A method for efficiently preparing mannose acid by multi-microbial step-by-step fermentation

A mannose acid, step-by-step fermentation technology, applied in the field of bioengineering and chemical engineering, can solve problems such as difficulties and achieve the effect of improving product yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

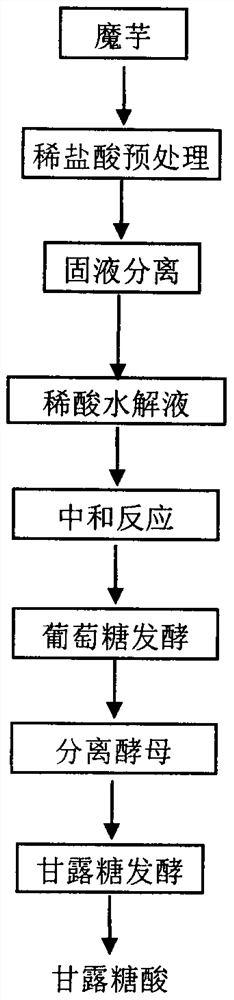

Image

Examples

Embodiment example 1

[0022] In a 250ml Erlenmeyer flask system, add 50mL of 50g / L mannose and 30g / L glucose solution. First, insert Saccharomyces cerevisiae to a cell concentration of 2g / L (dry basis) and place it in a constant temperature reactor at 170rpm and 30°C for anaerobic ethanol fermentation. After 16 hours of reaction, the glucose concentration is lower than 3g / L and the remaining mannose is 44.5g / L to stop the ethanol fermentation. reaction. The centrifugation method was adopted, and the Saccharomyces cerevisiae was fully settled by centrifugation under the condition of 6000rpm for 10min. The isolated ethanol fermentation broth containing a large amount of mannose was inoculated into Gluconobacter oxydans to a cell concentration of 8 g / L (dry basis), and placed in a constant temperature reactor at 220 rpm and 30° C. for whole-cell catalysis. Add 10g / L calcium carbonate to maintain the pH value of the catalytic system at around 4.5-6.0. Stop the reaction until the mannose is completely...

Embodiment example 2

[0024] 1000g (dry basis) konjac is mechanically ground to powder, transferred to a 15L stainless steel cooking kettle, added 1.25% dilute hydrochloric acid, and the solid-liquid ratio (1:10, w / v) is fully impregnated. Heating to 120° C. with an electric jacket, reacting for 60 minutes, and filtering to obtain a dilute hydrochloric acid hydrolyzate, which contains 44.2 g / L mannose and 25.9 g / L glucose. The dilute acid hydrolyzate was neutralized to pH 6.5 by calcium hydroxide and then transferred to a 15L mechanically stirred reactor. Add Candida shohata to a cell concentration of 2g / L (dry basis). The reaction temperature was controlled at 28-30° C. and the mechanical stirring rate was 300 r / min, and the concentration of glucose and mannose in the hydrolyzate and the recovery rate of mannose were monitored by high-performance liquid chromatography. After 12 hours of reaction, the concentration of glucose in the acid hydrolyzate was lower than 2g / L, and the recovery rate of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com