Biological absorbent used for treating heavy metal wastewater and application of biological absorbent

A biosorbent and heavy metal technology, applied in the direction of microorganism-based methods, microorganisms, biological water/sewage treatment, etc., can solve the problems of different adsorption effects of metal ions, high production cost of biosorbents, complicated preparation process, etc., to achieve Enhanced adsorption of heavy metal ions, uniform spherical size, and high chitin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

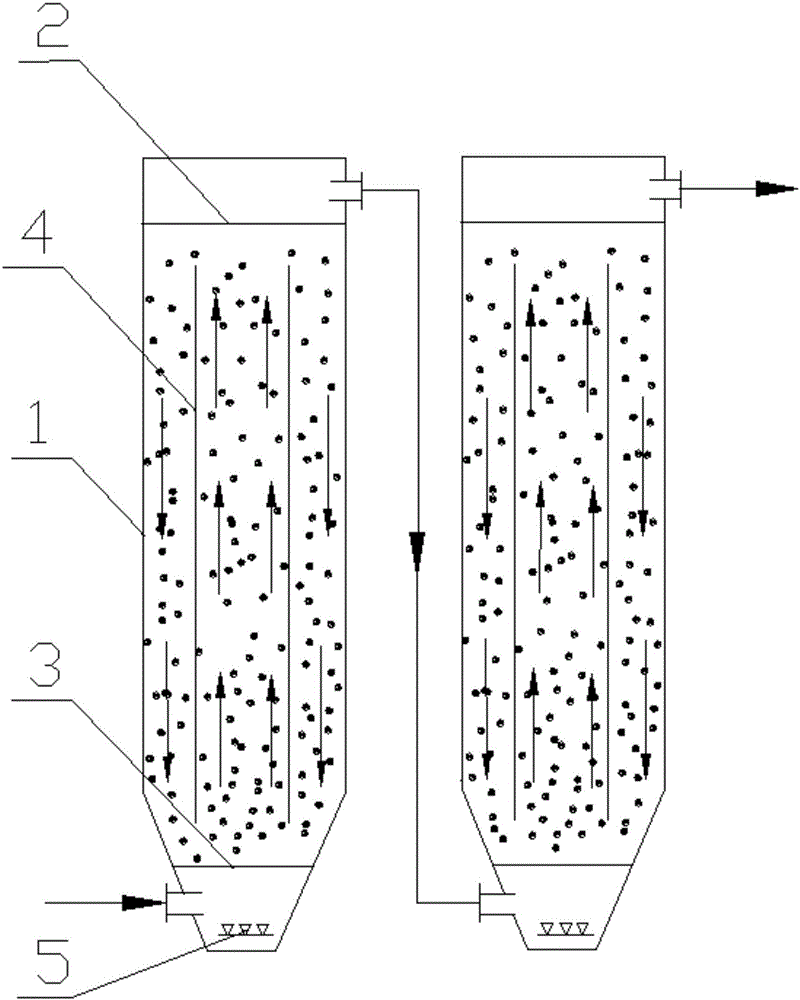

Image

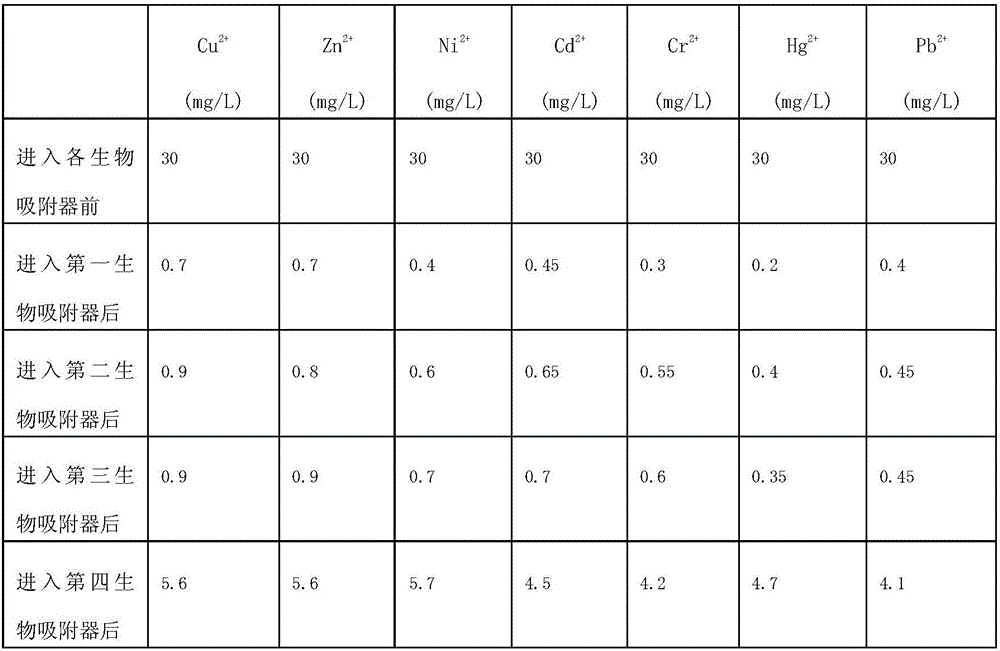

Examples

Embodiment 1

[0021] A biosorbent for treating heavy metal wastewater is prepared by the following method:

[0022] 1) Preparation of corn flour hydrolyzate: A) pulverizing commercially available corn flour to obtain micro corn flour with an average particle diameter of 800 microns; B) mixing micro corn flour and water into a paste at a ratio of 180%, Heat to 40-70°C, add amylase and plant protease, the amylase enzyme amount is 1300U / g micro corn flour, the amount of plant protease is 0.15wt% of micro corn flour, and then pass through 800-1000 mesh screen while it is hot Filtrate to obtain a uniform filtrate, add water to adjust the sugar content after the filtrate is cooled, and make a total sugar of 30g / L corn flour hydrolyzate, the gained corn flour hydrolyzate is composed of corn flour hydrolyzate clear liquid and corn flour hydrolysis residue particles, the corn flour The weight ratio of the hydrolyzed clear liquid to the cornflour hydrolyzed granules is 90-95:5-10;

[0023] 2) Prepar...

Embodiment 2

[0025] A method for preparing a biosorbent for treating heavy metal wastewater, which is prepared by the following method:

[0026] 1) Preparation of degerm corn flour hydrolyzate: A) pulverize commercially available degerm corn flour to obtain micro-degerm corn flour with an average particle diameter of 500 microns; B) mix micro-degerm corn flour with water at 150% After mixing into a paste, heat to 40-70°C, add amylase and plant protease, the amount of amylase added is 1200U / g micro-degerminated corn flour, and the amount of plant protease is 0.1wt of micro-degerminated corn flour %, and then filtered through a 800-1000 mesh screen while it was hot to obtain a uniform filtrate. After the filtrate was cooled, water was added to adjust the sugar content to make a total sugar of 30g / L corn flour hydrolyzate. Flour hydrolyzed clear liquid and degerminated corn flour hydrolyzed residue granules, the weight ratio of degermed corn flour hydrolyzed clear liquid to degermed corn flou...

Embodiment 3

[0029] A method for preparing a biosorbent for treating heavy metal wastewater, which is prepared by the following method:

[0030]1) Preparation of cassava flour hydrolyzate: A) commercially available cassava flour is pulverized to obtain micro-cassava flour with an average particle diameter of 1000; 40-70 DEG C, add amylase and plant protease, amylase added enzyme amount is 1500U / g micro-tapioca flour, the consumption of plant protease is 0.2wt% of micro-tapioca flour, then pass through 800-1000 mesh screen filter while hot, Obtain uniform filtrate, add water to adjust sugar content after filtrate cooling, make total sugar be 30g / L cassava flour hydrolyzate, gained cassava flour hydrolyzate is made up of cassava flour hydrolyzed clear liquid and corn flour hydrolyzed residue particles, described cassava flour hydrolyzed clear liquid The weight ratio of liquid to cassava flour hydrolyzed particles is 90-95:5-10;

[0031] 2) Preparation of Rhizopus oryzae mycelium balls: take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com