A kind of molecular cluster material of supramolecular polymer and its preparation method and application

A supramolecular polymer, molecular cluster technology, applied in chemical instruments and methods, descaling and water softening, special treatment targets, etc., can solve the problems of small exchange capacity, difficult automatic regeneration, short life, etc. , the effect of a wide range of use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

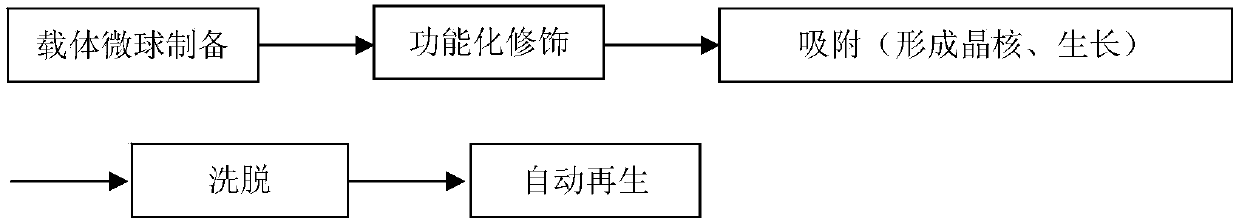

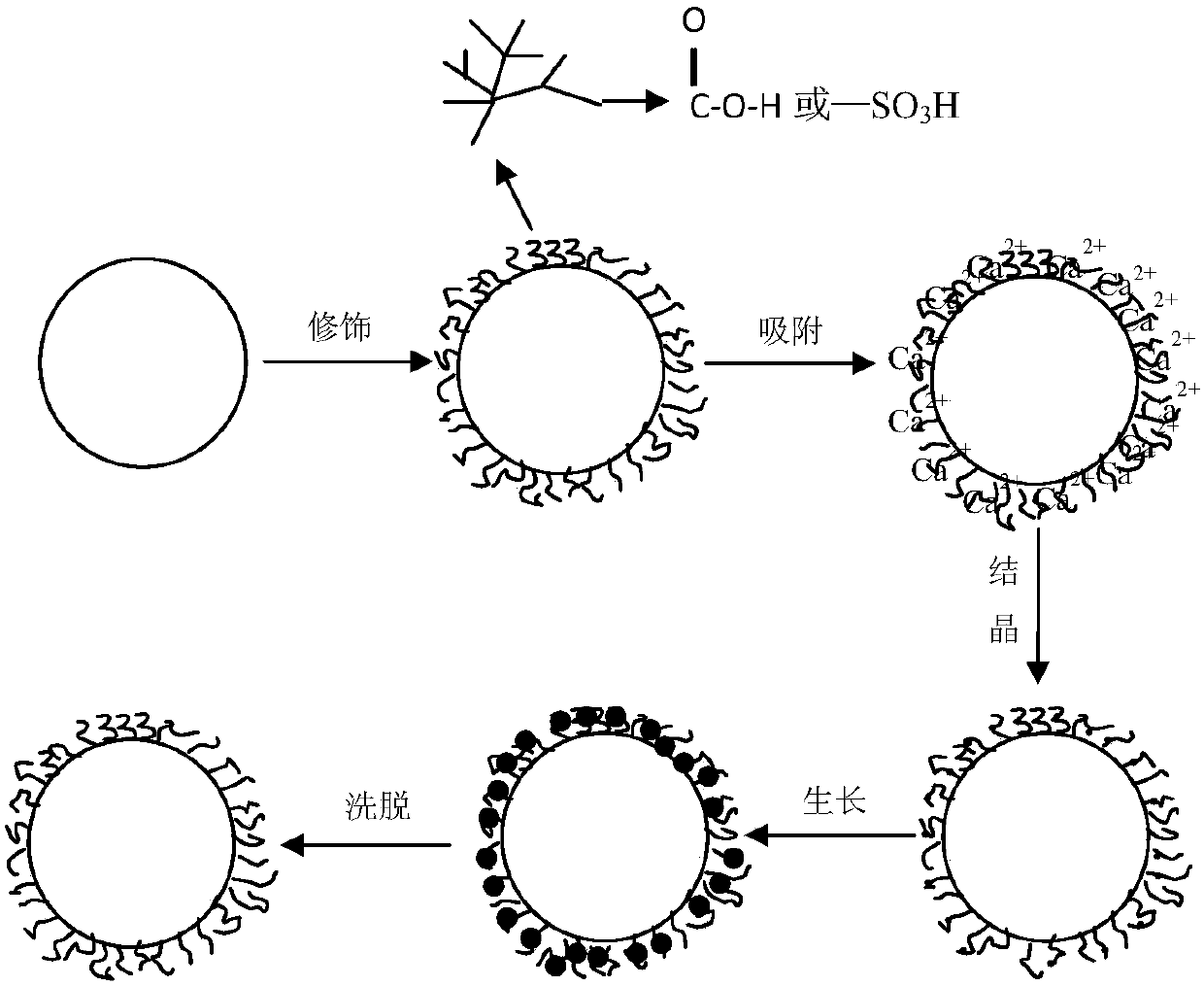

Method used

Image

Examples

Embodiment 1

[0034] Take 40mL of styrene monomer, 1.68g of polyvinylpyrrolidone as a dispersant, 0.42g of azobisisobutyronitrile as a free radical initiator, 180mL of absolute ethanol, 20mL of deionized water, and stir at a speed of 300-500r / min. Reacted at 70°C for 8h under nitrogen. After the reaction, the product was centrifuged / washed with ethanol (three cycles), and vacuum-dried at 60° C. for 24 hours to obtain molecular cluster substrate PS microspheres.

[0035]Take the base PS microspheres as seeds, add them to 0.25% SDS aqueous emulsion, add 0.6% to 0.7% swelling agent dichloromethane or 1,2-dichloroethane, and disperse them in the solution by ultrasonic emulsification, Swell at 30°C for 10h, and the stirring speed is about 100r / min. Then add 0.1%-0.3% initiator potassium persulfate (KPS) and 0.5-1.5% cross-linking agent ethylene glycol dimethacrylate, add 40%-50% functional monomer acrylic acid (AA), Disperse by ultrasonic emulsification and continue swelling at 30°C for 12h. ...

Embodiment 2

[0037] Prepare PS microspheres according to the steps in Example 1, add the dry PS microspheres to the mixed solution composed of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 2:3, and stir and react at 40°C at 400r / min for 2-3h. The product was filtered, centrifuged, and dried at 50°C for 24 hours to obtain light yellow nitropolystyrene microspheres (PS-NO 2 ). Then add 30mL 0.2mol / L NaOH aqueous solution and 2g Na 2 S 2 o 4 , stirred at 400r / min at 75°C for 4h, centrifuged and washed with deionized water several times to obtain aminopolystyrene microspheres.

[0038] Weigh 0.5g of amino polystyrene microspheres into a three-necked flask, add 10mL of ethanol, ultrasonically disperse, then add 12mL of ethanol solution containing 15% to 25% polyacrylic acid (PAA), stir and reflux at 70°C under nitrogen for 12h . The reaction product was washed to neutral with deionized water, and dried to obtain PS-PAA molecular clusters. Such as image 3...

Embodiment 3

[0040] Prepare PS microspheres according to the steps in Example 1, add 15% to 20% of dry PS microspheres to glycidol, add toluene to immerse, add pyridine, and stir at 260r / min at 80-95°C under nitrogen protection Reaction 24h. After the reaction, the product was repeatedly washed with deionized water and dried to obtain polystyrene glycidyl microspheres.

[0041] Take 2.0g of dry polystyrene glycidol microspheres and disperse them in 80-90mL of concentrated sulfuric acid, and sulfonate them at 40°C at 200-300r / min for 10h. After the reaction, the reactant was taken out by centrifugation, washed repeatedly with ethanol, and dried to obtain sulfonated polystyrene glycidyl microsphere clusters (PS-PG-SO 3 H molecular cluster). Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com