Composite ball containing self-assembly microcapsule and preparation method thereof

A technology of microcapsules and self-assembly, which is applied in the direction of microsphere preparation and microcapsule preparation, etc. It can solve the problems of complex preparation process, self-polymer impurities, low capsule purity, etc., and achieve high encapsulation efficiency, little influence on pH value, well-formed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

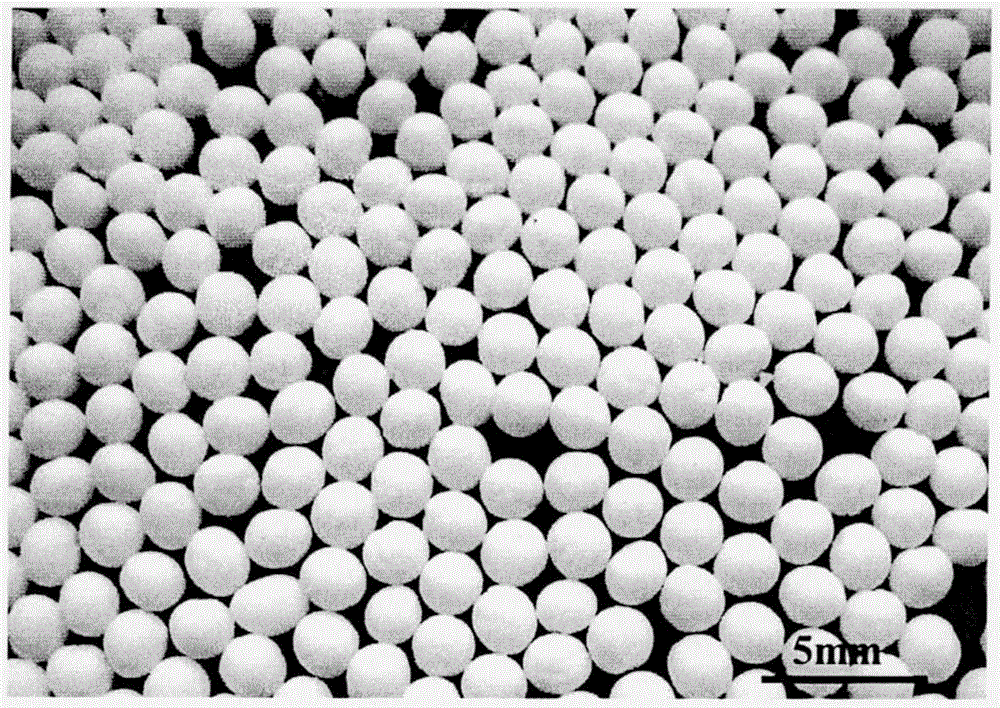

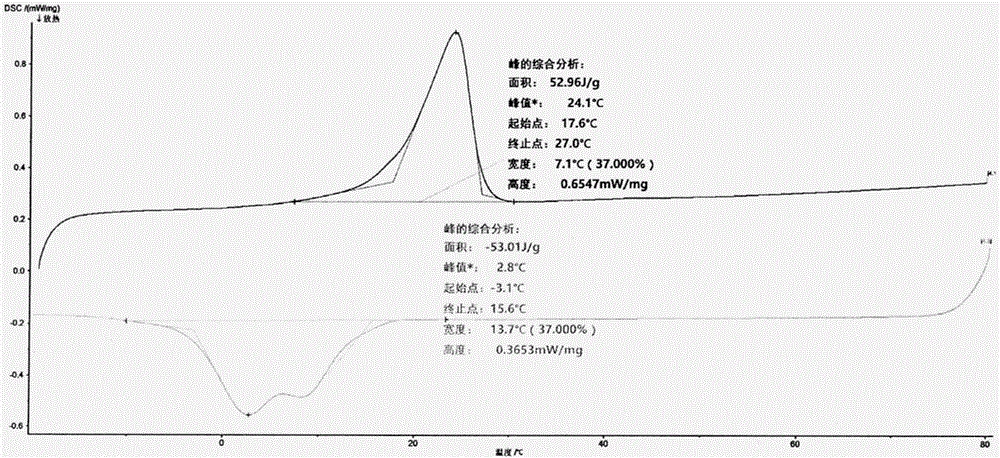

Embodiment 1

[0028] Stir 10g of n-dodecyl alcohol and 10g of n-butyl etherified amino resin evenly to obtain an oil phase solution; add this oil phase solution to 150g of SMA aqueous solution with a concentration of 2wt%, and then emulsify at a high speed at 5000rpm for 5min to obtain Stable oil-in-water emulsion; 75g of 5wt% sodium alginate is added as a matrix and stirred to increase the dispersion of the emulsion, using an electrospinning nozzle (coaxial composite nozzle (inner diameter 0.6mm outer diameter 1.5mm) ) is sprayed into a low-concentration calcium chloride solution, the Ca in the calcium chloride solution 2+ It will complex with carboxylate ions in sodium alginate to form a gel of calcium alginate; in this process, use 20wt% citric acid solution to adjust the pH value to 1-2; mix the above-mentioned calcium chloride with the spherical product Transfer to a three-necked flask, heat up to 90°C while stirring at a speed of 400rpm, adjust the pH value to about 7 with 20wt% sodiu...

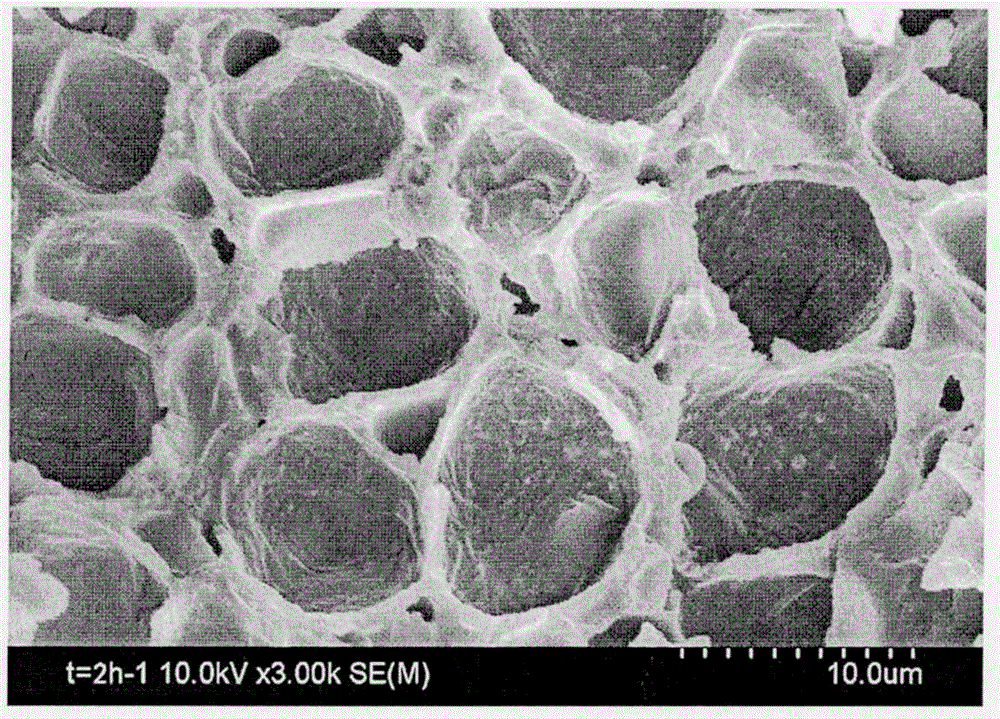

Embodiment 2

[0031] Stir 1kg of coconut essence and 500g of methyl etherified amino resin evenly to obtain an oil phase solution; add this oil phase solution to 2kg of emulsifier OP-10 aqueous solution with a concentration of 5wt%, and then emulsify at a high speed of 5,000rpm for 20 minutes , to produce a stable oil-in-water emulsion. Add 1kg of 5% polymaleic anhydride as a matrix and fully stir it, and spray it into the manganese chloride solution at low concentration under different jets, airflows, concentrations, and thrusts by using an electrospinning nozzle; the composite ball Pour the mixed liquid with polymaleic anhydride into the three-port burnt product, and heat up to 90°C while stirring at a speed of 400rpm. During this process, use 20% citric acid solution to adjust the pH value to about 2. After reacting for 3 hours, filter and wash , drying to get amino resin composite balls. Observing the sample with a scanning electron microscope, the microcapsule particle size distributi...

Embodiment 3

[0034]Mix 2kg of mosquito repellent incense oil, 1kg of n-octyl etherified amino resin and 100g of acetone to obtain an oil phase solution; add this oil phase solution to the emulsifier aqueous solution prepared by dissolving 1kg of polyvinylpyrrolidone in 10kg of water , high-speed emulsification at 2000rpm for 30 minutes to obtain an oil-in-water emulsion with an average particle size of 20 μm; 10kg of 5% polyvinyl alcohol was added as a matrix and fully stirred. Spray it into a calcium nitrate solution at a low concentration under low concentration, concentration, and thrust, add citric acid dropwise to adjust the pH value to 3, then raise the temperature to 85°C, and react for 2 hours to obtain an amino resin composite ball of mosquito repellent fragrance. The morphology and structure of the samples were observed with a scanning electron microscope, and most of the particle sizes of the microcapsules inside the spherical capsules were distributed in the range of 5-100 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com