Aqueous inorganic glue and preparation method and application thereof

An inorganic glue, water-based technology, applied in the direction of alkaline batteries, alkaline battery electrodes, electrical components, etc., can solve problems such as insufficient mixing system, performance degradation, leveling or scraping difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Water-based glue containing yttrium and preparation method thereof

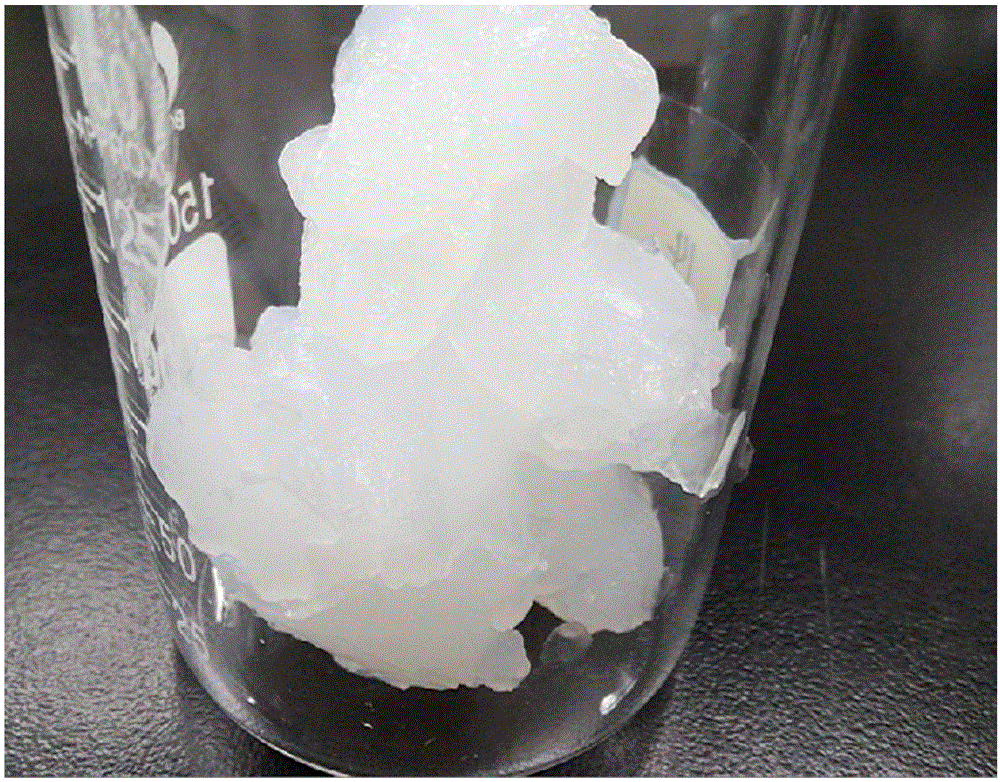

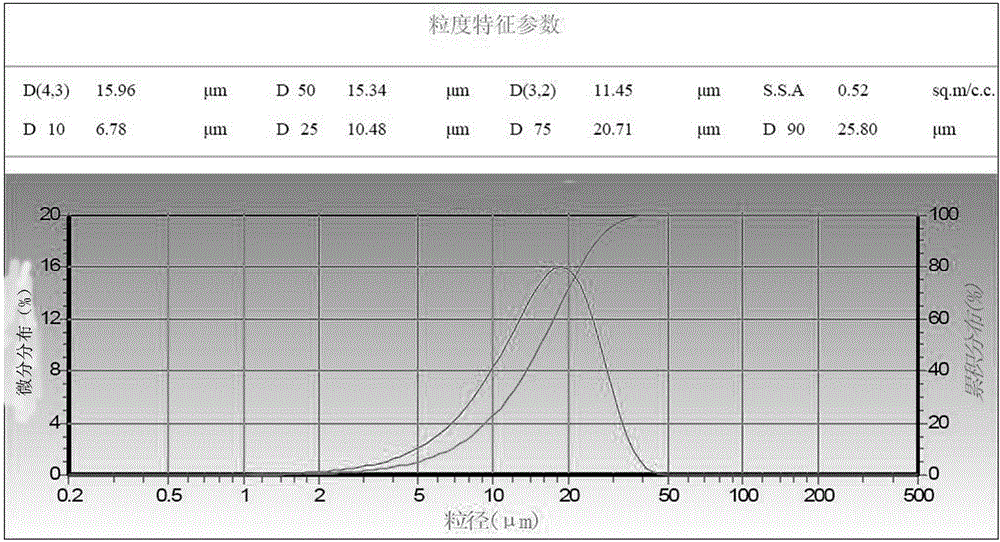

[0046] 1. Preparation steps: mix A L with Y 3+ A mol / L concentration of yttrium-containing soluble salts (such as yttrium sulfate, yttrium nitrate, yttrium chloride, yttrium bromide, etc.) and B L containing OH - Dilute alkali (such as sodium hydroxide, potassium hydroxide) or equivalent weak alkali (such as ammonia water, phosphate, carbonate, borax, silicate, etc.) with a concentration of b mol / L, using two liquids in combination method, add it into the reaction vessel under the condition of ultrasonic vibration and strong stirring at a uniform speed, and after the addition of the two reaction solutions, continue the ultrasonic vibration for H hours, and you can get Y(OH) 3 A stable water-based gel with a mass concentration of m.

[0047] 2. Condition control:

[0048] (1) The values of A and B depend on the amount of Y contained in the water-based glue to be prepared. In theory, B=3A. For the c...

Embodiment 2

[0060] Fabrication of paste-coated nickel electrodes using yttrium hydroxide aqueous gel

[0061] 1. Background introduction: The nickel electrode, which realizes the electrochemical function of the electrode by the reversible conversion of nickel hydroxide and nickel oxyhydroxide under alkaline conditions, is a widely used classic electrode in the field of electrochemistry, such as nickel hydrogen, nickel cadmium, nickel zinc The nickel electrode is used as the positive electrode of the battery in the battery. A common method for making nickel electrodes is to combine nickel hydroxide, cobalt suboxide or hydroxide (or cobalt-coated nickel hydroxide), additives (such as yttrium oxide, ytterbium oxide, magnesium oxide, etc.) , Water-based organic polymer glue (such as CMC, HPMC, HEC, xanthan gum, etc.) is mixed with water to form a wet slurry or paste, filled into a porous nickel foam matrix, then dried and pressed to form a nickel electrode. According to different sizing or p...

Embodiment 3

[0069] Fabrication of pasted hydrogen electrode using yttrium hydroxide aqueous gel

[0070] 1. Background introduction: The negative electrode used in hydrogen electrodes such as nickel-hydrogen batteries is mainly hydrogen-storage alloy powder. For paste-type hydrogen electrodes, the density of hydrogen-storage alloy is about 7g / mL, which is much higher than that of water. Therefore, in order to resist gravity Screening and sedimentation, high usage of thickeners and suspending agents, have obvious negative effects on electrode performance such as rate and self-discharge; on the other hand, the binder SBR used in the negative electrode of Ni-MH batteries has a relatively high viscosity and strong adhesion , combined with a large amount of water-based organic polymer glue, in order to control the viscosity of wet paste, this type of water-based organic polymer glue is mainly low-viscosity and low-concentration gel such as PAAS. From this perspective, yttrium hydroxide water-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com