Oil suspending agent of pesticide and preparation method of oil suspending agent

A technology of oil suspension and pesticide, applied in the field of pesticide oil suspension and its preparation, can solve the problems of large amount of pesticide application, poor use effect, difficulty in emulsification and dispersion, etc., achieve outstanding pesticide application effect, easy adhesion, and reduce application The effect of the dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

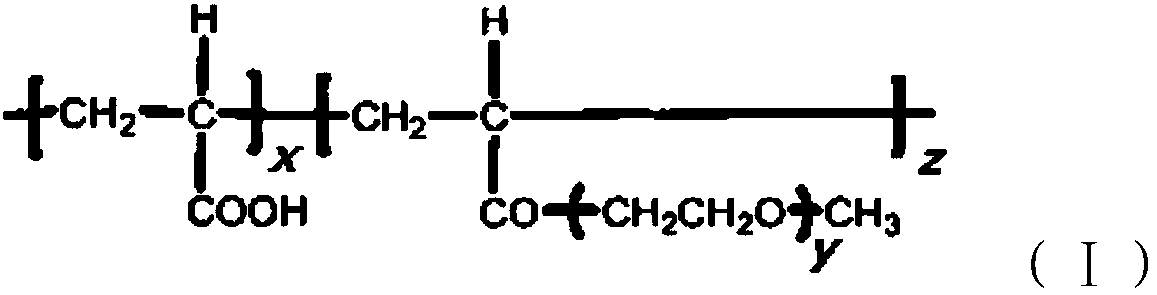

[0038] Preparation of alkylbenzene sulfonic acid polycarboxylate potassium salt copolymer:

[0039] Add a certain amount of polycarboxylic acid intermediate to the reaction flask, start stirring, slowly raise the temperature and reflux to 90°C, start to slowly add sodium dodecylbenzene sulfonate, among which, the polycarboxylic acid intermediate and dodecyl The molar ratio of sodium benzene sulfonate is 7:1, and the reaction is constant for 4 hours. After the reaction is complete, the temperature is lowered to 30°C, and a 40% potassium hydroxide aqueous solution is added to adjust the pH to 8.0-9.0. The temperature is lowered to -5°C and dried by suction filtration, and the filtered product is the alkylbenzene sulfonic acid polycarboxylate potassium salt copolymer.

[0040] The polycarboxylic acid intermediate is an existing commodity.

[0041] Preparation of compound emulsifier:

[0042] Disperse styrene-based phenol polyoxyethylene ether, polyol fatty acid ester and its ethylene o...

Embodiment 2

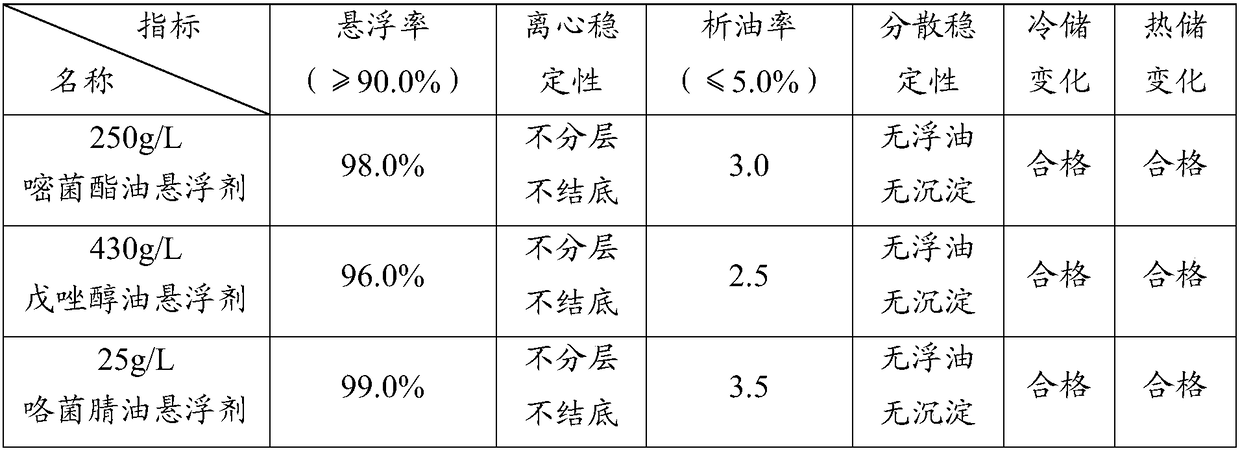

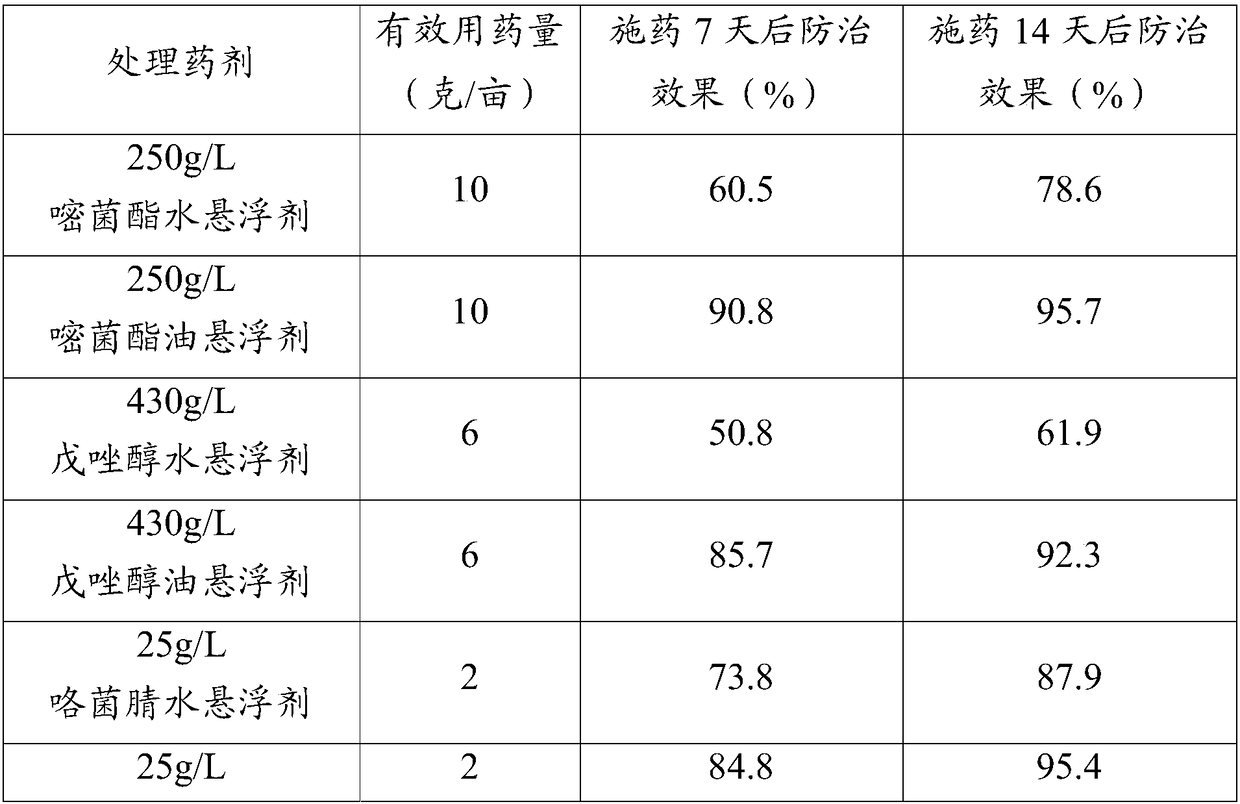

[0044] Preparation of 250g / L azoxystrobin oil suspension concentrate:

[0045] After the azoxystrobin technical drug is refined and dried and all the indicators are qualified, it is pulverized by ultra-fine jet until the particle size reaches D 90 ≤5.0μm, add 67.0% soybean oil and 10.0% compound emulsifier to the batching kettle, stir to form a uniform mixed solution; add 23.0% ultrafine pulverized azoxystrobin powder, high-speed shearing and stirring to form a water-like emulsion State, detect particle size D 90 ≤5.0μm, sampling and testing, transport to finished product storage tank after qualified, and then package into products.

[0046] Among them, the composite emulsifier is composed of the following parts by weight: 14 parts of tristyryl phenol polyoxyethylene ether (Nongru 600#), 16 parts of Tween-60, 11 parts of dioctyl butenedioate calcium sulfonate, 10 parts of alkylbenzene sulfonic acid polycarboxylate potassium salt copolymer, 35 parts of solvent oil 180#, 7.5 parts of...

Embodiment 3

[0052] Preparation of 430g / L tebuconazole oil suspension concentrate:

[0053] According to the weighed 40.0% tebuconazole, 48% methyl oleate and 12.0% compound emulsifier are added to the batching kettle 1, fully stirred to form a mixed uniform solution; continuous sanding by a horizontal sand mill, control Granularity D 90 ≤5.0μm, after the particle size is qualified, transfer to the batching kettle 2; high-speed shearing and stirring to form a state similar to water emulsion, check the particle size D 90 ≤5.0μm; sampling and testing, after passing the test, it will be transported to the finished product storage tank and packaged into products.

[0054] Among them, the composite emulsifier is composed of the following parts by weight: 15 parts of Nongru 600#, 14 parts of Tween-80, 10 parts of butenedioic acid dilauryl ester sulfonate magnesium, 10 parts of alkylbenzene sulfonic acid polycarboxylic acid Potassium salt copolymer, 39 parts of solvent naphtha 150#, 8 parts of propyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com