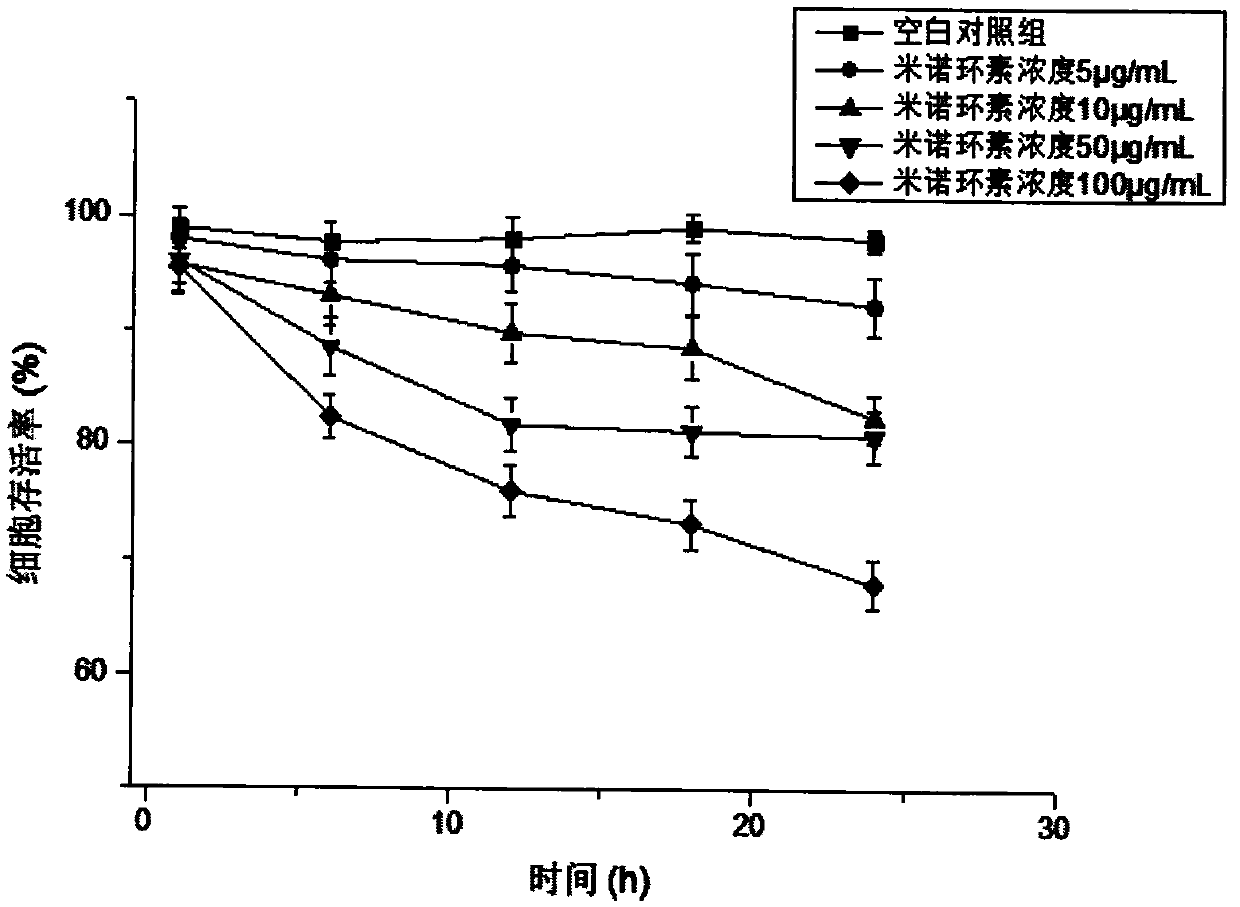

[0022] Embodiment 1: Preparation of nano zinc oxide-minocycline albumin gel

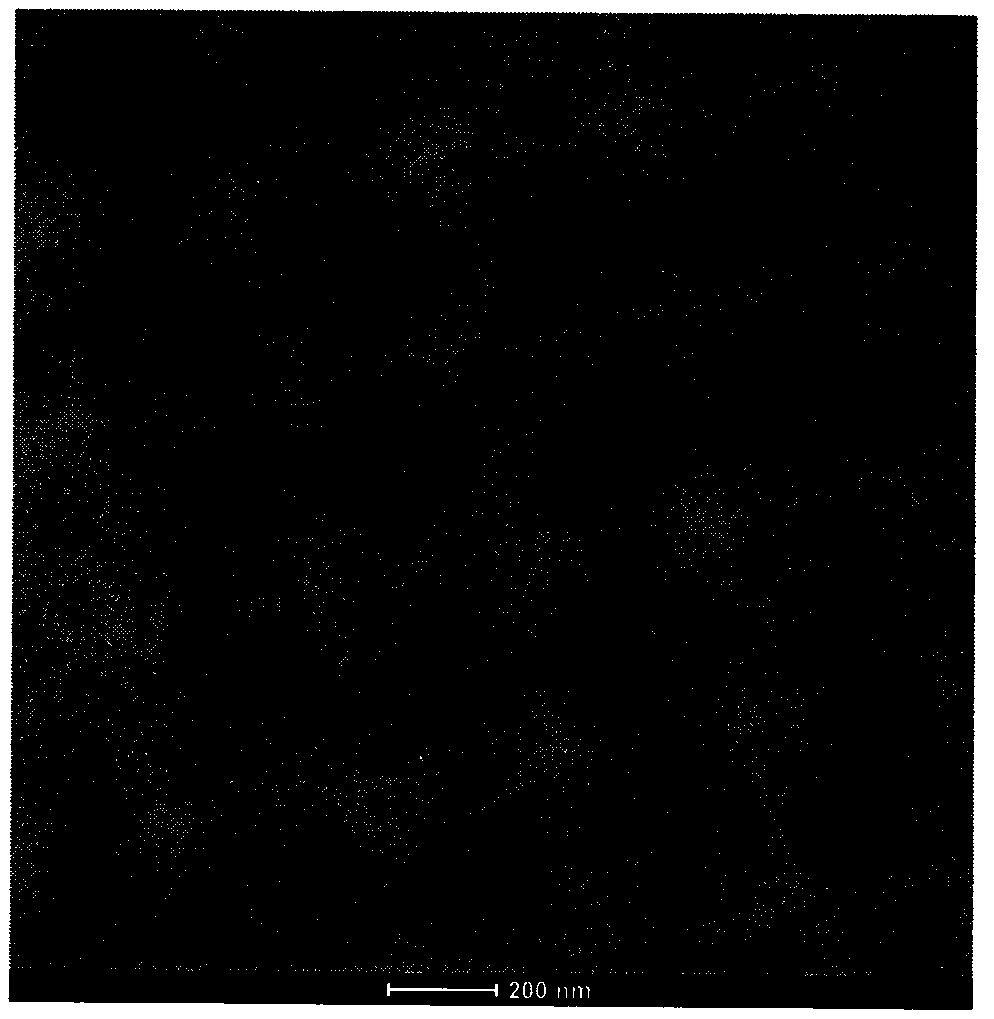

[0023] 1. Preparation of nano-zinc oxide

[0024] Cetyltrimethylammonium bromide CTAB0.3644g, cyclohexane 10ml are placed in the reaction bottle, isopropanol IPA5ml is precisely added dropwise, and stirred at room temperature until a uniform milky white emulsion is formed; keep stirring, and slowly pour into the solution Add 1 mol / L zinc acetate aqueous solution dropwise until the solution system is instantly clear. 3000-4000rpm rotating and centrifuging to obtain nanometer zinc oxide particles, the particle size of which is kept at 20-200 nanometers.

[0025] 2. Preparation of Minocycline Buffer

[0026] Put the content of 100mg minocycline hydrochloride capsules in a 500mL beaker, add 200mL distilled water to dissolve, stir well, filter and get the clear liquid, adjust the pH value to 7.5 with methanol solution of sodium hydroxide, and get 50% concentration of minocycline solution.

[0027] Tak...

Embodiment 2

[0034] Embodiment 2: Preparation of nanometer silver oxide-minocycline albumin gel

[0035] 1. Preparation of nano-silver oxide

[0036] Add 0.3688g CTAB solid to a reaction flask containing 10mL each of 0.04mol / L NaOH solution and cyclohexane, stir at room temperature until the solid is completely dissolved, slowly add 0.04mol / L silver nitrate aqueous solution to the solution, stir at 40°C for 1h, and the solution There is dark brown turbidity generated. After the reaction, the product was centrifuged at 4000rpm with a low-speed auto-balancing centrifuge, and the product was washed three times with absolute ethanol and distilled water successively to remove residual ions and CTAB. The washed product was dried in a vacuum oven at 60°C for 1 day to obtain the final nano-silver oxide powder with a particle size of 70-100 nm, uniform particle size distribution and good dispersibility.

[0037] 2. Preparation of Minocycline Buffer

[0038] Put the content of 100mg minocycline hyd...

Embodiment 3

[0046] Embodiment 3: Preparation of nano-titanium oxide-minocycline albumin gel

[0047] 1. Preparation of nano-titanium oxide

[0048] Take 6g of titanium sulfate in a 1000mL volumetric flask, dissolve it with water and dilute to the mark to obtain a 0.05mol / L titanium sulfate solution. Take 1000 mL of 0.05 mol / L titanium sulfate solution and place it in a beaker, add 50 mL of 0.01 mol / L EDTA solution under stirring conditions, and after standing for a period of time, adjust it with sodium hydroxide solution (0.1 mol / L) The pH of the solution was adjusted until a white precipitate appeared. Heat the water bath to 80°C for 2 hours, and wash the precipitate until there is no sulfate ion. The washed product was dried in a vacuum oven at 150°C for 2 hours, and calcined in an infrared oven at 500°C for 2 hours to obtain the final nano-titanium oxide particles with a particle size of 40-100 nm, uniform particle size distribution, and dispersed sex is better.

[0049] 2. Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com