Power distribution box case material and preparation method thereof

A technology of shell material and distribution box, applied in the field of distribution box shell material and its preparation, can solve the problems of insufficient flame retardancy of the distribution box shell material, small scope of popularization and application, affecting the work of components, etc., so as to improve the anti-ultraviolet ability, enhanced abrasion resistance, enhanced crosslinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

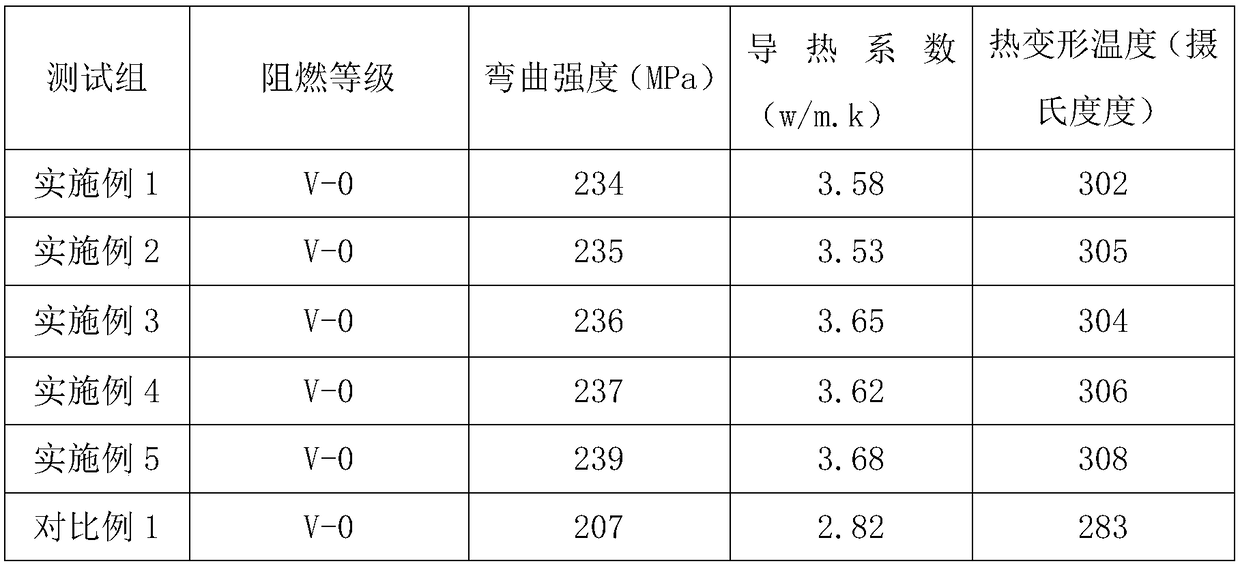

Examples

Embodiment 1

[0030] A distribution box shell material, comprising the following raw materials in parts by weight:

[0031] 35 parts of polycarbonate, 20 parts of polyphenylene ether resin, 6 parts of ethylene zincene copolymer, 3 parts of dioctyl phthalate, 14 parts of acrylic resin, 12 parts of kaolin, 5 parts of dolomite, 4 parts of aluminum tripolyphosphate 7 parts of silicon carbide, 6 parts of modified carbon nanotubes, 5 parts of nano-titanium dioxide, 5 parts of nano-zinc oxide, 2 parts of white carbon black, 1 part of polyethylene wax, 0.6 parts of silane coupling agent and 1.2 parts of antioxidant.

[0032] The preparation method of modified carbon nanotubes is as follows:

[0033] (S1) Add carbon nanotubes to chlorosulfonic acid, heat to 80 degrees Celsius to swell for 1 hour, cool and filter, wash the filtrate with deionized water until the pH is neutral, anneal at 1800 degrees Celsius for 3 hours in an argon atmosphere, and cool to After room temperature, the swollen carbon na...

Embodiment 2

[0045] A distribution box shell material, comprising the following raw materials in parts by weight:

[0046] 50 parts of polycarbonate, 28 parts of polyphenylene ether resin, 12 parts of ethylene zincene copolymer, 8 parts of dioctyl phthalate, 20 parts of acrylic resin, 18 parts of kaolin, 13 parts of dolomite, 10 parts of aluminum tripolyphosphate 15 parts of silicon carbide, 12 parts of modified carbon nanotubes, 10 parts of nano-titanium dioxide, 10 parts of nano-zinc oxide, 4 parts of white carbon black, 4 parts of polyethylene wax, 1.5 parts of silane coupling agent and 1.8 parts of antioxidant.

[0047] The preparation method of modified carbon nanotubes is as follows:

[0048] (S1) Add carbon nanotubes to chlorosulfonic acid, heat to 100 degrees Celsius to swell for 3 hours, cool and filter, wash the filtrate with deionized water until the pH is neutral, anneal in 2000 degrees Celsius for 5 hours in an argon atmosphere, and cool to After room temperature, the swollen...

Embodiment 3

[0060] A distribution box shell material, comprising the following raw materials in parts by weight:

[0061] 40 parts of polycarbonate, 22 parts of polyphenylene ether resin, 8 parts of ethylene zincene copolymer, 4 parts of dioctyl phthalate, 16 parts of acrylic resin, 14 parts of kaolin, 7 parts of dolomite, 5 parts of aluminum tripolyphosphate 9 parts of silicon carbide, 8 parts of modified carbon nanotubes, 6 parts of nano-titanium dioxide, 6 parts of nano-zinc oxide, 2.5 parts of white carbon black, 2 parts of polyethylene wax, 0.8 parts of silane coupling agent and 1.4 parts of antioxidant.

[0062] The preparation method of modified carbon nanotubes is as follows:

[0063] (S1) Add carbon nanotubes to chlorosulfonic acid, heat to 88 degrees Celsius to swell for 2 hours, cool and filter, wash the filtrate with deionized water until the pH is neutral, anneal at 1900 degrees Celsius for 4 hours in an argon atmosphere, and cool to After room temperature, the swollen carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com