A kind of two-component modified waterborne polyurethane flame retardant coating glue and its preparation method

A water-based polyurethane, two-component modification technology, applied in the direction of polyurea/polyurethane coatings, coatings, fireproof coatings, etc., can solve the problems of poor mechanical properties, foaming and falling off, not environmental protection, etc., to achieve thermal stability and Improved flame retardant performance, improved flame retardant performance and mechanical properties, good rub resistance and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

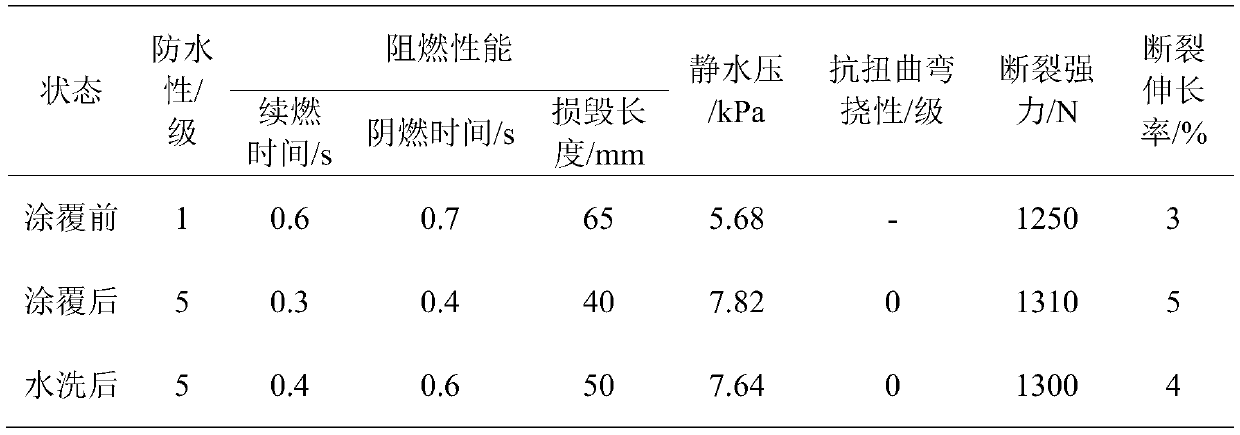

Embodiment 1

[0044] Take 10g of montmorillonite and 120mL of an aqueous solution with a mass fraction of 50% ethanol and mix them. After ultrasonic dispersion at room temperature for 0.5h, heat to 75°C and add 4g of dodecylbishydroxyethylmethylammonium chloride to the reaction system. , after reacting for 6 hours, cooling, centrifugal precipitation, repeated washing with absolute ethanol, and vacuum drying to obtain modified montmorillonite.

[0045] React 50g of HDI and 371g of polybutadiene diol with a molecular weight of 3000 at 75°C for 2.5h, then lower the temperature to 55°C, dissolve 3.2g of 1,4-butanediol in 50g of acetone and add dropwise for 20min, then continue After reacting for 1.5 h, then raising the temperature to 70° C., adding a mixed solution of 6 g of modified montmorillonite and 60 mL of N-methylpyrrolidone to react for 1.5 h to obtain a polyurethane prepolymer.

[0046] Add 550g of acetone to the modified polyurethane prepolymer to reduce the viscosity of the emulsion ...

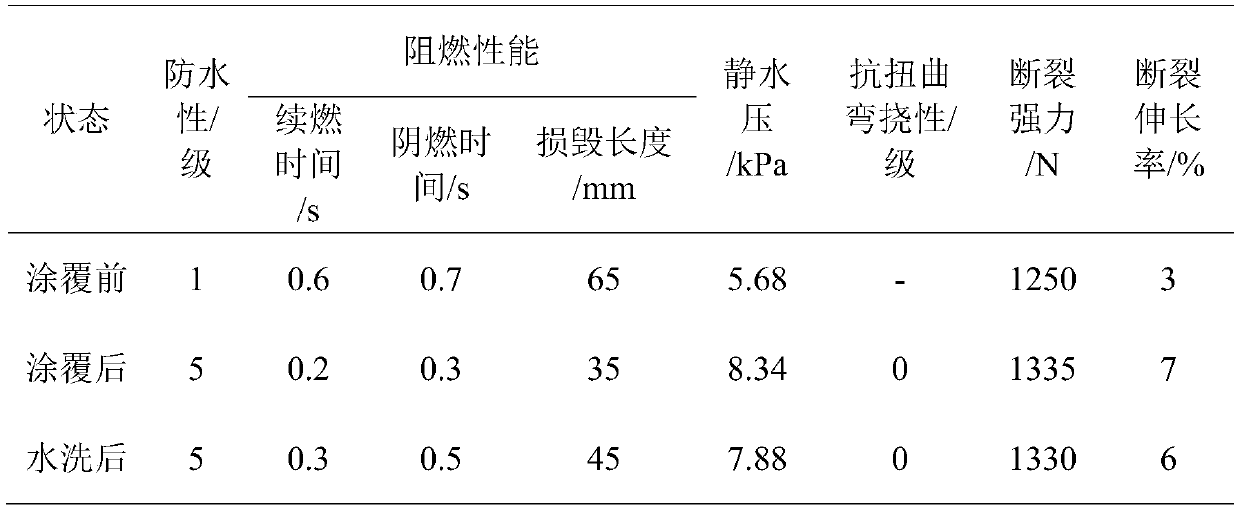

Embodiment 2

[0052] Mix 10g of montmorillonite with 120mL of 50% ethanol aqueous solution, ultrasonically disperse at room temperature for 1h, heat to 70°C, add 3g of hexadecyl dihydroxyethylammonium bromide to the reaction system, and react for 8h Finally, cooling, centrifugal precipitation, repeated washing with absolute ethanol, and vacuum drying to obtain modified montmorillonite;

[0053] React 50g of IPDI and 225g of polycaprolactone diol with a molecular weight of 2000 at 80°C for 3h, then lower the temperature to 50°C, dissolve 4g of 2,3-butanediol in 60g of acetone and add dropwise for 30min, then continue the reaction for 2h, then After raising the temperature to 75°C, add a mixed solution of 9 g of modified montmorillonite and 80 mL of N-methylpyrrolidone to react for 1.5 h to obtain a polyurethane prepolymer;

[0054] Add 350g of acetone to the modified polyurethane prepolymer to reduce the viscosity of the emulsion into drops, then add 16.2g of 50% 1,4-butanediol-2-sodium sulf...

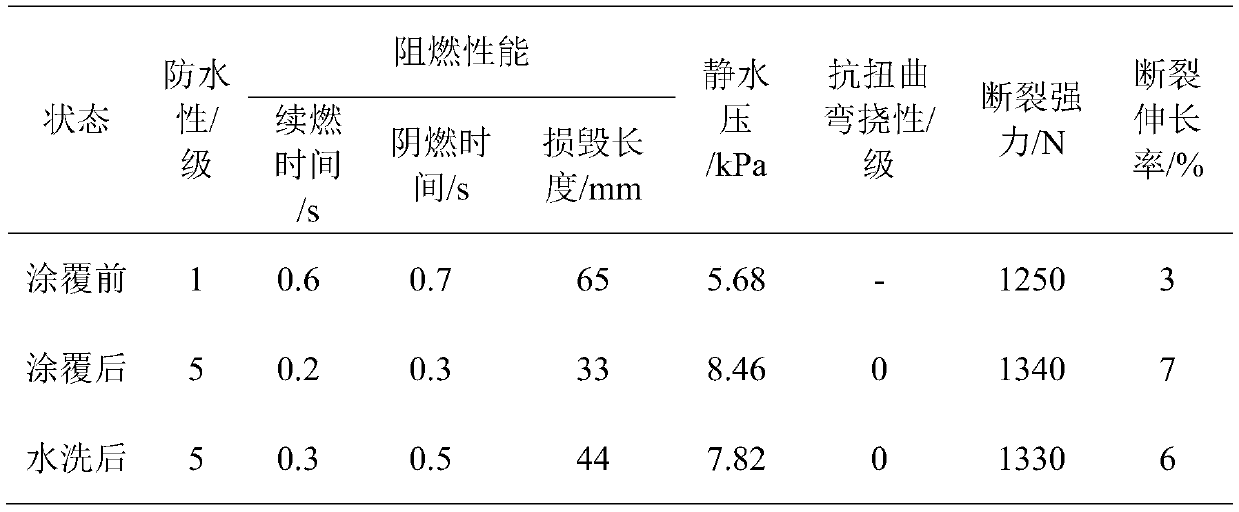

Embodiment 3

[0060] Mix 20g of montmorillonite and 120mL of 50% ethanol aqueous solution, ultrasonically disperse at room temperature for 0.5h, heat to 80°C, add 5g of dihydroxypropyl dimethyl dodecyl chloride to the reaction system ammonium, after reacting for 7 hours, cooling, centrifugal precipitation, repeated washing with absolute ethanol, and vacuum drying to obtain modified montmorillonite;

[0061] React 50g of 1,4-cyclohexane diisocyanate and 540g of polyadipate-1,4-butylene adipate diol with a molecular weight of 3000 at 75°C for 2 hours, then lower the temperature to 60°C, and 4.1g of 1,3 -Propylene glycol was dissolved in 60g of acetone and added dropwise for 15min, and then continued to react for 1.5h, then added a mixed solution of 12g of modified montmorillonite and 100mL of N-methylpyrrolidone to react for 2h after raising the temperature to 65°C to obtain a modified polyurethane prepolymer body;

[0062] Add 800g of acetone to the modified polyurethane prepolymer to reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com