UV-LED curing initiation system, sealing glue, and preparation method and application of sealing glue

A UV-LED, initiation system technology, applied in the field of chemical materials, can solve the problems of short service life, decreased acid and alkali resistance of the sealant, low efficiency, etc., to achieve the effect of operable quality and avoid the phenomenon of oxygen inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

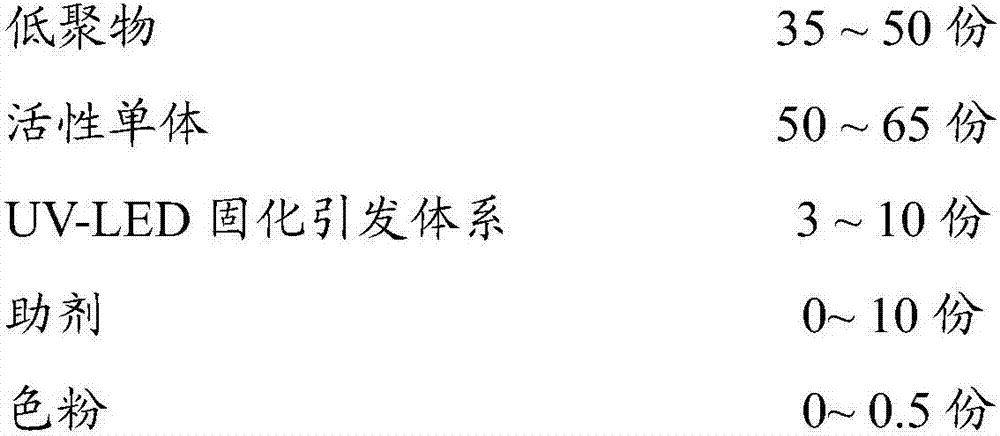

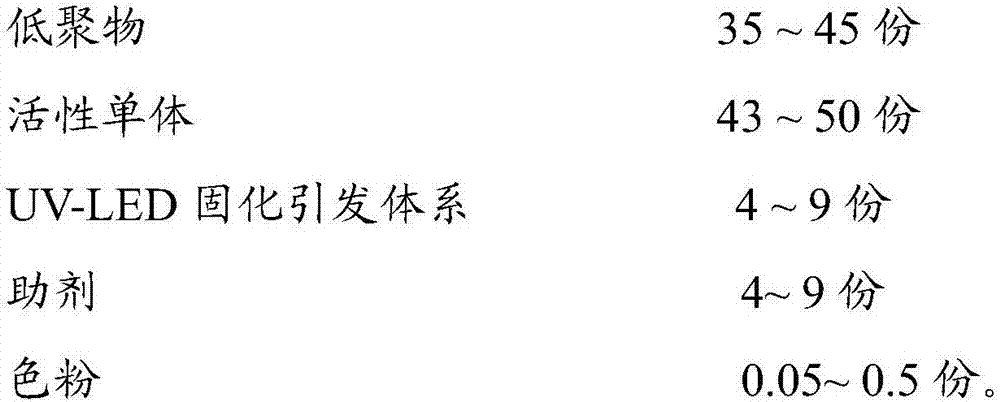

Method used

Image

Examples

Embodiment 1

[0059] A UV-LED curing sealant for glass thinning process, which is a light red UV-LED light curing product, prepared from the following raw materials:

[0060] Oligomers: 41.52 g in total.

[0061] Urethane acrylate 41.52g.

[0062] Active monomer: 46.69 g in total.

[0063] Monofunctional acrylate, isobornyl acrylate (IBOA) 38.20g,

[0064] Difunctional acrylate, dioxyhexadiol diacrylate 8.49g.

[0065] UV-LED curing initiation system: 6.79g in total.

[0066] Cleavage type free radical photoinitiator: 2-hydroxyl-2-methyl-phenylacetone-1 (liquid) 2.00g,

[0067] [Bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide] (solid) 2.00 g.

[0068] Hydrogen abstraction free radical photoinitiator: 2.79 g of isopropylthioxanthene (solid).

[0069] Additives: 5.00 g in total.

[0070] Adhesion promoter (γ-methacryloxypropyltriethoxysilane) 0.95g,

[0071] (multifunctional thiol compound, model is PE-LED) 3.47g,

[0072] Defoamer (silicone defoamer, model BYK066N) 0.3g,

[0073] ...

Embodiment 2

[0090] A UV-LED curing sealant for glass thinning process, which is a red transparent UV light curing product, prepared from the following raw materials:

[0091] Oligomers: 44.35 g in total.

[0092] Polybutadiene acrylate 44.35g.

[0093] Active monomer: 43.33 g in total.

[0094] Monofunctional Acrylate, Lauric Acrylate 26.00g,

[0095] Difunctional acrylate, tricyclodecane dimethanol diacrylate 17.33g.

[0096] UV-LED curing initiation system: 7.00 g in total.

[0097] Cracking type free radical photoinitiator: 1-hydroxycyclohexyl phenyl ketone (solid) 2.0g,

[0098] 2,4,6-Trimethylbenzoyl-diphenylphosphine oxide (solid) 2.0 g.

[0099] Hydrogen abstraction radical photoinitiator: isopropylthioxanthene (solid) 3.00.

[0100] Additives: 4.97g in total.

[0101] Adhesion promoter (γ-methacryloxypropyltriethoxysilane) 0.95g,

[0102] (multifunctional thiol compound, model is PE-LED) 3.47g,

[0103] Defoamer (silicone defoamer, model BYK066N) 0.3g,

[0104] Leveling ...

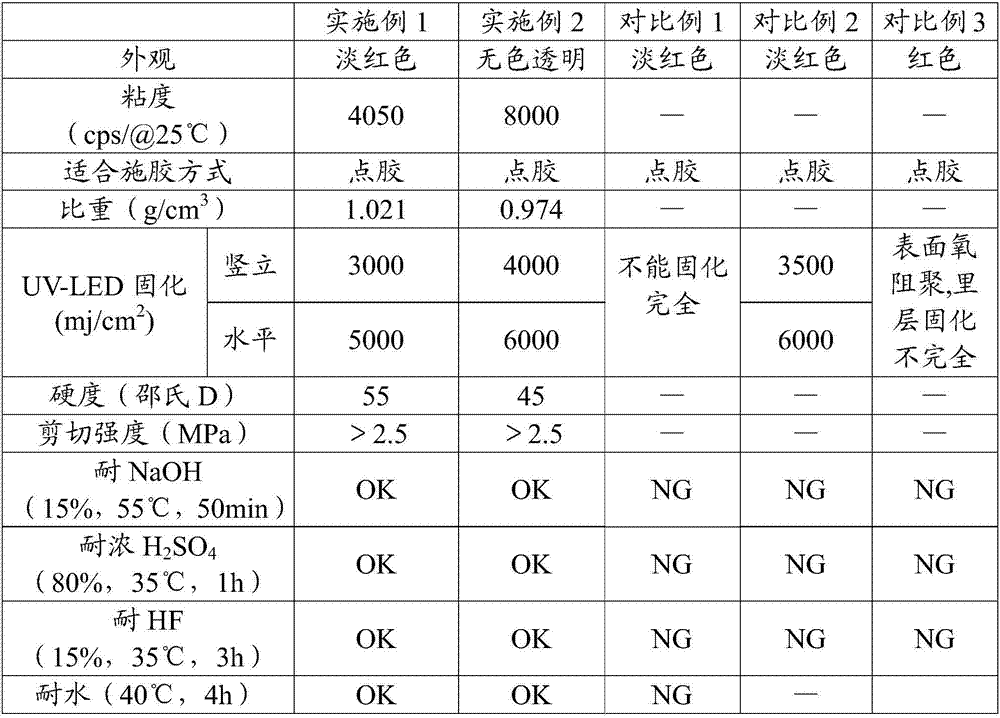

experiment example

[0131] The thinned sealants prepared in the above examples and comparative examples were subjected to performance testing after screen printing, the method is as follows:

[0132] Viscosity: Viscosity at 25°C, tested according to the standard "GB / T 22314-2008 Viscosity Test Method of Plastic Epoxy Resin".

[0133] Specific gravity: 25°C, according to the standard "GB / T 15223-2008 Determination of density of plastic liquid resin by pycnometer method".

[0134] Hardness: 23±2°C, according to the standard "GB / T 2411-2008 Determination of indentation hardness (Shore hardness) of plastics and hard rubber using a durometer (Shore hardness)".

[0135] Shear strength: Test according to the standard "Determination of Tensile Shear Strength of Adhesives", the bonding area is 25mm×6mm, glass is glued to glass, the tensile speed is 5mm / min, and 10 pieces are tested in each group data.

[0136] Resistant to concentrated H 2 SO 4 : After being glued on two pieces of glass for four weeks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com