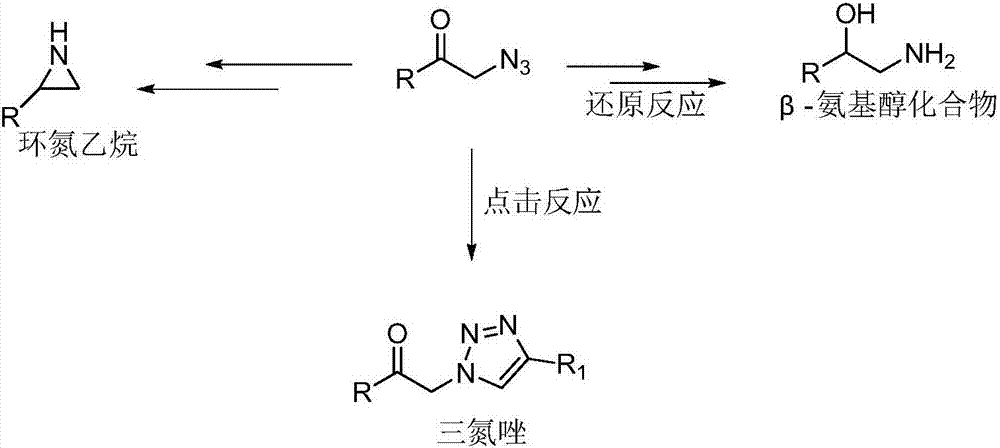

Alpha-azidocarbonyl compounds and preparation method thereof

A technology for azidocarbonyl compounds, which is applied in the field of organic compound synthesis, can solve problems such as insufficiently mild reaction conditions and complicated operation of α-azidocarbonyl compounds, and achieve the effects of simple operation, simple post-treatment, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

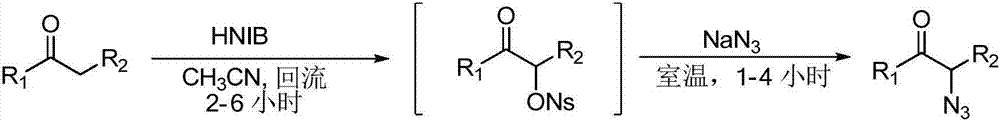

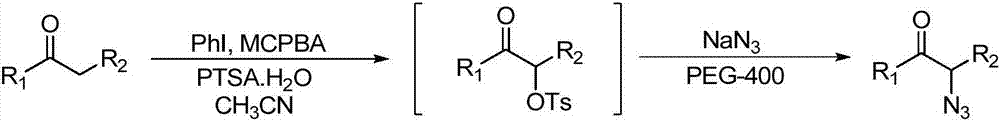

Method used

Image

Examples

preparation example Construction

[0067] In the preparation method of the present invention, the reaction temperature is -80-40°C, non-limitingly, for example, -80°C, -40°C, -20°C, -10°C, 0°C, 10°C or 40°C

[0068] (6) Response time

[0069] In the preparation method of the present invention, the reaction time is not particularly limited. For example, the appropriate reaction time can be determined by detecting the residual percentage of the target product or raw material by liquid chromatography, which is usually 0.5-30 hours, non-limitingly for example 1 hour, 4 hours, 6 hours, 8 hours, 10 hours, 12 hours, 14 hours, 26 hours, 28 hours or 30 hours.

[0070] (7) Separation and purification

[0071] The mixture obtained after the reaction can be further separated and purified to obtain a purer final product. Those of ordinary skill in the art are familiar with the methods of separation and purification, for example, methods such as extraction, column chromatography, distillation, decantation, filtration, cent...

Embodiment 1

[0075] Synthesis of 2-Azide-Acetophenone

[0076]

[0077] At room temperature, copper acetate (5mol%) and potassium persulfate (0.8mmol, 2equiv) were added to the reaction tube, then pumped-oxygenated, and replaced three times, under an oxygen environment, the reaction solvent 2mLDMSO, phenylacetylene ( 0.4mmol, 1equiv), trimethylsilyl azide (1.2mmol, 3equiv), stirred at a reaction temperature of 25°C for 12h; after the reaction was monitored by thin-layer chromatography, 20mL of water and 10mL of ethyl acetate were added for extraction operation, and then added Dry over anhydrous sodium sulfate, filter after 5 minutes, wash the filter cake with ethyl acetate (5mL x 3 times), then spin off the solvent, and obtain the product after separation by column chromatography (elution machine: petroleum ether: diethyl ether=100: 1), the product is a colorless liquid with a yield of 91%;

[0078] The data of the proton nuclear magnetic resonance spectrum of gained product are as fol...

Embodiment 2

[0086] Synthesis of 2-Azido-1-(4-Hydroxyphenyl)ethanone

[0087]

[0088] At room temperature, copper acetate (5mol%), potassium persulfate (0.8mmol, 2equiv) were added to the reaction tube, then pump-filled with oxygen, and replaced three times, under oxygen environment, the reaction solvent 2mLDMSO, 4-hydroxy Phenylacetylene (0.4mmol, 1equiv), trimethylsilyl azide (1.2mmol, 3equiv), stirred at a reaction temperature of 25°C for 12h; after the completion of the reaction was monitored by thin-layer chromatography, 20mL of water and 10mL of ethyl acetate were added for extraction operation , then add anhydrous sodium sulfate to dry, filter after 5 minutes, the filter cake is washed with ethyl acetate (5mL x 3 times), then spin off the solvent, obtain the product after separation by column chromatography (elution machine: petroleum ether: diethyl ether =100:5), the product is a white solid, and the yield is 89%;

[0089] The data of the proton nuclear magnetic resonance spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com