Algin lyase having heat recovery characteristic and application of algin lyase

A alginate lyase and heat recovery technology, applied in the field of alginate lyase, can solve the problems of unreachable industrial application, poor heat stability and heat recovery, easy inactivation, etc., and achieve good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Sequence analysis of alginate lyase AlyL05

[0032] Alginate lyase AlyL05 of the present invention is derived from alginic vibrio ( Vibrio alginolyticus), the strain was purchased from the China Marine Microorganism Culture Collection (MCCC), and the strain number is MCCC 1D00120. The entire genome of the strain was scanned and sequenced by pyrosequencing technology, which was completed by Beijing Berry Hekang Company. Using the analysis of the Carbohydrate-Active enZYmes Database (CAZy, http: / / www.cazy.org / ), a predicted alginate lyase sequence of the Polysaccharide Lyase family 7 (PL-7) family was obtained, named alyL05 . sequence alyL05 Contains a 1,002-base sequence encoding a 333-amino acid sequence; the sequence was obtained using the National Center for Biotechnology Information (NCBI, https: / / www.ncbi.nlm.nih.gov / ) Conserved domain analysis Conserved domain (CDD, https: / / www.ncbi.nlm.nih.gov / cdd) and Multiple Sequence Alignment Basic Loc...

Embodiment 2

[0033] Example 2 Gene cloning and recombinant expression of alginate lyase AlyL05

[0034] With the marine bacterial strain that buys in embodiment 1 Vibrio alginolyticus MCCC 1D00120 is cultured in a special medium for marine bacteria (2216E medium), shaken at 180 rpm in a 20°C incubator for 10-12 hours, until the cell density is OD 600 =1.0; the whole genome of the strain was extracted using a genome extraction kit (purchased from Dalian Bao Biology Co., Ltd.). restriction endonuclease Nco I and xho I (purchased from Dalian Bao Biological Co., Ltd.) is the enzyme cutting site and the protection base of the enzyme cutting site is designed, the stop codon TAA is removed, and the recombinant primers are designed as follows (the underline is the restriction endonuclease site, and the italic is the restriction endonuclease site) Dicer protected bases):

[0035] Forward primer: SEQ ID NO.3: PalyL5EF:

[0036] 5'- CATG CCATGG GTATGATCACGGCCACGAAAGG-3’ ( Nco I)

[0...

Embodiment 3

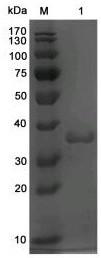

[0043] Example 3 Fermentation process and purification preparation method of alginate lyase AlyL05

[0044] The Escherichia coli BL21(DE3) / pET22b-alyL05 constructed and stored at -80°C in Example 2 was streaked on the LB solid plate, and after culturing at 37°C for 16 hours, single clones were picked; the single clones were transferred to cells containing 50 μg / mL ampicillin in LB liquid medium (500 mL Erlenmeyer flask loaded with 50 mL liquid medium), cultured in a shaker at 37°C at 180 rpm to OD 600 =0.6. The 5 L fermenter was loaded with 60% (3 L) Terrific Broth (TB) medium, and sterilized in advance; 50 μg / mL ampicillin was added to the fermenter, and the cultured bacteria in the Erlenmeyer flask The solution was inoculated into a 5 L fermenter according to the inoculum amount of 2%. Adjust the initial ventilation rate to 50 L / h, the initial rotation speed to 350 rpm, the temperature at 37°C, and the dissolved oxygen at 15-40%; when the bacteria grow to OD 600 When =5.0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com