Sheep manure wrapping technology

A sheep manure, wrapping technology, applied in the direction of layered/coated fertilizer, application, organic fertilizer, etc., can solve the problems of hindering the normal life activities of crops, incomplete release of nutrients, incomplete decomposing of sheep manure, etc. The effect of breeding of miscellaneous bacteria and pathogenic microorganisms, improving population structure, improving soil permeability and the ability to retain water and fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

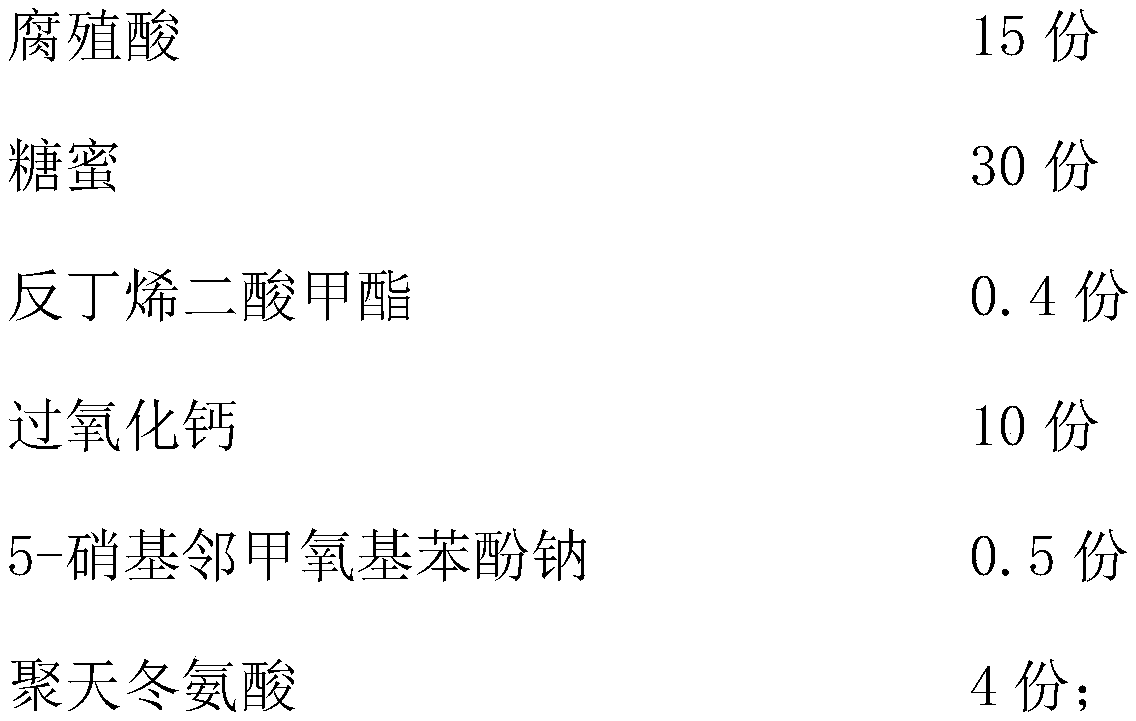

Embodiment 1

[0025] Step 1: Add corn stalk powder with a water content of ≤20% to fresh sheep manure, and adjust the dry matter content of the mixture to 30-35%;

[0026] Step 2: Grind until the particle size of the mixture is 40 mesh, and mix in 6%wt special additives, and then use 160uW / cm 2 Intensity of ultraviolet radiation for 20 minutes to obtain the fermentation substrate;

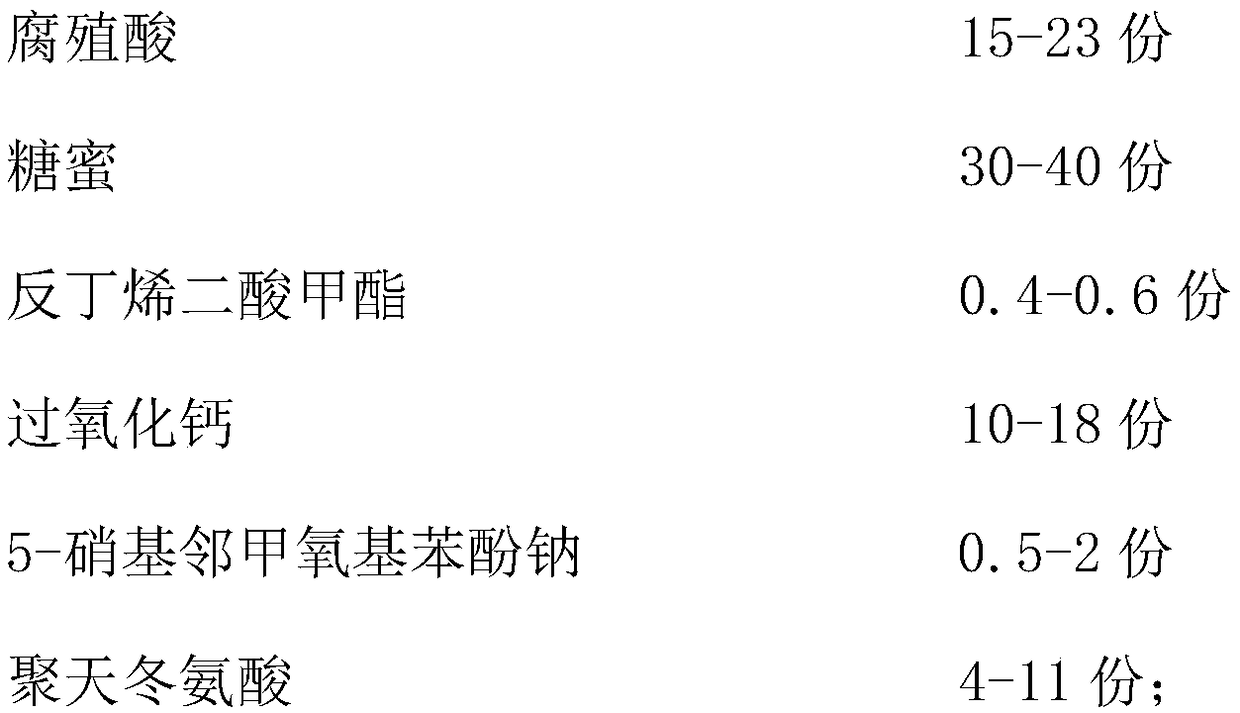

[0027] Wherein, the special additive includes the following components in parts by weight:

[0028]

[0029] Step 3: Inoculate bifidobacterium, yeast, propionibacterium, and lactobacillus in the wort medium at a weight ratio of 1:2:1.5:1.9, train them for 10 days at 36°C under nitrogen, and then concentrate Refining to obtain a microbial starter, adding 10%wt microbial starter to the fermentation substrate, stirring at a rate of 90r / min for 30min, compacting, and using a silage wrapper and a polyethylene film to wrap the film tightly, and the packing density is 700kg / m 3 , to obtain a cylindrical anaerobic...

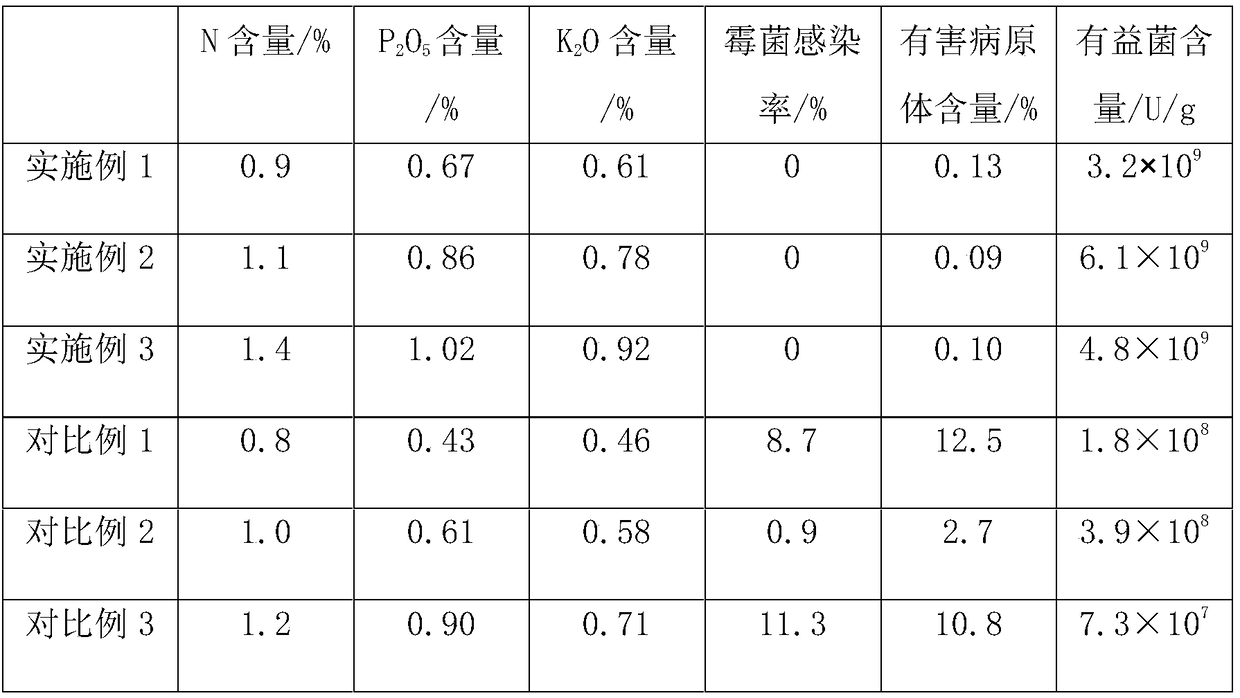

Embodiment 2

[0032] The operation is the same as in Example 1, wherein the auxiliary material in step one is rice bran, and the dry matter content is 33%; parts, 35 parts, 0.5 parts, 14 parts, 1.25 parts, 7.5 parts, the ultraviolet radiation intensity and time are 180uW / cm 2 , 25min; in step 3, the weight ratio and mass percentage of each component bacterium are 1.1:2.5:1.6:2 and 12.5%wt successively, the stirring speed and length are successively 100r / min, 35min, and the plastic film is polypropylene; the temperature in step 4 The temperature is 34°C, the diameter of the cylindrical anaerobic fermentation system is 1.0m, the height is 1.4m, and the fermentation is 55d.

Embodiment 3

[0034] The operation is the same as in Example 1, wherein the auxiliary material in step 1 is peanut shell powder, and the dry matter content is 35%; in step 2, the crushing fineness is 70 mesh, and the mass percentage of special additives and the parts by weight of each component are sequentially 10%wt And 23 parts, 40 parts, 0.6 parts, 18 parts, 2 parts, 11 parts, the ultraviolet radiation intensity and time are 200uW / cm 2 , 30min; in step 3, the weight ratio and mass percentage of each component bacterium are 1.2:3:1.7:2.1 and 15%wt successively, the stirring speed and length are successively 110r / min, 40min, and the plastic film is polypropylene; the temperature in step 4 The temperature is 38°C, the diameter of the cylindrical anaerobic fermentation system is 1.2m, the height is 1.5m, and the fermentation is 60d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com