Thioether oxidation method

A technology of thioether oxidation and thioether, which is applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of limited thioether dissolution, cost burden, and low thioether conversion rate, and achieve an increase in processing capacity and Operational efficiency, reduced operating costs, and the effect of high sulfide conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5-14、18、19、21 and 24-31

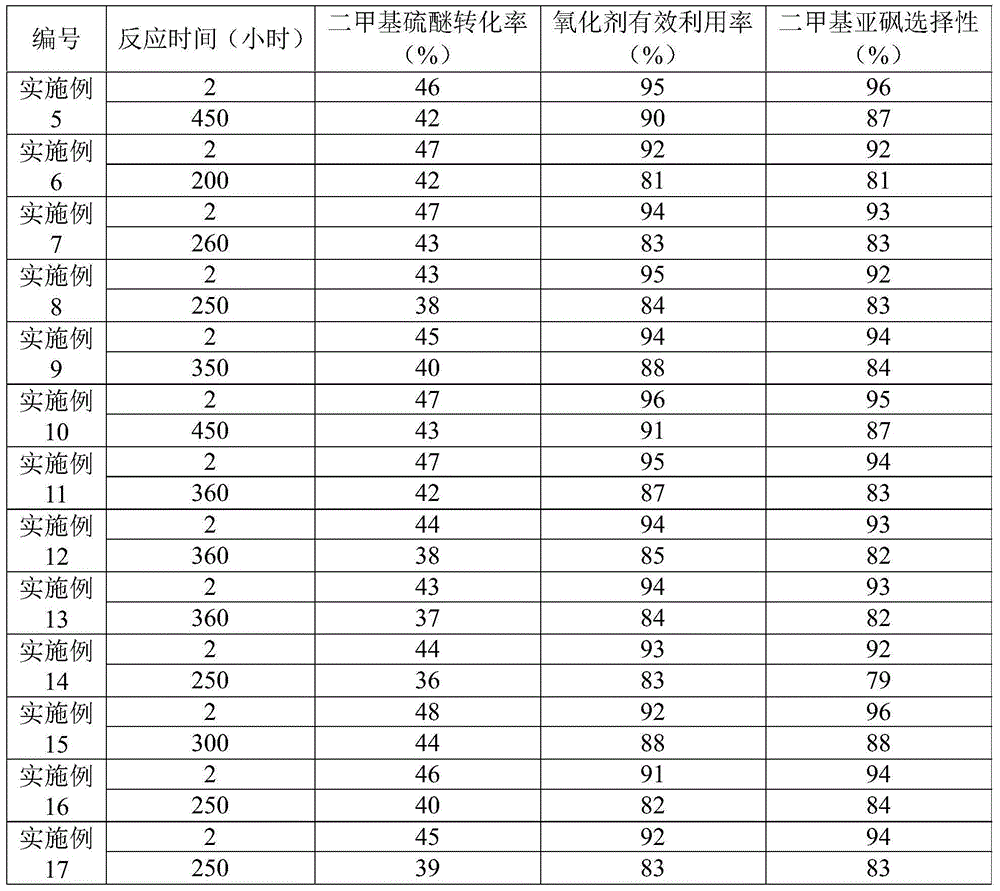

[0064] Embodiment 5-14, 18, 19, 21 and 24-31 adopt the following method to measure the activity of catalyst:

[0065] Catalyst, 36% by weight of ammonia (as NH 3 meter), 30% by weight of hydrogen peroxide (as H 2 o 2 ), tert-butanol and cyclohexanone by mass ratio = 1:7.5:10:7.5:10 and then stirred and reacted at 80°C under atmospheric pressure for 2h, filtered the reactant, and analyzed the obtained liquid phase by gas chromatography The composition of the catalyst is analyzed, and the conversion rate of cyclohexanone is calculated by the following formula and used as the activity of the catalyst,

[0066] The conversion rate (%) of cyclohexanone=[(the molar amount of cyclohexanone added−the molar amount of unreacted cyclohexanone) / the molar amount of cyclohexanone added]×100%.

[0067] In Examples 23 and 29, the pore volume and ultraviolet absorption peak of the titanium-silicon molecular sieve before and after modification were characterized by static nitrogen adsorption...

Embodiment 1

[0070] (1-1) Isopropanol and oxygen (provided in the form of a mixed gas of oxygen and nitrogen, based on the total amount of the mixed gas, the content of oxygen is 85% by volume) at a temperature of 120 ° C and a pressure of 1.5 MPa Under the conditions of contact reaction for 6 hours, a liquid mixture containing hydrogen peroxide and acetone was obtained, wherein the molar ratio of isopropanol to oxygen was 1:10. The composition of the liquid mixture was analyzed by gas chromatography, and it was determined that the total content of hydrogen peroxide and acetone was 28% by weight, and the molar ratio of hydrogen peroxide and acetone was 1:1.

[0071] (2) The liquid mixture obtained in step (1-1), dimethyl sulfide and titanium silicon molecular sieve TS-1 are placed in a high-pressure reactor for stirring reaction. Wherein, the mass ratio of dimethyl sulfide and titanium silicon molecular sieve TS-1 is 20:1, and the molar ratio of hydrogen peroxide and dimethyl sulfide in th...

Embodiment 2

[0073] The same method as in Example 1 is used to oxidize dimethyl sulfide, the difference is that step (1-2) is also carried out: the liquid mixture obtained in step (1-1) is mixed with hydrochloric acid (HCl concentration is 36.5% by weight) Mix in an autoclave, wherein the molar ratio of hydrogen peroxide to HCl in the liquid mixture obtained in step (1-1) is 1:0.005, the temperature in the autoclave is controlled at 40°C, and the The pressure is controlled as normal pressure (that is, 1 standard atmospheric pressure), and the mixing time is 2 hours to obtain the acid-treated liquid mixture, and the acid-treated liquid mixture obtained in step (1-2) is sent into step (2).

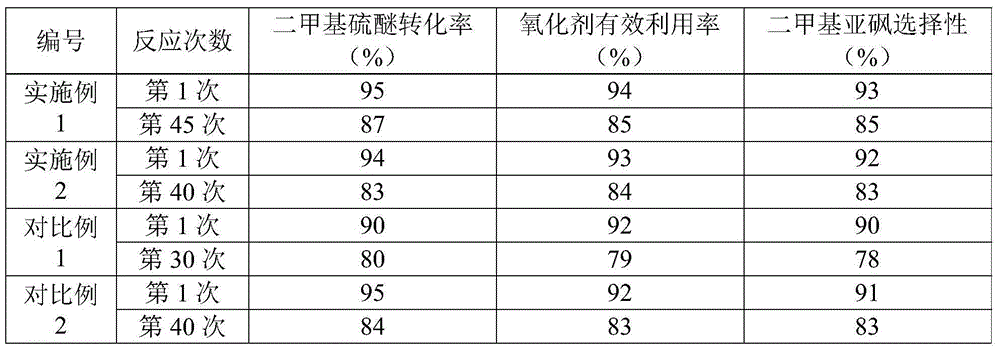

[0074]Table 1 lists the reaction results of titanium silicate molecular sieve TS-1 when it is used for the first time and for the 40th time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com