Covalent organic framework compound solid phase micro-extraction fiber head and preparation method thereof

A technology of covalent organic framework and fiber extraction, which is applied in the field of analytical chemistry and food safety testing, can solve the problems of sample cross-contamination, retention, waiting for development, etc., achieve good thermal stability and solvent stability, and lower detection limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

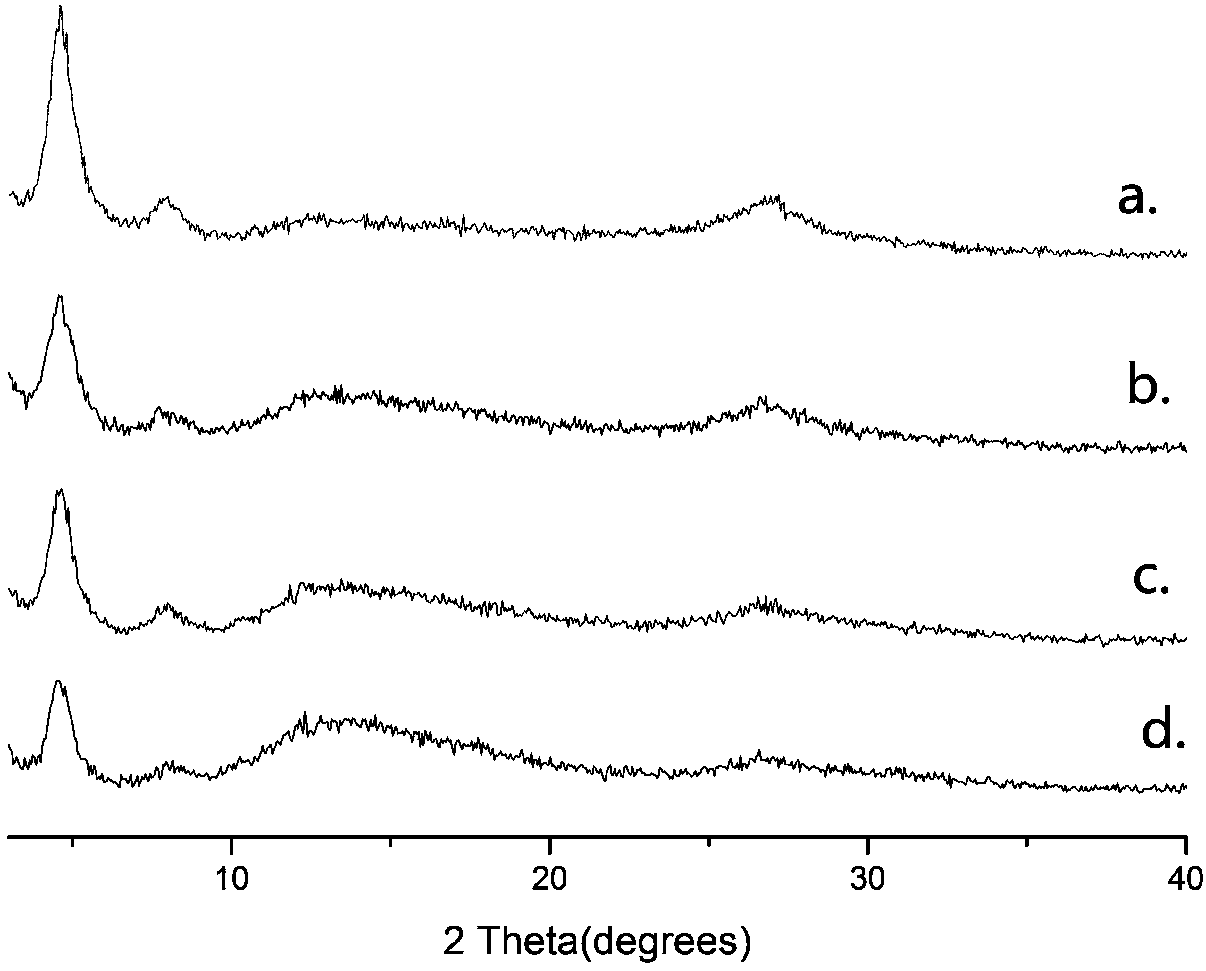

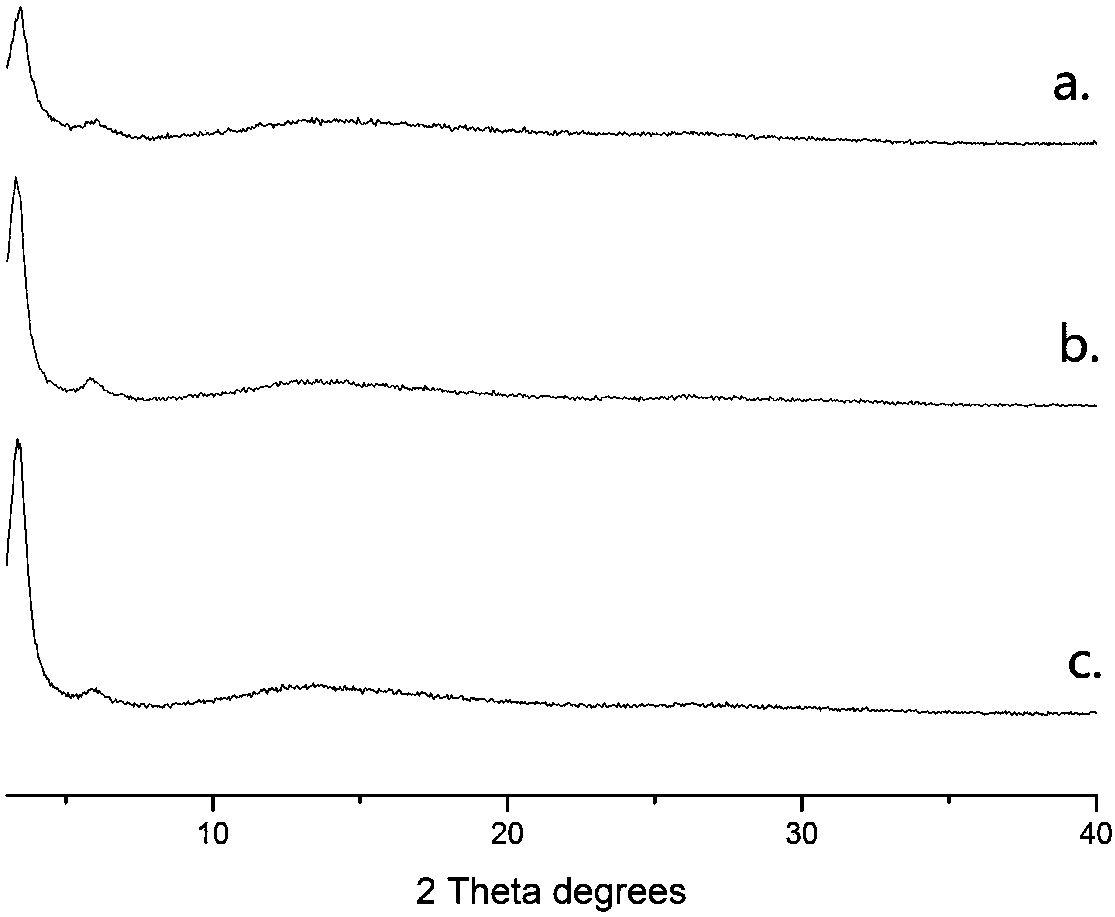

[0051] Example 1: Preparation of solid phase microextraction fiber and solid phase microextraction device with titanium wire as the base and COF coating

[0052] (1) Pretreatment of metal fiber substrate

[0053] A titanium wire with a diameter of 0.25mm and a purity of 99.7% was used as the substrate of the solid-phase microextraction fiber, which was ultrasonically treated with purified water and ethanol for 10 minutes, and dried for later use.

[0054] (2) Electrochemical anodization is performed on titanium wires using an electrochemical workstation to form titanium dioxide nanotube arrays on the titanium wires

[0055] Prepare a 0.5wt% ammonium fluoride-ethylene glycol solution containing 3% water in a small clean plastic beaker, use a platinum electrode as a counter electrode, and insert a pretreated titanium wire into the solution as a working electrode at a depth of 3 cm. The spacing is 3.5cm. The current-time curve mode was selected, and different oxidation times (1...

Embodiment 2

[0064] Example 2: Extraction and detection of 15 PAEs in water samples using COF (COF-TpBD, COF-TpPa-1) coated solid-phase microextraction fibers

[0065] (1) Standard solution preparation: PAEs-methanol mixed standard solution with a concentration of 1000mg / mL, including dimethyl phthalate (DMP), diethyl phthalate (DEP), diisobutyl phthalate ester (DIBP), di-n-butyl phthalate (DBP), bis(2-methoxy)ethyl phthalate (DMEP), bis(4-methyl-2-pentyl phthalate) ) ester (BMPP), bis(2-ethoxy)ethyl phthalate (DEEP), dipentyl phthalate (DPP), dihexyl phthalate (DHXP), phthalic acid Butylbenzyl ester (BBP), bis(2-butoxy)ethyl phthalate (DBEP), dicyclohexyl phthalate (DCHP), bis(2-ethyl) phthalate Hexyl ester (DEHP), diphenyl phthalate (DphP), and di-n-octyl phthalate (DNOP) were serially diluted to 100 mg / mL and 10 mg / mL, and used as stock solution and intermediate solution, respectively. The concentration of the working solution for the standard curve is 5 μg / mL, 10 μg / mL, 20 μg / mL, 50 ...

Embodiment 3

[0079] Example 3: Extraction and detection of 11 kinds of PAEs in vegetables using COF (COF-TpBD) coated solid-phase microextraction fiber

[0080](1) Standard solution preparation: PAEs-methanol standard solution with a concentration of 1000mg / mL, including DMP / DEP / DIBP / DBP / DMEP / BMPP / DEEP / DPP / DHXP / BBP / DBEP / DCHP / DEHP / DphP / DNOP gradient Dilute to 100mg / mL, 10mg / mL, respectively as stock solution and intermediate solution. The concentration of the working solution for the standard curve is 5 μg / mL, 10 μg / mL, 20 μg / mL, 50 μg / mL, 100 μg / mL, 200 μg / mL, 500 μg / mL, 1000 μg / mL, ready for use.

[0081] (2) Pretreatment of samples to be tested

[0082] After 3 g of vegetables were fully crushed, 20 μL of 5 ppm standard working solution was added and mixed evenly, and a certain proportion of water was added to be fully ultrasonicated, oscillated, and directly put into the sample bottle of the SPME device prepared in Example 1.

[0083] (3) The specific steps of headspace extraction are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com