A kind of preparation method of cobalt element doped tio2 nanotube

An element-doped, nanotube technology, applied in the fields of photocatalytic materials and solar energy utilization, to achieve the effect of improving photovoltage and filling factor, inhibiting recombination, and excellent photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of cobalt doped titanium sol

[0031] Put 40mL of deionized water and 5mL of hydrochloric acid in a three-necked flask, and slowly add 50mL of TiCl dropwise under stirring 4 , continue stirring for 1 h after dropping, and stand in the dark for 24 h to obtain a titanium sol; according to the molar ratio of Co / Ti of 1%, 0.05M cobalt nitrate solution is added dropwise to the titanium sol to obtain a cobalt-doped titanium sol .

[0032] (2) Preparation of cobalt doped TiO 2 Nano powder

[0033] In a three-neck flask equipped with 25mL deionized water and 25mL ethanol, under stirring conditions, slowly add the cobalt element-doped titanium sol and ammonia water dropwise, and then continue to drop a small amount of ammonia water after the sol is added dropwise until the pH value 8 to 9, the cobalt-doped titanium gel is obtained; the gel is dried at 100°C and fired at 650°C for 1 hour to obtain cobalt-doped TiO 2 Nano powder.

[0034] (3) Preparation of co...

Embodiment 2

[0038] Steps (1) and (2) are the same as in Example 1.

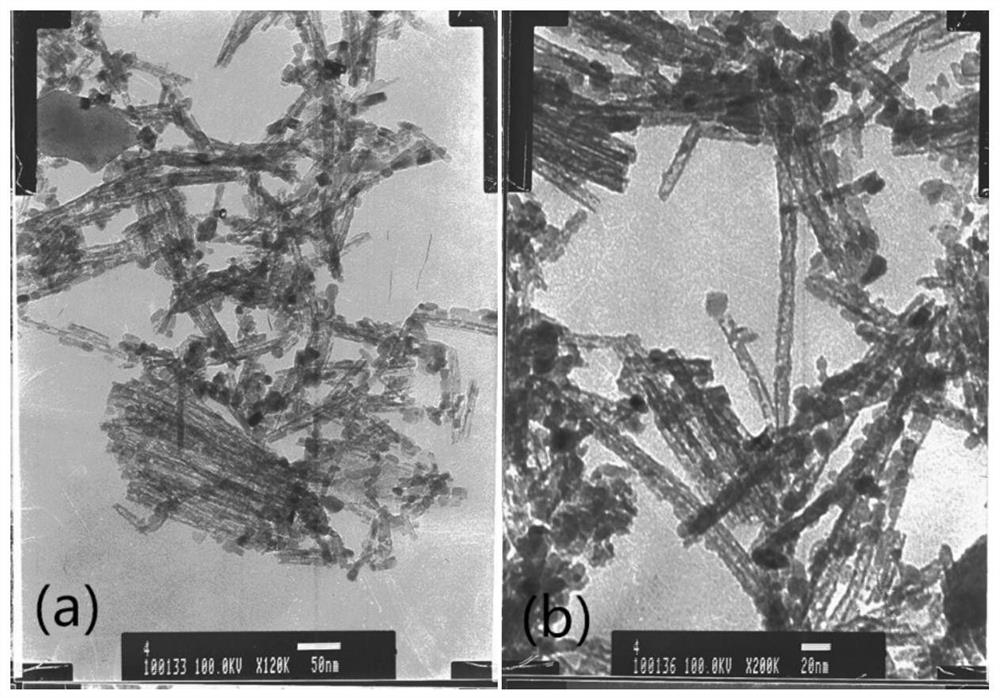

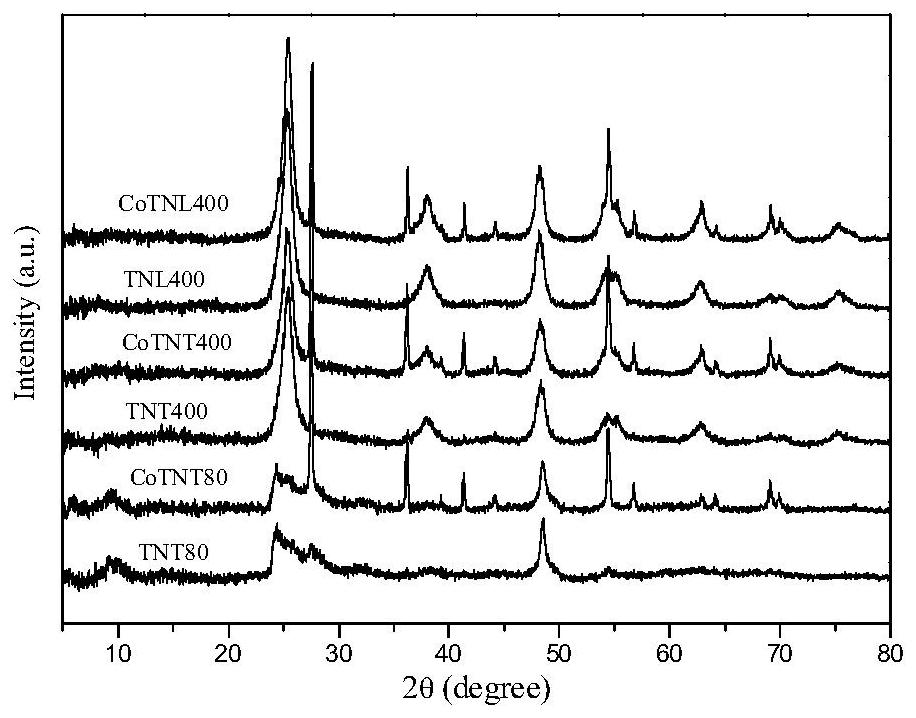

[0039] (3) Preparation of cobalt-doped TiO by hydrothermal synthesis combined with liquid deposition 2 nanotube

[0040] A, the cobalt element that step (1) makes is doped TiO 2 2g of nanopowder and 40mL of 10M NaOH solution were placed in a stainless steel hydrothermal reaction kettle, hydrothermally reacted at 140°C for 48h, after the reaction was completed, cooled to room temperature, the white precipitate was taken out, and washed several times with deionized water until the supernatant was neutral , and then soaked in 0.1M HCl solution for 5h, and continued to wash several times with deionized water until the supernatant was neutral, and dried the white precipitate at 80°C, and the dried sample was marked as CoTNT80.

[0041] B. Weigh 0.2g CoTNT80 and place it in a mixture of 125mL 0.1mol / L ammonium fluotitanate solution and 125mL 0.3 mol / L boric acid solution, liquid phase deposition for 80min, dry at 80°C and co...

Embodiment 3

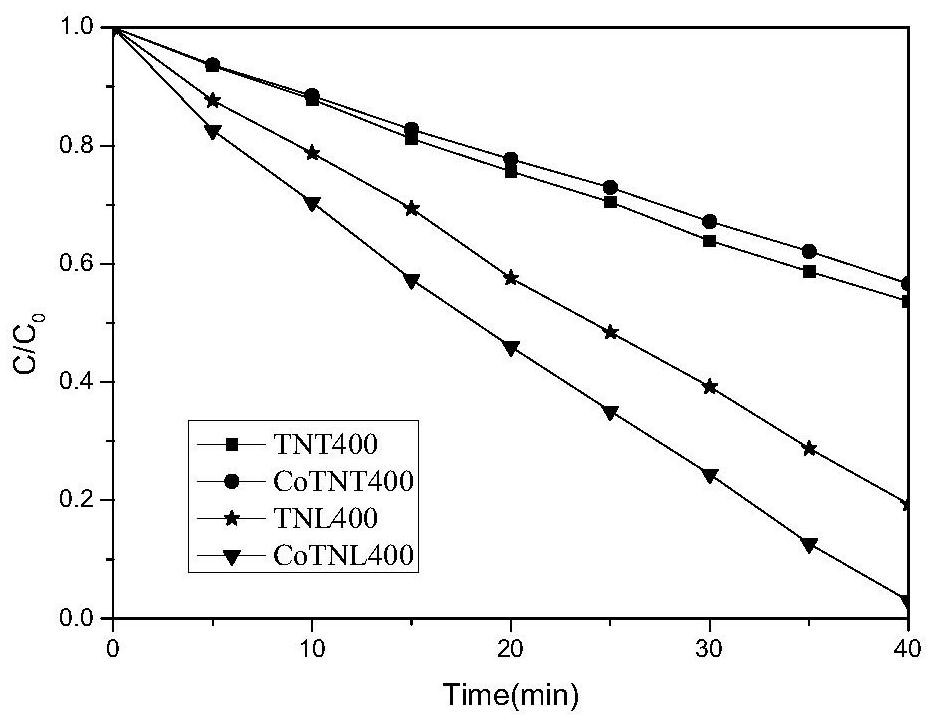

[0042] Example 3: Cobalt doped TiO 2 Application of nanotubes in dye-sensitized solar cells

[0043] (1) Preparation of cobalt doped TiO 2 Nanotube slurry: 3g cobalt doped TiO 2 The nanotube sample was placed in a mortar, then 1 mL of 10% acetylacetone in absolute ethanol was added, and ground for 30 min; then 4.5 mL of water, 0.1 mL of Triton X-100 (TritonX-100 for short) and 30% wt ( 0.9g) a mixed solution of polyethylene glycol (molecular weight 20000), grinding for 30min to obtain cobalt element doped TiO 2 Nanotube slurry;

[0044] (2) Preparation of TiO by powder coating method 2 Nanotube thin film electrode: use scotch tape to stick longitudinally on the drawn two layers of TiO 2 On both sides of the thin film FTO conductive glass, add 2mL cobalt doped TiO 2 Nanotube slurry, roll coating with a glass rod to form a film, the film area is about 0.4×0.4cm 2 ; Then place the film in a muffle furnace, raise the temperature to 500°C at a rate of 2°C / min, keep it warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com