Method for preparing galacto-mannan-oligosaccharides (GMOS)

A technology of galactomannan and oligosaccharide, which is applied in the field of preparation of galactomannan oligosaccharide, can solve the problems of inability to rapidly swell and hydrate, high viscosity of the reaction system, waste of time and resources, etc., and achieves good particle solubility, The effect of saving enzymatic hydrolysis time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Dissolve 1mmol of ascorbic acid and 30mmol of food-grade hydrogen peroxide in 1L of water, add 200g of guar gum after dissolving evenly, and react in the reactor at 40°C for 15min at a speed of 40-60r / min.

[0018] 2. Add catalase to the reaction solution at 3000 U / L, and react at 40°C for 15 minutes.

[0019] 3. After the reaction, refer to GB-T 23499-2016, and use the titanium salt colorimetric method to determine whether hydrogen peroxide remains in the reaction system.

[0020] 4. Adjust the pH of the reaction solution to 2.5 with hydrochloric acid, add acidic β-mannanase according to the amount of 200 U / g guar gum substrate for enzymolysis, and react at 50°C for 1 hour.

[0021] 5. Boil the enzymatic hydrolysis solution to kill the enzyme, then centrifuge at 4800rpm for 20min to remove the insoluble enzymatic hydrolysis residue.

[0022] 6. Concentrate the supernatant to 400mL by suspension steaming, add 1200mL 95% ethanol according to 3 times the volume of the...

Embodiment 2

[0026] 1. Dissolve 20mmol of ascorbic acid and 1.5mol of food-grade hydrogen peroxide in 50L of water, steam the jacket of the enzymolysis tank to preheat the water in the tank to 45-50°C, add 12.5kg of guar gum, and ferment the tank at 50 Stir the reaction at ℃ for 25min, and the rotation speed is 55-60r / min.

[0027] 2. Add catalase to the reaction solution at 3000U / L, stir and react at 50°C for 15min, and rotate at a speed of 55-60r / min.

[0028] 3. After the reaction is over, refer to GB-T 23499-2016, and use the titanium salt colorimetric method to determine whether hydrogen peroxide remains in the reaction system.

[0029] 4. Adjust the pH of the reaction solution to 2.5 with hydrochloric acid, add acidic β-mannanase according to the amount of 200U / g guar gum substrate for enzymolysis, and continue to stir and react for about 1 hour at 50°C. After the enzymatic hydrolysis, the temperature was raised to 90°C and kept for 10 minutes to inactivate the enzyme.

[0030] 5. ...

Embodiment 3

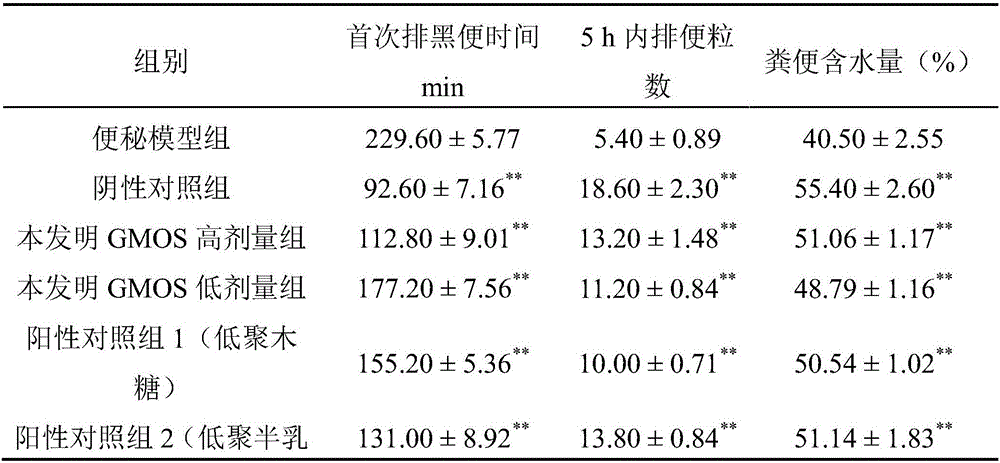

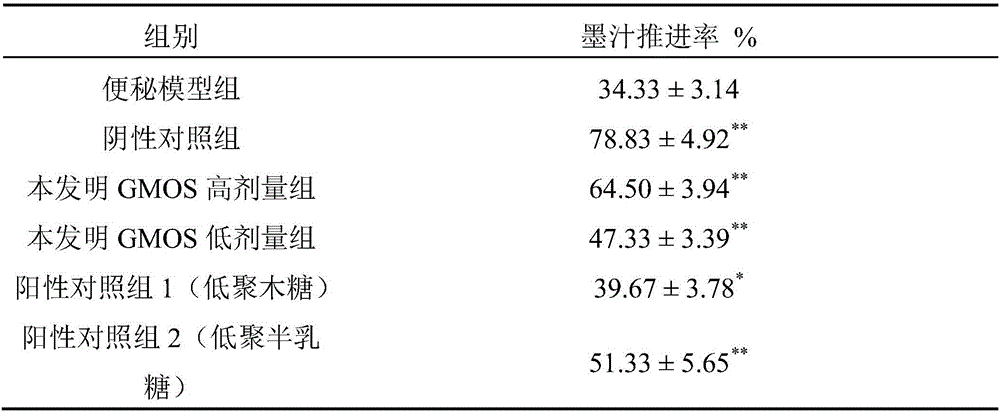

[0035] Comparative observation of the laxative effect of oligosaccharide prepared by the present invention technology and commercial oligosaccharide product:

[0036] The galactomannoligosaccharides of the present invention were prepared according to Example 1.

[0037] Dissolve 1400g of guar gum substrate in 7L of water, add 2mmol / L of ascorbic acid and 40mmol / L of hydrogen peroxide to degrade after dissolving evenly, and shake at 40°C for 0.5h. Add catalase to the reaction solution according to 10000U / L, shake and react at 40°C for 20min. The pH of the reaction solution was adjusted to 2.5 with hydrochloric acid, acid β-mannanase was added according to the amount of 200U / g guar gum substrate for enzymolysis, and the reactor was stirred at 50-55°C for 4-5h. Heat the reaction kettle to 90°C for 10 minutes to inactivate the enzyme, centrifuge at 4800rpm for 20min to remove insoluble enzymolysis residues, and concentrate the supernatant to 2L by suspension evaporation, add 6L o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com