Method for preparing single crystal wide-band gradient LED phosphor

A phosphor and gradient technology, which is applied in the field of LED solid-state lighting systems, can solve problems affecting the photoelectric conversion rate of broad-spectrum gradient phosphor quality and industrial production, application limitations, and difficulty in controlling the size of single crystal grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

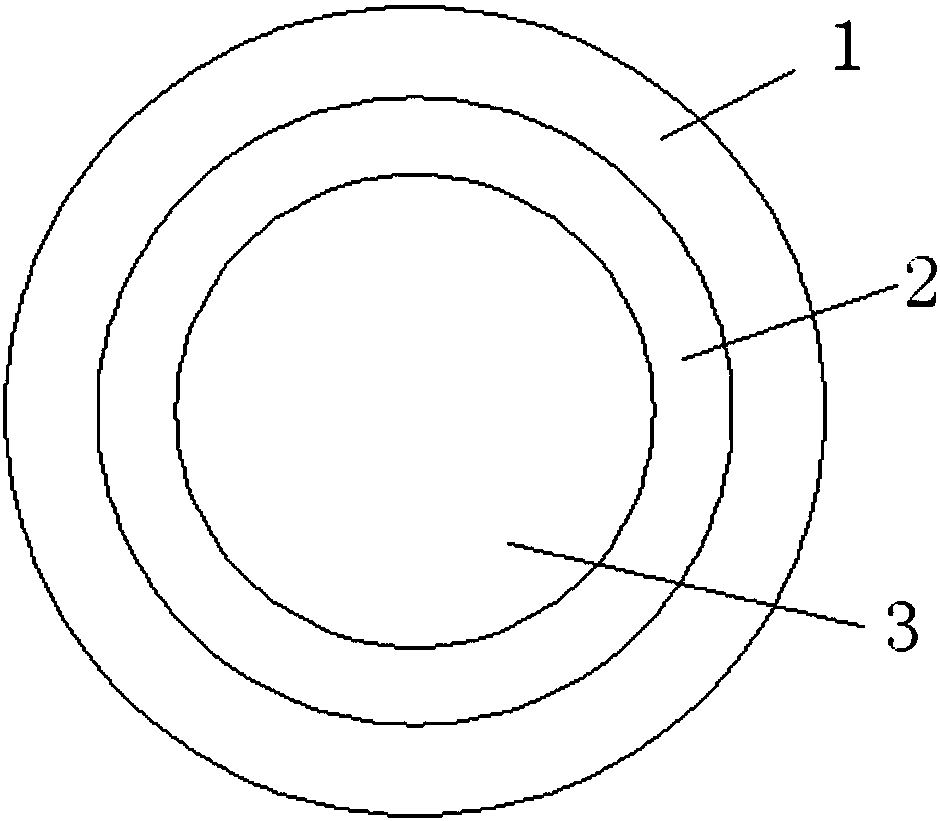

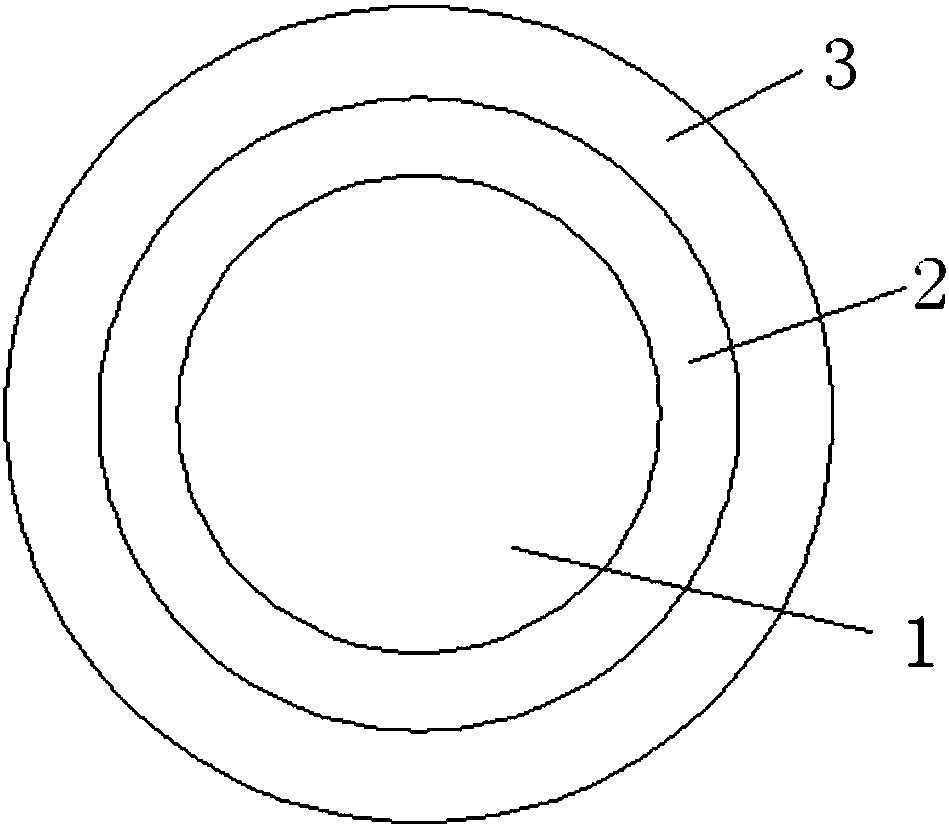

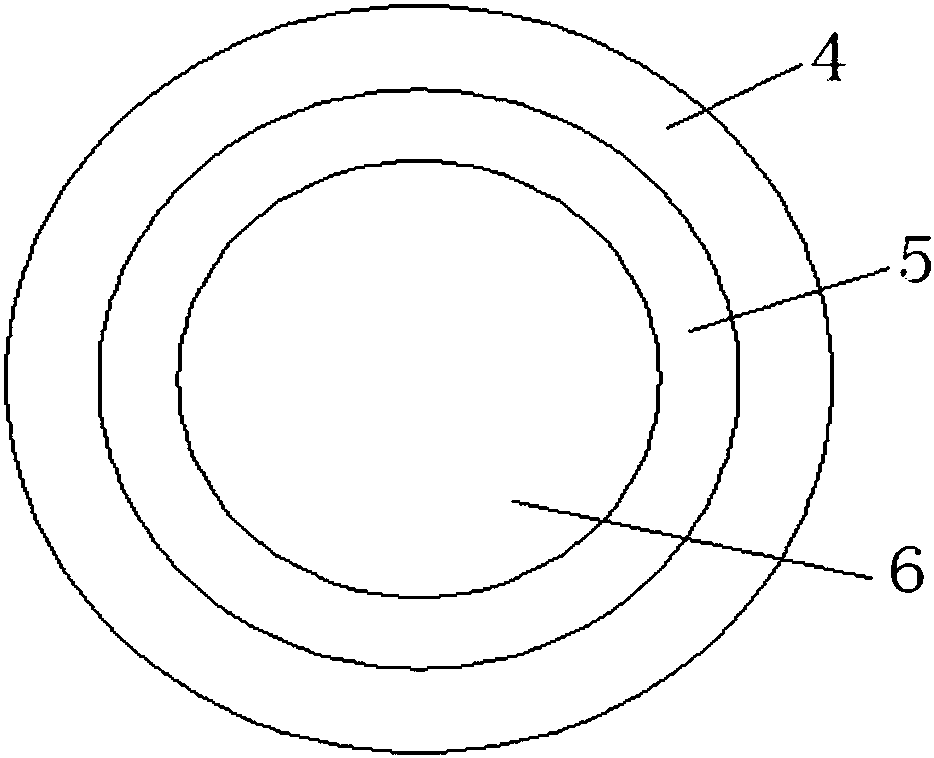

Image

Examples

Embodiment 1

[0081] The present invention will be further described below in conjunction with the preparation of YAG series broadband gradient phosphors.

[0082] 1. The raw materials and reagents used in this example are as follows:

[0083] Yttrium oxide (Y 2 o 3 ≥99.99%) or yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O≥99.99%); cerium nitrate (Ce(NO) 3 ·6H 2 O, analytically pure); aluminum nitrate (Al(NO 3 ) 3 9H 2 O, analytically pure); gallium nitrate (Ga(NO 3 ) 3 9H 2 O, analytically pure), gadolinium nitrate (Gd(NO 3 ) 3 ·6H 2 O, analytically pure), concentrated nitric acid HNO 3 , analytically pure; absolute ethanol, C 2 h 5 OH, analytically pure; distilled water H 2 O; ammonium bicarbonate (NH 4 HCO 3 , analytically pure); ammonia water (NH 3 ·H 2 O, analytically pure); polyethylene glycol (PEG1000). 2. The experimental equipment used in this embodiment is as follows:

[0084]Conventional glass apparatus; dryer; pure water system; fully automatic electronic analytica...

Embodiment 2

[0130] BSS-A, BSS-B series broadband gradient phosphor preparation process such as Figure 7 and Figure 8 Shown:

[0131] 1 Raw materials and reagents:

[0132] Barium oxide (BaO≥99.99%) or barium nitrate (Ba(NO 3 ) 2 ≥99.99%); strontium oxide (SrO≥99.99%) or strontium nitrate (Sr(NO 3 ) 2 ≥99.99%); europium nitrate (Eu(NO 3 ) 3 6H2O, analytically pure); ethyl orthosilicate (Si(OC 2 h 5 ) 4 , analytically pure); concentrated nitric acid HNO 3 , analytically pure; absolute ethanol, C 2 h 5 OH, analytically pure; distilled water H 2 O; ammonium bicarbonate (NH 4 HCO 3 , analytically pure); ammonia water (NH 3 ·H 2 O, analytically pure); polyethylene glycol (PEG1000)

[0133] 2 experimental equipment

[0134] Conventional glass apparatus; dryer; pure water system; fully automatic electronic analytical balance; constant temperature magnetic stirrer; electric heating constant temperature water tank; pH acidity meter; Drying box; agate mortar; high-temperature g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com