Zinc-doped carbon quantum dot, preparation method thereof and application thereof to detection field

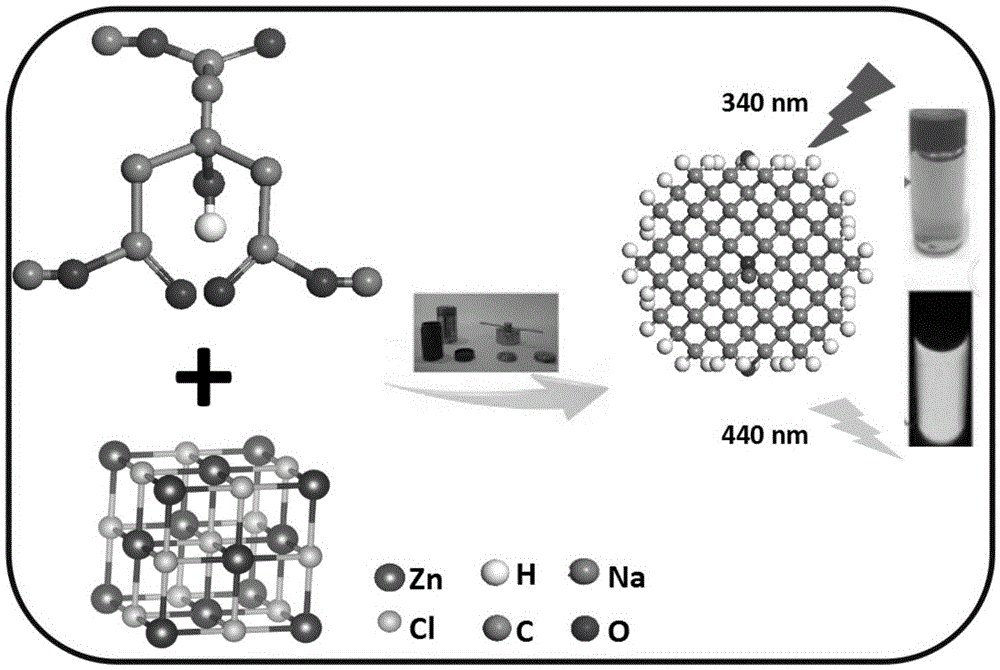

A carbon quantum dot, zinc doping technology, applied in the field of nanomaterials, can solve the problems of low fluorescence quantum yield, damage to the lattice, harm the environment, etc., and achieve the effects of broad application prospects, fast reaction speed, and high luminous intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (a) Take 0.735g of sodium citrate and 0.1704g of zinc chloride, dissolve in 25mL of deionized water, shake well and stir for 5min to obtain a precursor solution;

[0068] (b) Place the obtained precursor solution in a 50ml polytetrafluoroethylene-lined stainless steel autoclave, seal it and react at a temperature of 185°C for 4h, and cool it naturally to room temperature to obtain a suspension;

[0069] (c) Filter the suspension with a cylindrical membrane separation filter with a molecular weight cut-off of 3 kDa, collect the filtrate, and dry to obtain zinc-doped carbon quantum dots with high fluorescence yield. The carbon quantum dots obtained in this embodiment have a luminous intensity of 3.6×10 under the irradiation of 340nm light. 5 , with a quantum yield of 52%.

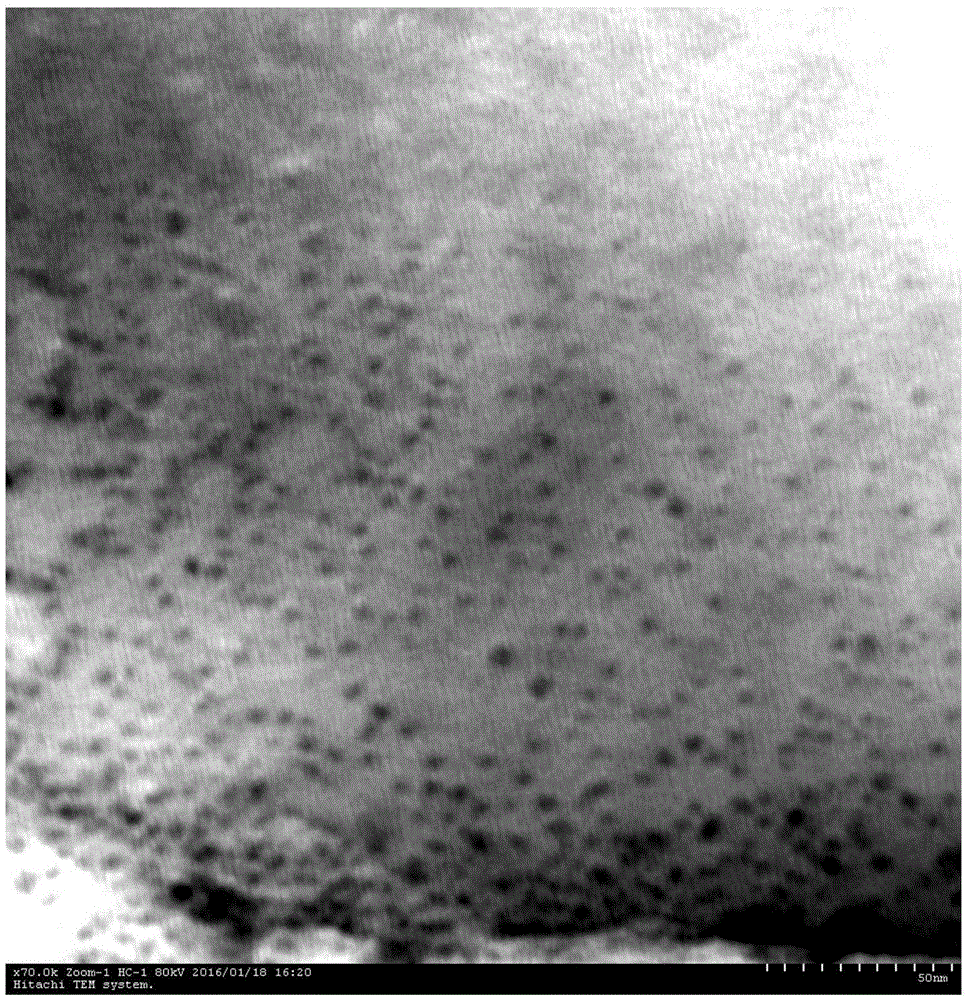

[0070] see figure 1 , which is the transmission electron micrograph of the zinc-doped fluorescent carbon quantum dots prepared in this example, from figure 1 The test shows that the lattice spacing ...

Embodiment 2

[0075] (a) Take 0.735g of sodium citrate and 0.3408g of zinc sulfate, dissolve them in 25mL of deionized water and stir them for 5 minutes to obtain a precursor solution;

[0076] (b) Place the obtained precursor solution in a 50mL polytetrafluoroethylene-lined stainless steel autoclave, seal it and react at 160°C for 4h, and cool it down to room temperature naturally to obtain a suspension;

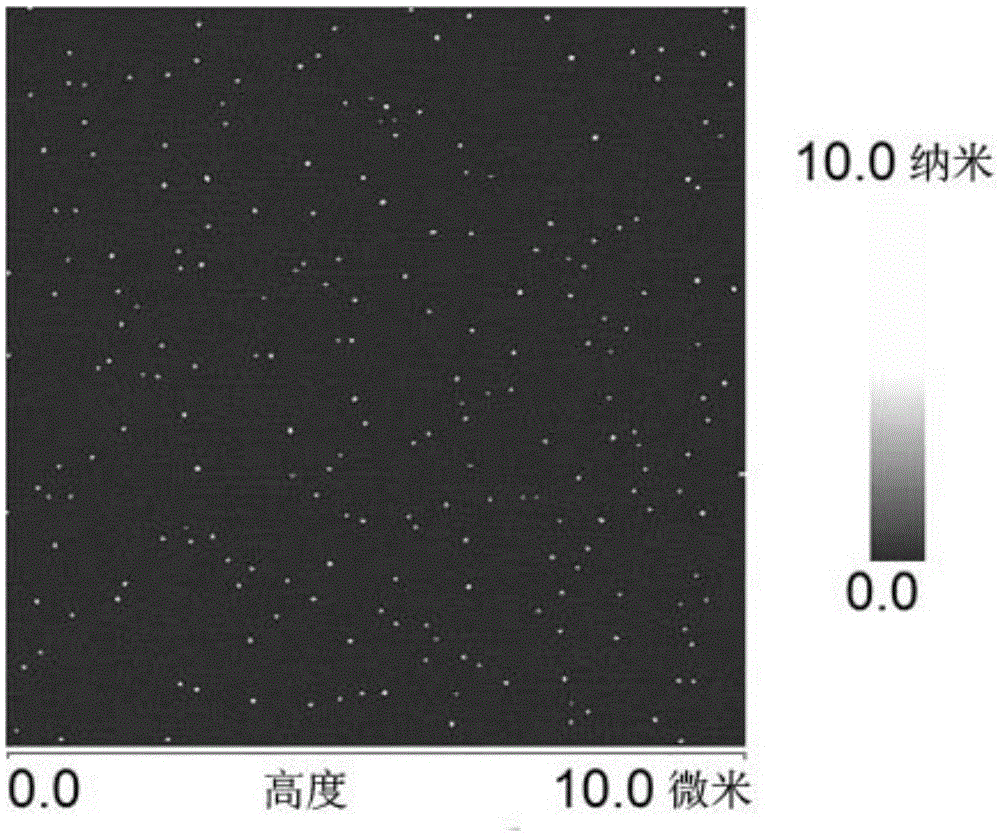

[0077] (c) Filtrating the suspension with a cylindrical membrane separation filter with a molecular weight cut-off of 3 kDa, collecting the filtrate, and drying to obtain zinc-doped carbon quantum dots with a high fluorescence yield. The carbon quantum dots obtained in this embodiment have a luminous intensity of 5.79×10 under the irradiation of 340nm light. 5 , the diameter of carbon quantum dots is 6.78nm, and the quantum yield is 32%.

[0078] see Figure 5-7 It is the XPS peak spectrum of the zinc-doped fluorescent carbon quantum dots prepared in this example. It can be seen from t...

Embodiment 3

[0081](a) Take 0.735g of sodium citrate and 0.1704g of zinc acetate, dissolve them in 25mL of deionized water and stir for 5 minutes to obtain a precursor solution;

[0082] (b) Place the obtained precursor solution in a 50mL polytetrafluoroethylene-lined stainless steel autoclave, react at 190°C under sealed conditions for 4h, and naturally cool to room temperature to obtain a suspension;

[0083] (c) Filtrating the suspension with a cylindrical membrane separation filter with a molecular weight cut-off of 5 kDa, collecting the filtrate, and drying to obtain a zinc-doped carbon quantum dot with a high fluorescence yield. The carbon quantum dots obtained in this embodiment have a luminous intensity of 2.6×10 under the irradiation of 340nm light. 5 , the diameter of carbon quantum dots is 6.34nm, and the quantum yield is 60%.

[0084] see Figure 9 , which is the change curve obtained from the photoluminescence intensity of zinc-doped fluorescent carbon quantum dots prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com