Preparation method of amino functional magnetic silicon dioxide adsorption material

An amino-functionalized, silica technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of harsh conditions, complex operating processes, and high process conditions , to achieve the effect of fast adsorption kinetics, simplified preparation process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

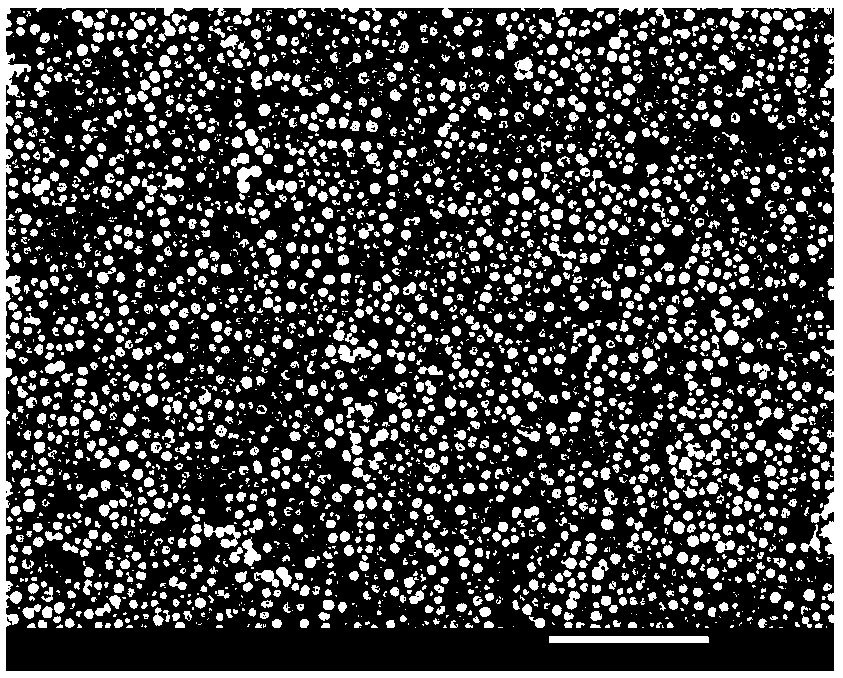

[0035] (1) 2g FeCl 3 ·6H 2 O (analytical pure) was added to 60mL of ethylene glycol (analytical pure) and stirred until completely dissolved, then 3.5g CH 3 COONa (analytical pure), vigorously stirred for 30 min, then the mixture was transferred to a polytetrafluoroethylene kettle, and hydrothermally reacted at 180° C. for 12 h. Finally, the product is magnetically separated, washed several times with deionized water until the washing liquid is clear, washed once with ethanol (analytical pure), and dried at 60°C for 12 hours in a vacuum to obtain the magnetic Fe. 3 o 4 nanoparticles.

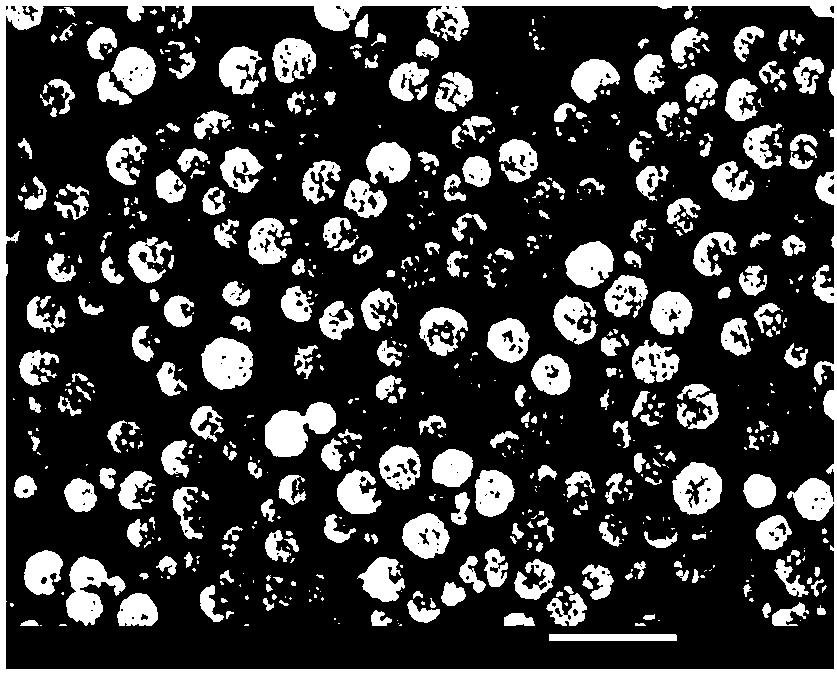

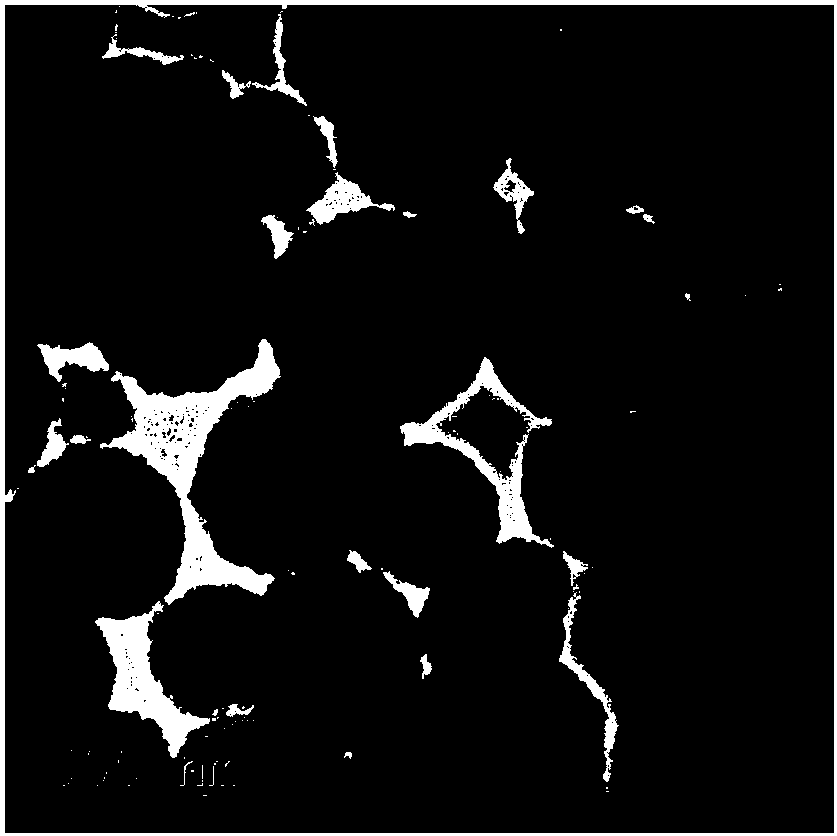

[0036] (2) Weigh the above Fe 3 o 4 Put 0.3g into the mixture of 3mL concentrated ammonia water (25-28%), 400mL ethanol (analytical pure) and 50mL distilled water, disperse under ultrasonic for 20min, then add dropwise 3mL tetraethyl orthosilicate (analytical pure), and stir the reaction After 1h, slowly add 300μL of 3-aminopropyltrimethoxysilane (97%) dropwise, continue to stir for 4h, a...

Embodiment 2

[0039] (1) 2g FeCl 3 ·6H 2 O (analytical pure) was added to 19 mL of ethylene glycol (analytical pure) and stirred until completely dissolved, then 2.4 g of CH 3 COONa (analytical grade) was vigorously stirred for 30 minutes, then the mixture was transferred to a polytetrafluoroethylene kettle, and hydrothermally reacted at 190° C. for 16 hours. Finally, the product is magnetically separated, washed several times with deionized water until the washing liquid is clear, washed once with ethanol (analytical pure), and dried at 60°C for 12 hours in a vacuum to obtain the magnetic Fe. 3 o 4 nanoparticles.

[0040] (2) Weigh the above Fe 3 o 4 Put 0.3g into a mixture of 3mL concentrated ammonia water (25-28%), 360mL ethanol (analytical pure) and 90mL distilled water, disperse under ultrasonic for 20min, then add dropwise 0.5mL tetraethyl orthosilicate (analytical pure), stir After reacting for 6 hours, slowly add 1100 μL of 3-aminopropyltriethoxysilane (99%) dropwise, continu...

Embodiment 3

[0043] (1) 2g FeCl 3 ·6H 2 O (analytical pure) was added to 74mL of ethylene glycol (analytical pure) and stirred until completely dissolved, then 3.6g CH 3 COONa (analytical pure), stirred vigorously for 30 min, then transferred the mixture to a polytetrafluoroethylene kettle, and reacted hydrothermally at 200° C. for 10 h. Finally, the product is magnetically separated, washed several times with deionized water until the washing liquid is clear, washed once with ethanol (analytical pure), and dried at 60°C for 12 hours in a vacuum to obtain the magnetic Fe. 3 o 4 nanoparticles.

[0044] (2) Weigh the above Fe 3 o 4 Put 0.3g into a mixture of 3mL concentrated ammonia water (25-28%), 405mL ethanol (analytical grade) and 45mL distilled water, disperse under ultrasonic for 20min, then add dropwise 4mL tetraethyl orthosilicate (analytical grade), and stir to react After 0.4h, slowly add 300μL of N-(aminoethyl)-γ-aminopropyltrimethoxysilane (95%) dropwise, continue to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com