Nano-pore sensing device based on two-dimensional layer materials and configuring method thereof

A nanopore sensor, two-dimensional layered technology, applied in the direction of analytical materials, biochemical equipment and methods, specific-purpose bioreactors/fermenters, etc., can solve the problems of low sequence accuracy, high speed, and large pore thickness and other issues, to achieve the effects of solid-state nanopore stability, improved precision, easy design and array processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

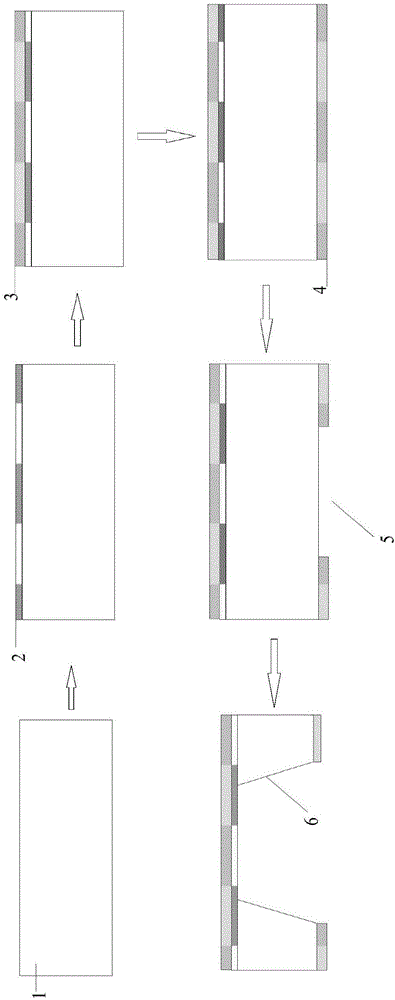

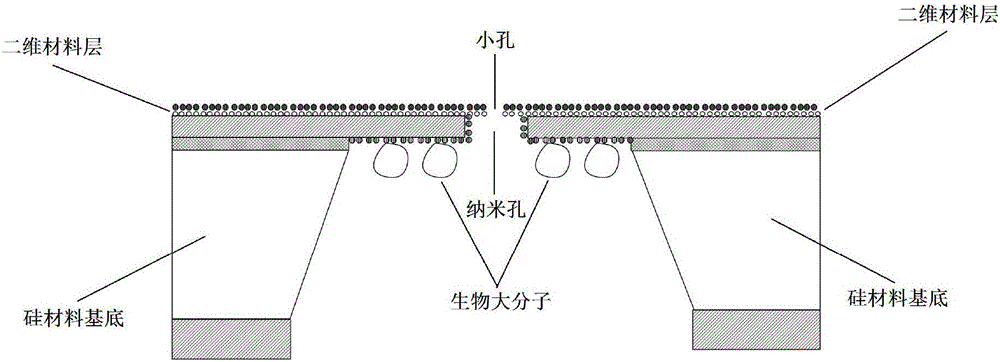

[0038] The preparation of the nanopore sensing device based on the two-dimensional layered material of the present invention specifically includes the following steps:

[0039] 1. Preparation of silicon nitride nanopores based on semiconductor Si material:

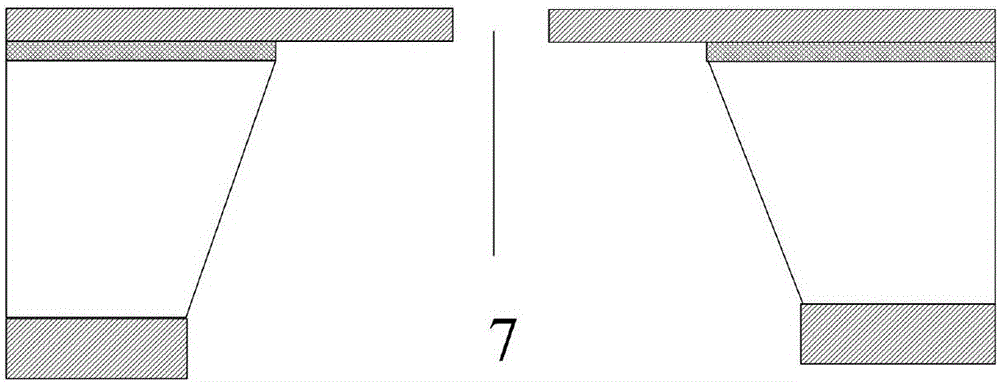

[0040] Such as Figure 2 to Figure 7 As shown, the double-sided polished 4-inch silicon wafer 1 is first cleaned with a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 10-15 minutes, and then cleaned with BOE to remove silicon dioxide formed by natural oxidation on the surface of the silicon wafer. A layer of nanometer-thick silicon dioxide film 2 is formed by sputtering or thermal oxidation growth, and a layer 10 is deposited on the silicon dioxide film by Low Pressure Chemical Vapor Deposition (LPCVD) or plasma enhanced chemical deposition (PECVD). -100nm silicon nitride 3, defining this side as the front side. On the other side of the silicon wafer, a layer of silicon nitride 4 of several hundre...

Embodiment 2

[0050] Implementation steps:

[0051] 1. Select a 4-inch polysilicon wafer, and prepare a low-stress self-supporting silicon nitride film with a thickness of 30nm through silicon technology. Through focused ion beam (FIB) etching (15 seconds), or transmission electron microscope (TEM) etching (180-200 seconds), the density is 920 / μm 2 , a solid-state nanohole array with an average pore diameter of 30nm and laser-cut into a square nanohole chip with a side length of 5mm;

[0052] 2. A square nanohole chip with a side length of 5mm is used to grow two layers of graphene film on a clean silicon wafer by chemical vapor deposition (CVD); a transmission electron microscope (TEM) is used to etch a nanohole with a diameter of 2nm;

[0053] 3. Immerse the silicon nitride nanopore chip containing solid nanopores in a mixture containing 98% concentrated sulfuric acid and hydrogen peroxide solution (volume ratio 7:3) and heat to 95°C, hydrate for 30 minutes, so that the surface has a lar...

Embodiment 3

[0061] Implementation steps:

[0062] 1. The preparation of nanoporous base material is the same as embodiment 1;

[0063] 2. Two layers of molybdenum disulfide were grown on a clean silicon wafer with a square nanohole chip with a side length of 5 mm by chemical vapor deposition (CVD); nanoholes with a diameter of 5 nm were etched using a transmission electron microscope (TEM);

[0064] 3. Treat the nanopore array with oxygen plasma (power 100W) for 2 minutes, and ammonia plasma (power 100W) for 3 minutes to make the surface of the array carry active amino groups;

[0065] 4. Modification of glutaraldehyde as an arm molecule on the nanopore. Under the condition of weak alkaline (pH8-8.5), the aldehyde group at one end of glutaraldehyde is connected to the amino group on the wall of the nanopore to form a Schiff's base, which is then reduced by sodium borocyanide to form a stable amide bond;

[0066] 5. Use 1 μg / mL RNase antibody (anti-RNaseA) aqueous solution (containing 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com