Formula and preparation method of heavy metal sewage treatment agent

A sewage treatment agent and heavy metal technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low treatment efficiency, complicated preparation methods, and complicated treatment processes, and achieve sewage treatment Simple processing method, simple preparation method, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

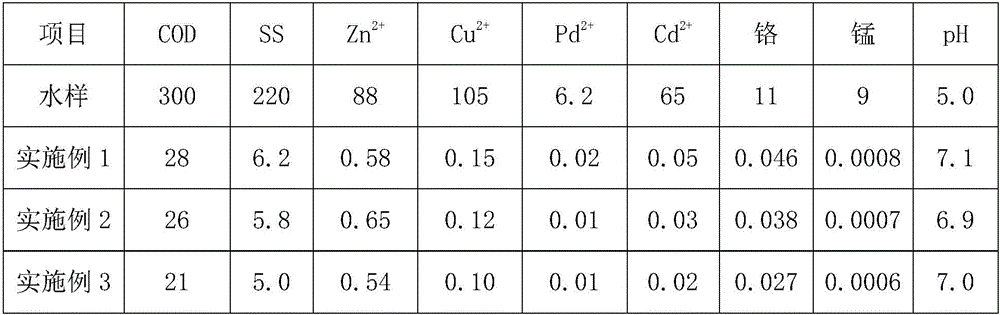

Examples

Embodiment 1

[0021] A heavy metal sewage treatment agent formula, comprising the following raw materials in parts by weight: 20 parts of corn stalks, 10 parts of polysilicoaluminum sulfate, 15 parts of polyacrylamide, 10 parts of activated carbon, 2 parts of diatomite, 5 parts of fly ash, 6 parts of sodium bicarbonate, 5 parts of sodium silicate, 0.1 part of cobalt oxide, 10 parts of anhydrous magnesium sulfate, 5 parts of chitosan, 1 part of magnetic fluid, 5 parts of ferrocene, 5 parts of lecithin, 1 part of cobalt phthalocyanine 5 parts, 5 parts of hemp fiber, 8 parts of sodium monofluorophosphate.

[0022] A preparation method of a natural mineral heavy metal sewage treatment agent, the specific steps are:

[0023] (1) Weigh corn stalks, polysilicon aluminum sulfate, polyacrylamide, activated carbon, diatomaceous earth, fly ash, sodium bicarbonate, sodium silicate, cobalt oxide, anhydrous magnesium sulfate, chitosan according to parts by weight , ferrocene, lecithin, cobalt phthalocya...

Embodiment 2

[0029] A heavy metal sewage treatment agent formula, comprising the following raw materials in parts by weight: 30 parts of corn stalks, 20 parts of polysilicoaluminum sulfate, 20 parts of polyacrylamide, 20 parts of activated carbon, 8 parts of diatomaceous earth, 10 parts of fly ash, 15 parts of sodium bicarbonate, 10 parts of sodium silicate, 1 part of cobalt oxide, 15 parts of anhydrous magnesium sulfate, 8 parts of chitosan, 8 parts of magnetic fluid, 8 parts of ferrocene, 10 parts of lecithin, 10 parts of cobalt phthalocyanine 15 parts, hemp fiber 15 parts, sodium monofluorophosphate 15 parts.

[0030] A preparation method of a natural mineral heavy metal sewage treatment agent, the specific steps are:

[0031] (1) Weigh corn stalks, polysilicon aluminum sulfate, polyacrylamide, activated carbon, diatomaceous earth, fly ash, sodium bicarbonate, sodium silicate, cobalt oxide, anhydrous magnesium sulfate, chitosan according to parts by weight , ferrocene, lecithin, cobalt...

Embodiment 3

[0037] A heavy metal sewage treatment agent formula, comprising the following raw materials in parts by weight: 25 parts of corn stalks, 18 parts of polysilicon aluminum sulfate, 16 parts of polyacrylamide, 15 parts of activated carbon, 6 parts of diatomite, 7 parts of fly ash, 11 parts of sodium bicarbonate, 7 parts of sodium silicate, 0.6 parts of cobalt oxide, 12 parts of anhydrous magnesium sulfate, 6 parts of chitosan, 6 parts of magnetic fluid, 7 parts of ferrocene, 9 parts of lecithin, 8 parts of cobalt phthalocyanine part, 11 parts of hemp fiber, 12 parts of sodium monofluorophosphate; the magnetic fluid is SiO2 / Fe3O4.

[0038] A preparation method of a natural mineral heavy metal sewage treatment agent, the specific steps are:

[0039] (1) Weigh corn stalks, polysilicon aluminum sulfate, polyacrylamide, activated carbon, diatomaceous earth, fly ash, sodium bicarbonate, sodium silicate, cobalt oxide, anhydrous magnesium sulfate, chitosan according to parts by weight ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com