Method for preparing instant-soluble anionic high molecular weight polyacrylamide by two-step method

A polyacrylamide and high molecular weight technology is applied in the field of two-step preparation of instant anionic high molecular weight polyacrylamide. The effect of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

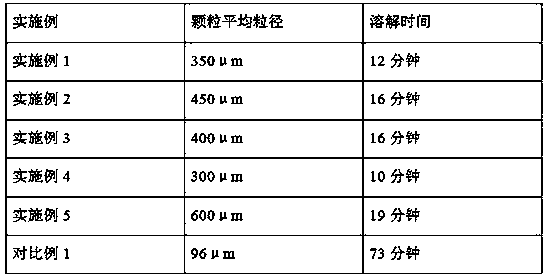

Examples

Embodiment 1

[0029] Add 300 g of cyclohexane into a 1 L four-neck flask, add 1.15 g of sorbitan monostearate and 1 g of sucrose fatty acid ester with an HLB value of 3, and heat until dissolved. Dissolve 95g of acrylamide and 0.8g of potassium persulfate in 200g of water in a beaker, and add them to a four-necked flask under a nitrogen atmosphere; add a hydrolyzing agent to the four-necked flask, and the hydrolyzing agent is a hydrogen hydroxide with a mass ratio of 5:1. A mixture of sodium and sodium carbonate, the amount of the hydrolyzing agent is 15% of the mass of the acrylamide monomer. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heating to 70°C, reacting for 2 hours, raising the temperature to 75°C for 1 hour, and obtaining primary particles. The primary particles were hydrolyzed, the hydrolysis temperature was 80°C, and the hydrolysis time was 8 hours. In another flask, add 20g of ethanol and 100g of water to form a mixed solution. Th...

Embodiment 2

[0031] Add 300g of n-hexane into a 1L four-neck flask, add 2g of hydrophobic nano-silica and 1g of diethylene glycol fatty acid ester, and heat until dissolved. Use a beaker to dissolve 95g of acrylamide and 0.8g of sodium persulfate in 200g of water, and add them to a four-necked flask under a nitrogen atmosphere; add a hydrolyzing agent to the four-necked flask, and the hydrolyzing agent is hydrogen peroxide with a mass ratio of 5:2. The mixture of sodium and sodium carbonate, the consumption of described hydrolysis agent is 18% of the mass of acrylamide monomer. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heating to 70°C, reacting for 2 hours, raising the temperature to 75°C for 1 hour, and obtaining primary particles. The primary particles were hydrolyzed, the hydrolysis temperature was 85°C, and the hydrolysis time was 7 hours. In another flask, add 6g of ethanol and 50g of water to form a mixed solution. The alcohol-water m...

Embodiment 3

[0033]Add 300 g of toluene into a 1 L four-neck flask, add 3 g of glyceryl monostearate, and heat until dissolved. Use a beaker to dissolve 95g of acrylamide and 0.8g of azobisisobutylimidazoline hydrochloride in 200g of water, and add them to a four-necked flask under a nitrogen atmosphere; add a hydrolyzing agent to the four-necked flask, and the hydrolyzing agent is A mixture of sodium hydroxide and sodium carbonate at a ratio of 5:3, the amount of the hydrolyzing agent is 20% of the mass of the acrylamide monomer. Rotate at 400 rpm, blow nitrogen, stir for 30 minutes, and keep the temperature at 40°C. Heat to 60°C, react for 2 hours, raise the temperature to 75°C and keep it for 1 hour to obtain primary particles. The primary particles were hydrolyzed, the hydrolysis temperature was 90°C, and the hydrolysis time was 6 hours. In another flask, add 10g of isopropanol and 100g of water to form a mixed solution. The alcohol-water mixed solution was added dropwise into the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com