Preparation method of ozone heterogeneous oxidation solid catalyst

A heterogeneous oxidation, solid catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of poor toxicity resistance, easy loss of catalytic activity, Solve the problems of low catalyst adsorption, achieve strong adsorption, improve anti-toxicity and catalytic activity, and inhibit melting and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

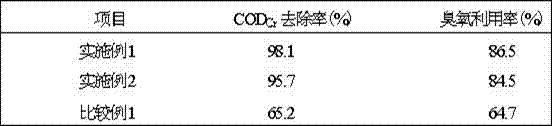

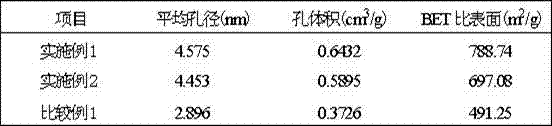

Embodiment 1

[0007] Embodiment 1:1.35g lithium hypochlorite, 1.65g bis(acetylacetonate) beryllium, 140ml deionized water, join volume and be that in the sealable reactor of 500ml, stir and mix evenly, the weight concentration of this aqueous solution is 2.1%, times Lithium chlorate: bis(acetylacetonate) beryllium weight ratio = 1:1.2; add deionized water to wash to neutral, dry at 103°C to remove moisture, and then sieve 2.75g wheat rice of -200 mesh to +400 mesh standard sieve The weight (3g) of lithium hypochlorite and bis(acetylacetonate)beryllite (3g): Weight (31.5g) = 1:10.5, heat up to 36°C, continue to stir for 3.2h, filter, dry at 103°C and obtain 31g of pore-enlarging modified carrier; in a 500ml ultrasonic reactor, put the pore-enlarging modified carrier 31g, then add 3.25g tetradecyltributylammonium chloride and be dissolved in the aqueous solution of 100ml deionized water, the weight concentration of this aqueous solution is 3.1%, stir and mix, tetradecyltributylammonium chlori...

Embodiment 2

[0008] Embodiment 2: 0.24g lithium hypochlorite, 0.36g bis(acetylacetonate) beryllium, 10ml deionized water, join volume and be that in the sealable reactor of 100ml, stir and mix evenly, the weight concentration of this aqueous solution is 5.7%, times Lithium chlorate: bis(acetylacetonate) beryllium weight ratio = 1:1.5; add deionized water to wash to neutral, dry at 103°C to remove moisture, and then sieve 1.45g wheat rice of -200 mesh to +400 mesh standard sieve Weight (0.6 g) of Lithium Hypochlorite and Bis(acetylacetonate)Beryllite, 1.65 g wollastonite, 1.85 g activated carbon, 2.05 g carnallite, 2.25 g illite, 2.45 g sodium borite, lithium hypochlorite and beryllium bis(acetylacetonate) : porous material The weight (11.7g)=1:19.5, heat up to 48°C, continue to stir and react for 5.8h, filter, dry at 105°C and obtain 11.5g of pore-enlarging modified carrier; in a 100ml ultrasonic reactor, put the pore-enlarging modified Carrier 11.5g, add the aqueous solution that 2.2g tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com