Preparation method of SiO2 aerogel

A silicon dioxide and aerogel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of reducing the production cost of aerogel, insufficient comprehensive utilization ability of fly ash acid residue, etc., and achieve low density and environmental impact. Small, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation embodiment of fly ash acid slag

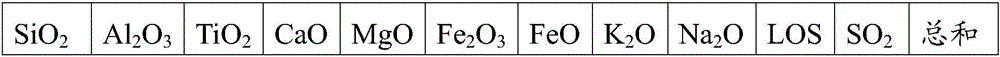

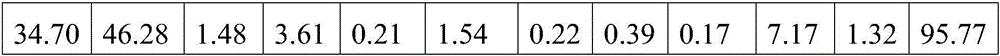

[0038] The raw material is circulating fluidized bed pulverized coal produced by a thermal power plant, and its chemical composition is shown in Table 1.

[0039] Table 1 CFB fly ash chemical composition (wt%)

[0040]

[0041]

[0042] Get the fluidized bed fly ash, pulverize to 200 orders, add water and make the slurry that solid content is 33wt%, use vertical ring magnetic separator (referring to Chinese patent CN102145905A, and its whole content is introduced into this paper), at field strength of Magnetic separation under 15,000 GS twice, obtain the filter cake that solid content is 37.5wt% after the press filtration of plate and frame filter press; In described filter cake, add the industrial hydrochloric acid that concentration is 28wt% to carry out acid dissolution reaction, in hydrochloric acid The molar ratio of HCl to alumina in fly ash is 5:1, the reaction temperature is 150°C, the reaction pressure is...

Embodiment 1

[0050] Mix 1kg of residue with 5L of sodium hydroxide (mass fraction is 15%) solution, place in a reaction kettle, set the reaction temperature to 90°C, and the reaction time to be 120min; obtain the filtrate after filtration, pass the filtrate through strong acid benzene Ethylene cation exchange resin to obtain silicic acid with a pH value of 2 to 3, then dissolve P123 in ethanol solution, and then slowly add P123 solution to the silicic acid solution under stirring conditions, the mass ratio of silicic acid to P123 is 1.3, stir for 3 hours, use 1mol / l ammonia solution to adjust the pH of the solution to 5, stir for 1min, and after the reaction is over, let the reactants stand still to produce SiO 2 Hydrogel; after the obtained hydrogel is left to stand and aged in water for 24 hours, soak the prepared gel with n-hexane for 24 hours, then move the prepared gel into a drying oven, keep the temperature at 70°C for 4 hours, and then put the prepared gel Place in ethanol solution...

Embodiment 2

[0053] Mix 1kg of residue with 5L of sodium hydroxide (mass fraction is 15%) solution, place in a reaction kettle, set the reaction temperature to 90°C, and the reaction time to be 120min; obtain the filtrate after filtration, pass the filtrate through strong acid benzene Ethylene cation exchange resin to obtain silicic acid with a pH value of 2 to 3, then dissolve P123 in a solution of ethanol and hydrochloric acid, and then slowly add P123 solution to the silicic acid solution under stirring conditions, the mixture of silicic acid and P123 The mass ratio is 1.3, stirred for 3 hours, the pH of the solution is adjusted to 5 with 1mol / l ammonia water, stirred for 1 minute, and the hydrosol is obtained after the reaction is completed; the obtained hydrogel is aged for 24 hours to obtain a gel, soaked in n-hexane Prepare the gel for 24 hours, then move the prepared gel to a drying oven, keep the temperature at 70°C for 4h, then place the prepared gel in an ethanol solution acidifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com