BNT-monocrystal-nanowire-based dielectric composite material and preparation method thereof

A technology of single crystal nano and composite materials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. , limit the thermal conductivity of the compound and other issues, and achieve the effects of less defects, high energy density, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

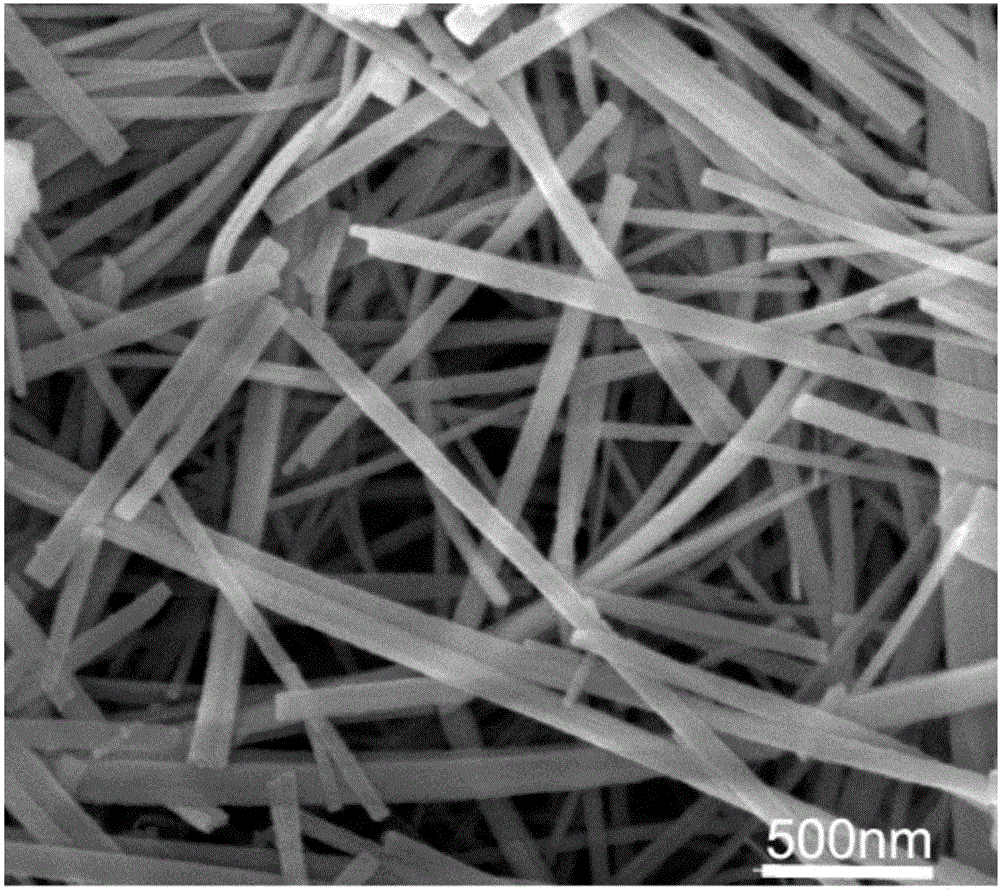

[0037] Hydrothermal Synthesis of BNT Single Crystal Nanowires

[0038] 0.005mol Bi(NO 3 ) 3 ·5H 2 O and 0.01mol NaNO 3 respectively dissolved in 7.5ml CH 3 COOH and 2.5ml deionized water, 0.005mol Ti(OC 4 h 9 ) 4 Dissolve in 10ml CH 3 CH 2 OH, the Bi(NO 3 ) 3 ·5H 2 O solution and NaNO 3 Solution added Ti(OC 4 h 9 ) 4 solution to make a mixed solution. 30ml of 10mol / L NaOH solution was added to the above mixed solution, and magnetically stirred at room temperature for 1h to obtain a uniform precursor solution. Put the precursor solution into a 100ml polytetrafluoroethylene-lined stainless steel reactor, seal it, put it in an incubator at 170°C for 48 hours, and use the pressure spontaneously formed in the reactor to promote the reaction. After the holding time is over, cool down to room temperature naturally. The obtained product was suction-filtered and washed with deionized water, and then dried in a drying oven at 80° C. to obtain BNT single crystal nanowir...

Embodiment 2

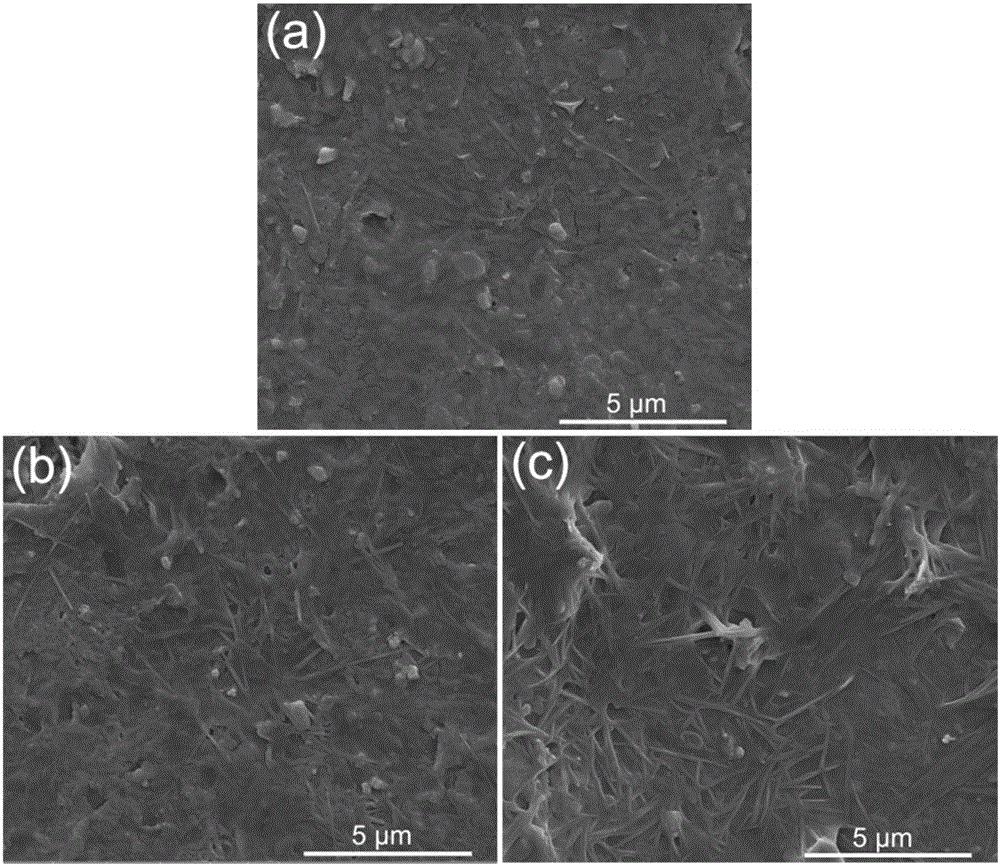

[0040] Preparation of dopamine-modified BNT single crystal nanowires and P(VDF-HFP) dielectric composites

[0041]Weigh 2.0 g of the prepared BNT nanowires and disperse them into a 95:5 (v / v) ethanol / water mixed solution, stir and sonicate, collect the precipitate by centrifugation, and vacuum dry to obtain BNT single crystal nanowires with increased surface hydroxyl content. Disperse the hydroxylated BNT single crystal nanowires in 0.01mol / L dopamine hydrochloride aqueous solution, reflux at 60°C for 10h, cool to room temperature, centrifuge, and thoroughly wash with deionized water, collect the powder in a vacuum drying oven for 60 ℃ dry 24h.

[0042] Add 2.37vol%, 5.19vol% and 12.73vol% dopamine-modified BNT single crystal nanowires to the P(VDF-HFP) polymer solution, after ultrasonic dispersion, ball milling for 2 days to further disperse, the dispersed BNT / P The (VDF-HFP) suspension was tape-cast on a clean glass sheet, dried at 80°C for 24 hours to obtain a composite sh...

Embodiment 3

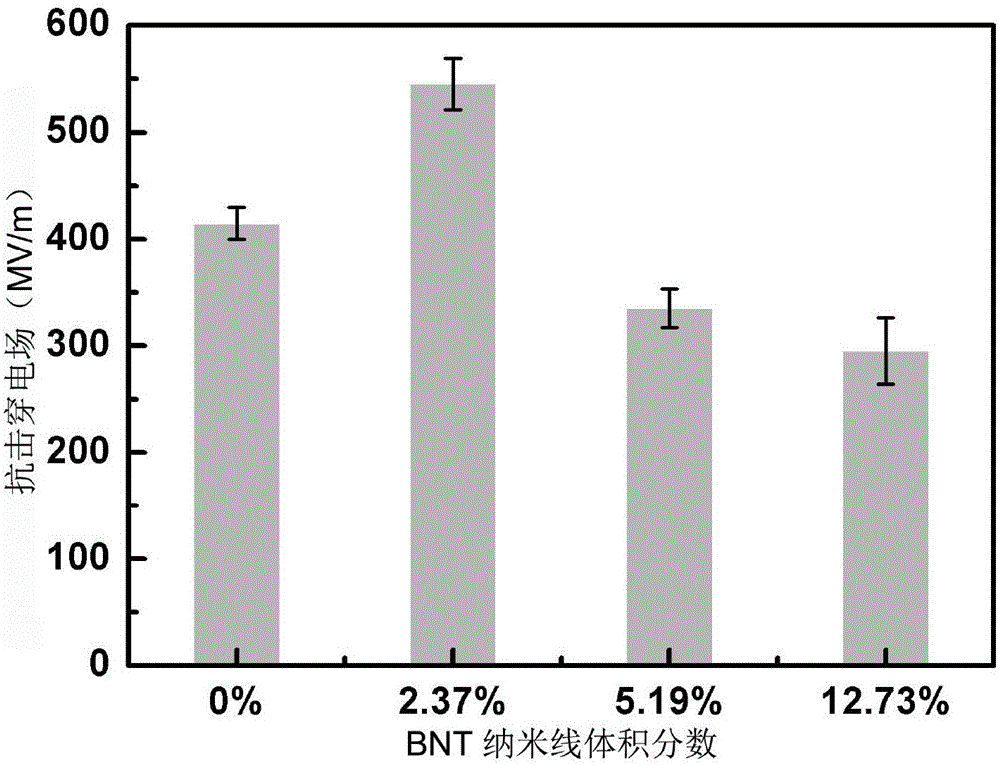

[0044] Electrical Performance Testing of Dielectric Composite Materials

[0045] Design a metal mask with a circular hole diameter of 2 mm and a hole center spacing of 4 mm. The shape of the metal mask is square with a side length of 30 mm. The pressed dielectric composite material is sandwiched between two metal masks, and the gold electrodes are symmetrically sputtered on the upper and lower surfaces, and the sputtering time is 10 minutes on the upper and lower surfaces to ensure that the gold electrodes have sufficient thickness. Using an impedance analyzer to test its capacitance to obtain the dielectric constant, the results are as follows Figure 4 As shown, it can be seen that the dielectric constant of the composite increases with the increase of BNT nanowire content, such as at 1kHz, when the BNT nanowire content in the composite is 0, 2.37, 5.19 and 12.73vol%, respectively The dielectric constants are 6.9, 13.1, 16.9 and 21.7, respectively. Use a ferroelectric anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com