Preparation method of phosphate water reducer with amide structure

A phosphoric acid-based, water-reducing agent technology, which is applied in the synthesis and application of phosphoric-acid-based water-reducing agents, can solve problems such as low clay sensitivity, and achieve the effects of simple preparation process, simple synthesis method, and excellent clay tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

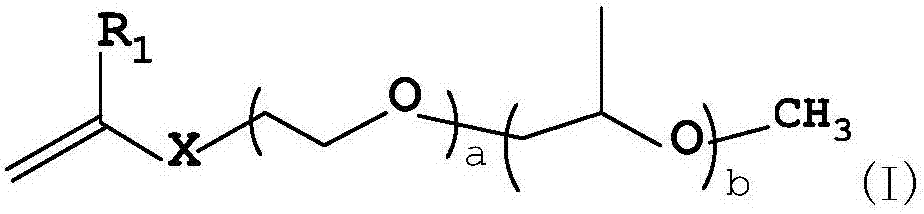

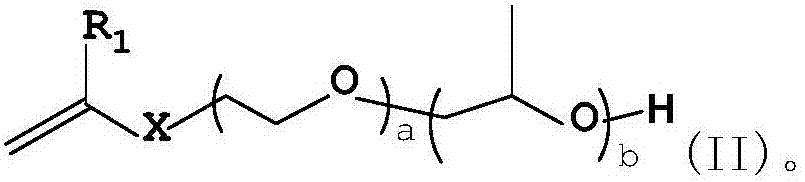

Method used

Image

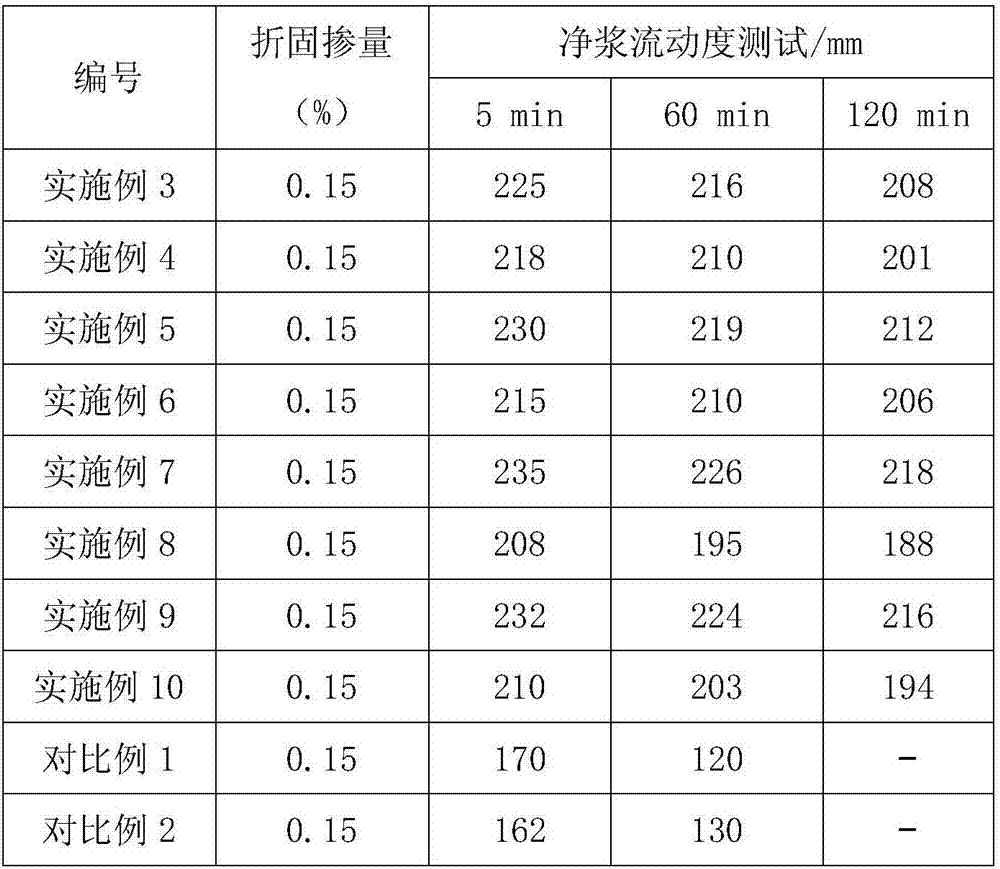

Examples

Embodiment 1

[0045] Preparation of ethylene oxide polyether:

[0046] The initiator is allyl alcohol, and the catalyst is potassium tert-butoxide. Weigh 58 parts of allyl alcohol and 0.9 part of potassium tert-butoxide, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 80° C., and 20 parts of ethylene oxide was introduced into the reaction kettle. After the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 910 parts of ethylene oxide into the reaction kettle. During the feeding process, keep the temperature of the reaction kettle between 120-130°C and the pressure between 0.2-0.4MPa. After the addition of ethylene oxide, keep the temperature at 100°C for 1h about. Until the pressure of the reactor no longer decreases, reduce the temperature of the reactor to about 80°C, open the vent valve to re...

Embodiment 2

[0054] Preparation of ethylene oxide, propylene oxide block polyether:

[0055] Initiator hydroxyethyl vinyl ether, catalyst potassium tert-butoxide. Weigh 88 parts of hydroxyethyl vinyl ether and 4.4 parts of potassium tert-butoxide, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 80° C., and 20 parts of ethylene oxide was introduced into the reaction kettle. After the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 1595 parts of ethylene oxide in the reactor, until the pressure in the reactor no longer drops, 283 parts of propylene oxide in the reactor. During the feeding process, the temperature of the reactor is maintained between 110-115°C and the pressure is between 0.3-0.5MPa. After all the alkylene oxide is fed, the temperature is kept at 100°C for about 1 hour. Until th...

Embodiment 3

[0062] Synthesis of prepolymers containing carboxylic acid groups:

[0063] In the reaction kettle equipped with a temperature measuring device, a stirring device, a titration device and a nitrogen gas introduction pipe, add 500 parts of unsaturated polyether monomer P1, and add 381 parts of solvent water at the same time, purging the reactor with nitrogen while stirring, and Raise the temperature to 70°C and stir well, then add 3.4 parts of hydrogen peroxide (mass concentration: 30%). Then mix 72 parts of acrylic acid, 2.6 parts of L-ascorbic acid, 4.1 parts of thioglycolic acid, and 763 parts of water, stir to form a uniform aqueous solution, and drop it into the reactor for 3.5 hours. 1.5h, cooled to room temperature. The sample was tested by GPC to have a molecular weight of 5720 and a molecular weight distribution of 1.50.

[0064] Synthesis of Phosphate-based Water Reducer:

[0065] Add 31.3 parts of concentrated sulfuric acid and 54.1 parts of ethylenediamine to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com