A kind of degumming agent for photosensitive waste film and its application and reusing method of degumming agent

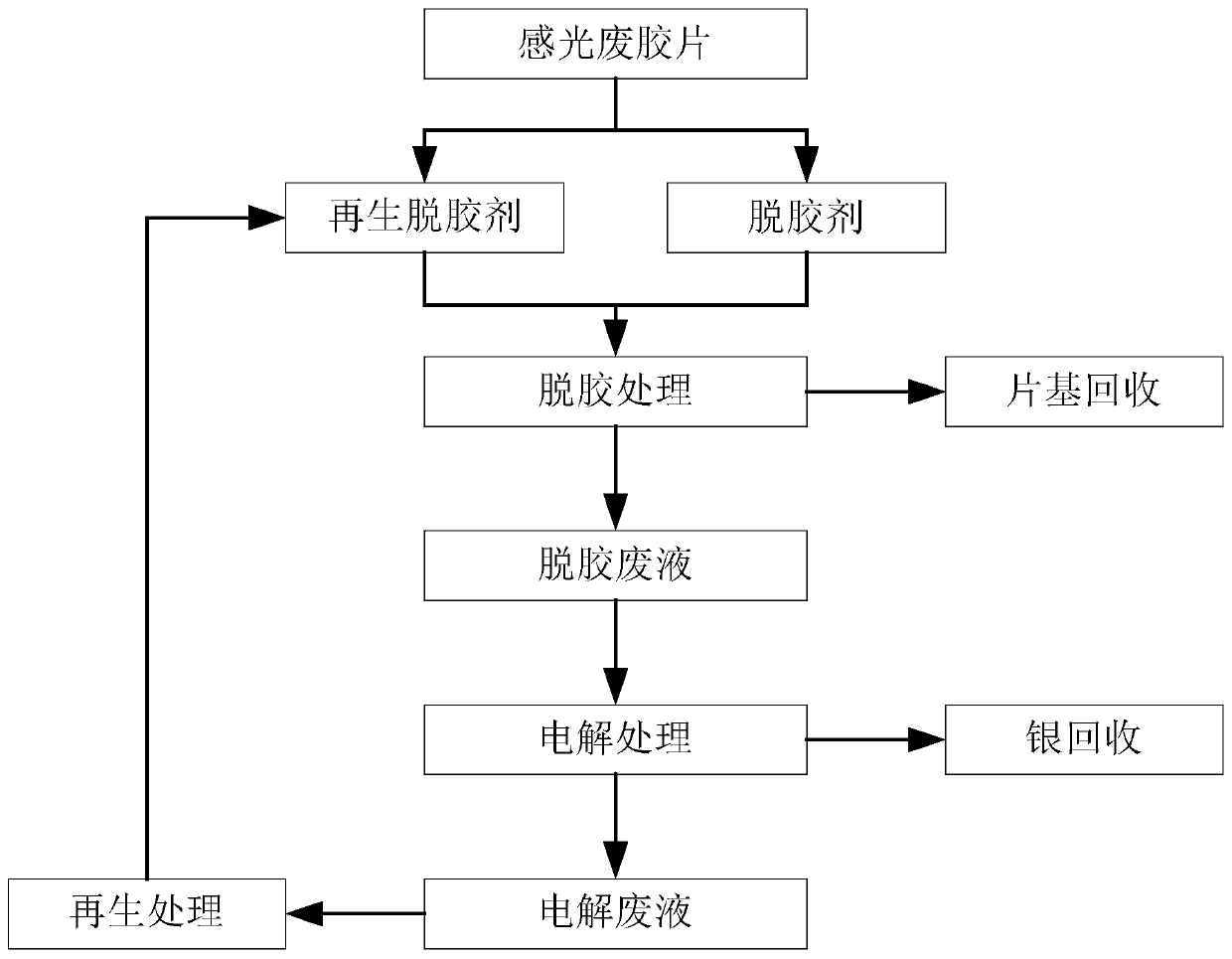

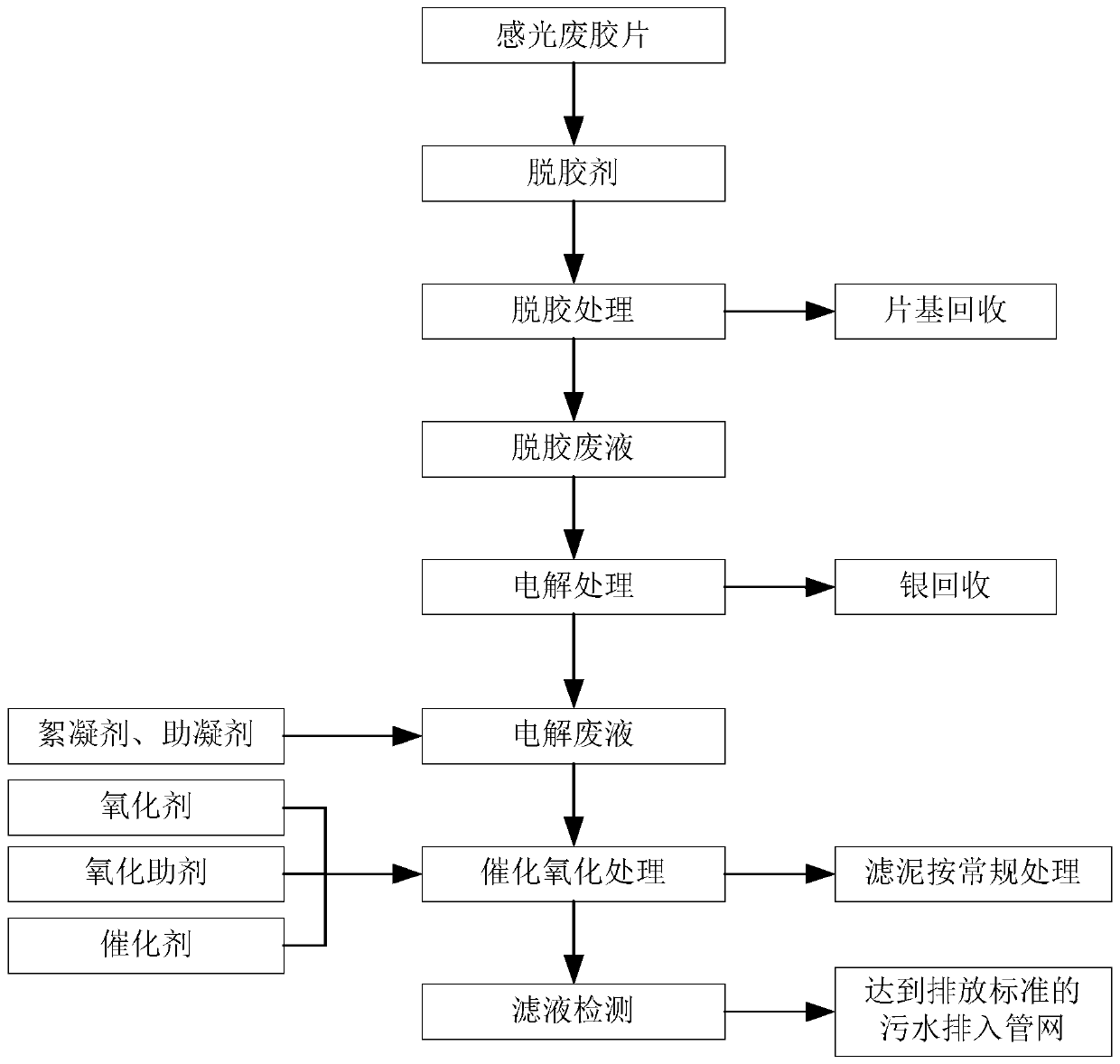

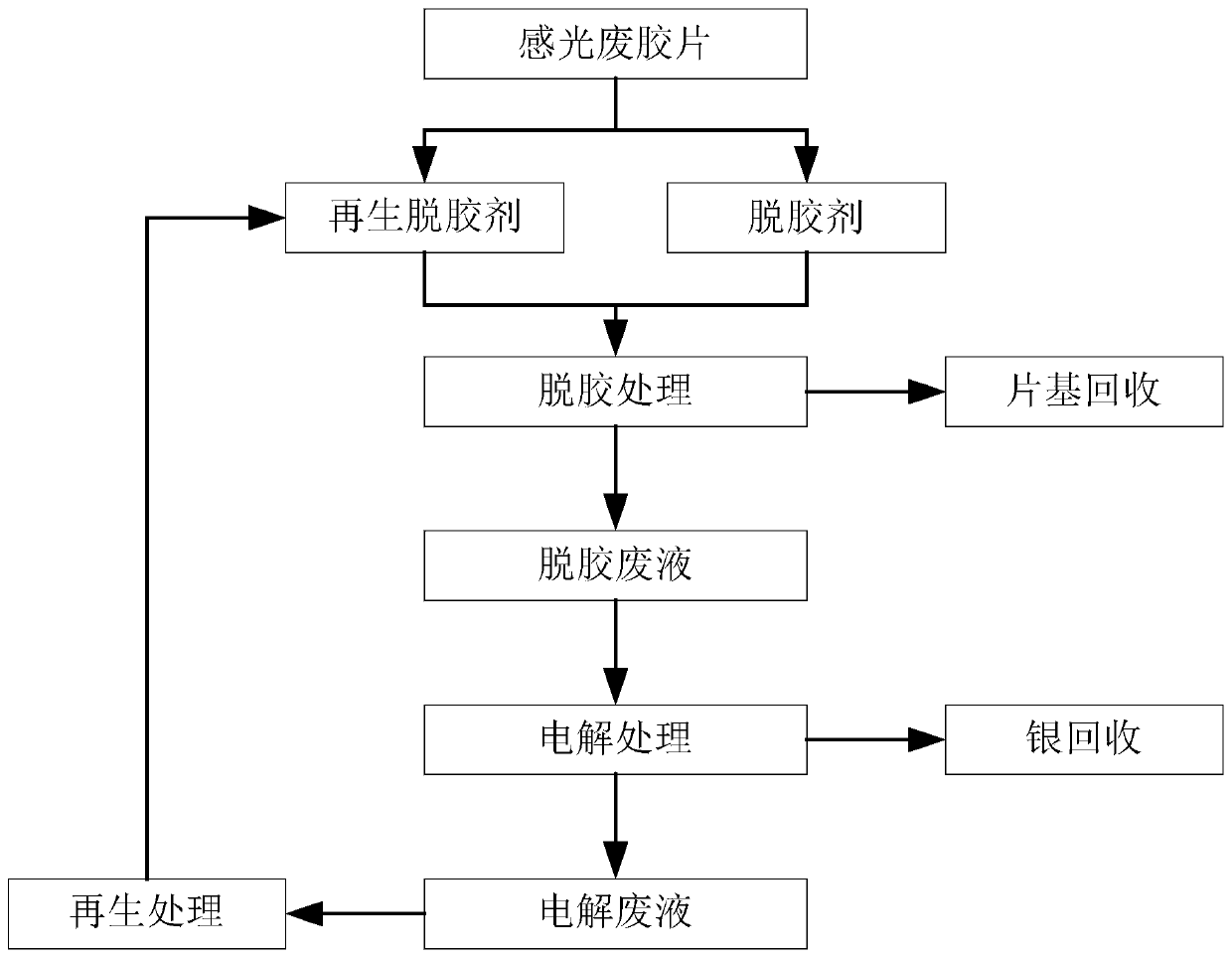

A degumming agent and film technology, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of difficulty in silver recovery, separation of emulsifier layer and film base, and difficulty in reusing degumming agents. , to achieve the effect of saving degumming cost, simple preparation method and complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides a kind of degumming agent of photosensitive waste film, comprises the raw material of following quality:

[0057] Alkaline solution 21.115Kg;

[0058] Penetrant 0.0106Kg;

[0059] Dispersant 0.015Kg;

[0060] Wherein, the alkaline solution is prepared by adding sodium hydroxide to water; the penetrating agent is C8-10 alcohol polyoxyethylene ether; the dispersing agent is polyethylene glycol.

[0061] This embodiment provides a method for preparing a photosensitive waste film degumming agent using the above-mentioned raw materials, comprising the following steps:

[0062] Add 0.615Kg of sodium hydroxide to 20.5Kg of water to prepare a 3% alkaline solution (PH value is 13.88); add 0.0106Kg C8-10 alcohol polyoxyethylene ether, which is 0.5% of the mass of the alkaline solution; add 0.015 Kg polyethylene glycol is 0.7% of the alkali solution quality. Mix evenly and let it stand for 10 minutes to obtain a photosensitive waste film degummi...

Embodiment 2

[0064] The present embodiment provides a kind of degumming agent of photosensitive waste film, comprises the raw material of following quality:

[0065] Alkaline solution 22.36Kg;

[0066] Penetrant 0.151Kg;

[0067] Dispersant 0.194Kg;

[0068] Wherein, the alkaline solution is prepared by adding sodium hydroxide to water; the penetrating agent is propylene glycol polyoxyethylene ether; and the dispersing agent is calcium stearate.

[0069] This embodiment provides a method for preparing a photosensitive waste film degumming agent using the above-mentioned raw materials, comprising the following steps:

[0070] Add 0.86Kg of sodium hydroxide to 21.5Kg of water to prepare an alkaline solution with a mass fraction of 4% (PH value is 14); add 0.151Kg of propylene glycol polyoxyethylene ether, which is 0.7% of the mass of the alkaline solution; add 0.194Kg of hard Calcium fatty acid is 0.9% of the mass of the alkali solution. Mix evenly and let it stand for 12 minutes to obta...

Embodiment 3

[0072] The present embodiment provides a kind of degumming agent of photosensitive waste film, comprises the raw material of following quality:

[0073] Alkaline solution 24.34Kg;

[0074] Penetrant 0.288Kg;

[0075] Dispersant 0.312Kg;

[0076] Among them, the alkaline solution is prepared by adding sodium hydroxide to water; the penetrating agent is lauric acid random polyether; the dispersing agent is stearic acid amide.

[0077] This embodiment provides a method for preparing a photosensitive waste film degumming agent using the above-mentioned raw materials, comprising the following steps:

[0078] Add 1.14Kg of sodium hydroxide to 23.2Kg of water to prepare a 5% alkaline solution (PH value of 14); add 0.288Kg lauric acid atactic polyether, which is 1.2% of the mass of the alkaline solution; add 0.312Kg Stearic acid amide is 1.3% of the alkali solution quality. Mix evenly and let it stand for 15 minutes to obtain a photosensitive waste film degumming agent, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com