Nano-fiber surface-modified xenogeneic acellular nerve graft and preparation method thereof

A surface modification, nanofiber technology, applied in fiber treatment, coating, medical science and other directions, can solve the problems of scar formation, affecting the surgical effect, unfavorable nerve connection, etc., to prevent tissue adhesion, firm bonding, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Dissolve polylactic acid-caprolactone copolymer with a weight average molecular weight of 200,000 in hexafluoroisopropanol at a concentration of 0.08g / ml. After stirring at room temperature to form a uniform and stable solution, place it in In the syringe, a high voltage power supply is connected to the needle of the syringe.

[0041] 2. The roller with the xenogeneic decellularized nerve graft fixed on it is used as the collecting device, and the rotating speed is 100 rpm. Start the electrospinning process, control the solution supply flow rate at 1ml / h, apply a voltage of 15KV, and set the distance between the high voltage terminal and the ground terminal at 15cm.

[0042] 3. Washing the collected nanofiber-modified acellular nerve graft with ethanol and deionized water for 12 hours respectively, and repeating 5 times.

[0043] 4. Freeze-dry the product in a freeze dryer (at a temperature of -30°C) for 10 hours, then sterilize it with ethylene oxide and package it...

Embodiment 2

[0046] 1. Dissolve racemic polylactic acid with a weight average molecular weight of 300,000 in dichloromethane at a concentration of 0.075g / ml. After stirring at room temperature to form a uniform and stable solution, put it into a syringe. Connect to high voltage power supply.

[0047] 2. Take the roller fixed with the heterogeneous decellularized nerve as the collection device, and the rotation speed is 250 rpm. Start the electrospinning process, control the solution supply flow rate at 3ml / h, apply a voltage of 12.5KV, and set the distance between the high voltage end and the ground end at 10cm.

[0048] 3. The collected nanofiber-modified acellular nerve graft was washed with ethanol and deionized water for 6 hours each, and repeated 3 times.

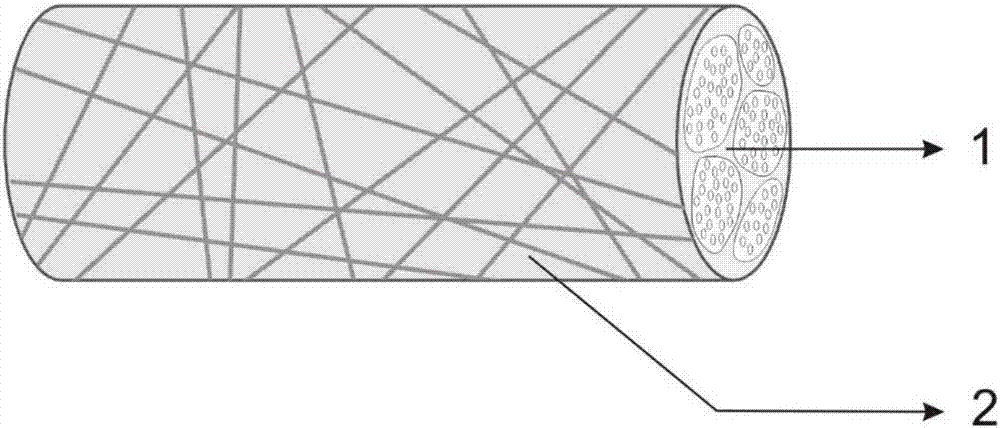

[0049] 4. Freeze-dry the product in a lyophilizer (at a temperature of -20°C) for 8 hours, and then sterilize and package it with cobalt-60 with an irradiation dose of 15KGy to obtain the final product. The schematic diagram is as...

Embodiment 3

[0052] 1. Dissolve polylactic acid-glycolic acid copolymer with a weight average molecular weight of 150,000 in acetone at a concentration of 0.15g / ml. After stirring at room temperature to form a uniform and stable solution, put it into a syringe, and the syringe needle Connect to high voltage power supply.

[0053] 2. Take the roller fixed with the xenogeneic decellularized nerve as the collection device, and the rotation speed is 300 rpm. Start the electrospinning process, control the solution supply flow rate at 2ml / h, apply a voltage of 10KV, and set the distance between the high voltage terminal and the ground terminal at 12.5cm.

[0054] 3. Washing the collected nanofiber-modified acellular nerve graft with ethanol and deionized water for 8 hours respectively, and repeating 4 times.

[0055] 4. Freeze-dry the product in a lyophilizer (at a temperature of -15°C) for 6 hours, then sterilize it with an irradiation dose of 13KGy electron beams and package it to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mass volume concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com