Polyether-ether-ketone material and modification method based on plasma immersion ion implantation and application

A polyetheretherketone and plasma technology, which is applied in the field of biomedical materials, can solve the problems of complicated and tedious operation process, different properties of PEEK, and insufficient bonding, and achieves simple cleaning procedures, improved mechanical properties, and good cell compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

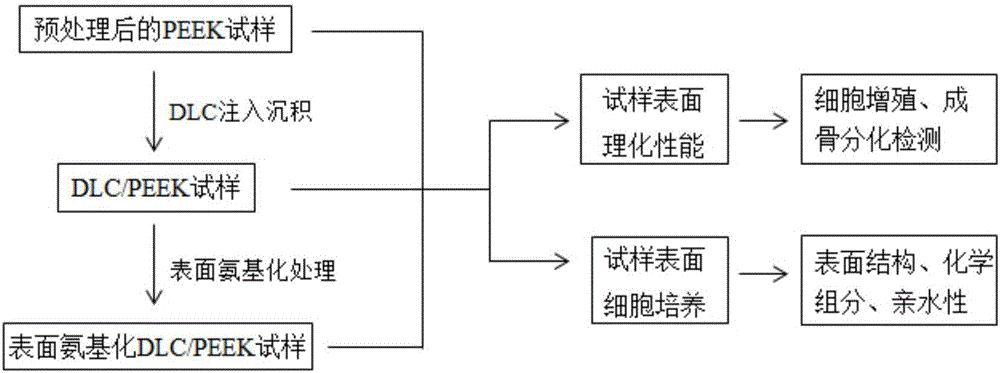

Method used

Image

Examples

Embodiment 1

[0069] The polyether ether ketone disc with a diameter of 15 mm and a height of 2 mm was polished and cleaned with acetone, alcohol, and deionized water by ultrasonic cleaning for 20 minutes each time. After cleaning, it was dried in an oven at 40°C and stored properly. The sample after this pretreatment is called PEEK control.

[0070] Plasma immersion ion implantation technology is used to deposit a diamond-like carbon film on the surface of the preserved polyetheretherketone. The specific process parameters are shown in Table 1. The obtained sample is called DLC / PEEK.

[0071] Table 1 Process parameters of diamond-like carbon film deposition

[0072]

[0073] Note: sccm = standard cubic centimeter per minute

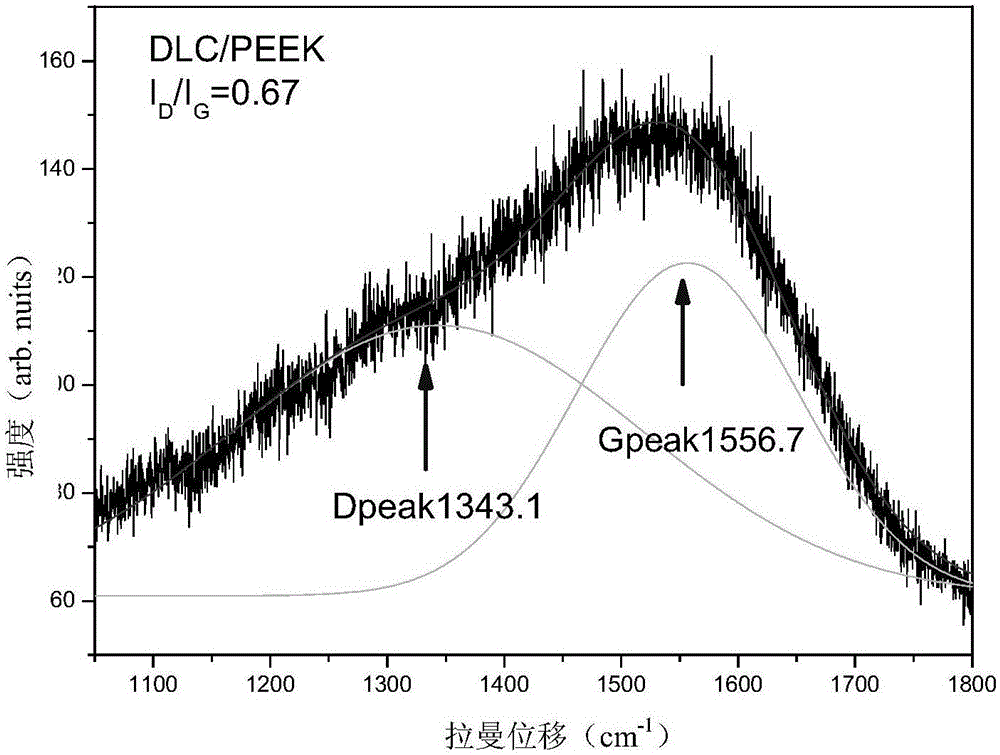

[0074] Raman spectrum analysis of DLC / PEEK surface, using laser Raman spectrometer to measure the Raman spectrum curve of DLC film, the laser wavelength is 514.5nm, and the spectrum measurement range is set to 1000~1800cm -1 , Step length 2cm -1 ,get figure 2 In the Raman sp...

Embodiment 2

[0077] Place the DLC / PEEK sample with a diameter of 15mm and a height of 2mm on a stainless steel circular tray, and then put it in a vacuum chamber to vacuum, and introduce argon for cleaning for 5 minutes to ensure the removal of contaminants and oxides on the sample surface.

[0078] Plasma immersion ion implantation technology is used to inject ammonia into the surface of DLC / PEEK. The specific process parameters are shown in Table 2. The sample obtained is called NH 2 -DLC / PEEK.

[0079] Table 2 DLC / PEEK surface NH 3 -PIII process parameters

[0080]

[0081] Note: sccm = standard cubic centimeter per minute

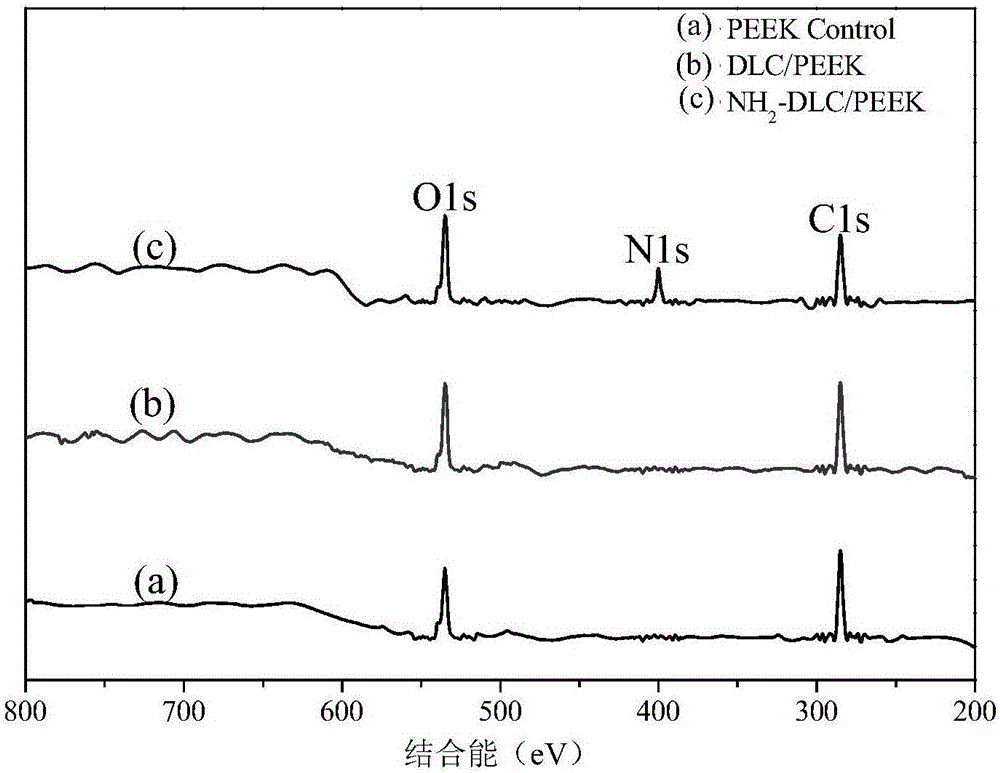

[0082] X-ray photoelectron spectroscopy (XPS) wide-field scanning was performed on the surface of the single modified and double modified polyether ether ketone samples obtained in Examples 1 and 2, and the instrument conditions were as follows: Al Kα excitation source, target voltage and target current, respectively 15kV and 10mA, the vacuum chamber pressure is less than 2...

Embodiment 3

[0085] The nano-scratch technology was used to evaluate the surface mechanical properties of the polyether ether ketone material treated in the above examples 1 and 2. The loading force was 10N. Taking into account the contact area between the spherical ball indenter and the sample surface, the loading pressure was approximately 0.9~1GPa; the sample surface rubs to form a circle with a diameter of 10mm, and the rotation speed is 573r / min. It wears a total of 600s, which is converted into a total stroke length of 180m.

[0086] Figure 4 It represents the relationship between surface friction coefficient and time, the abscissa represents the loading time, and the ordinate represents the corresponding friction coefficient. by Figure 4 It can be seen that the friction coefficient is slowly increasing with time. At the same time, a clear and intuitive scanning electron microscope image of the scratched surface is obtained, namely Figure 5a with Figure 5b . Figure 5a It is the sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com