A modified nickel-cobalt-aluminum ternary positive electrode material and preparation method thereof

A cathode material, nickel-cobalt-aluminum technology, applied in the field of modified nickel-cobalt-aluminum ternary cathode material and its preparation, can solve the problem of unfavorable nickel-cobalt-aluminum ternary cathode material rate performance and cycle life, difficult to meet market demand and industrialization Production, easy absorption of moisture and carbon dioxide, etc., to achieve cycle stability, high energy density and bulk density, low requirements for equipment and reaction conditions, and improved stability and electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

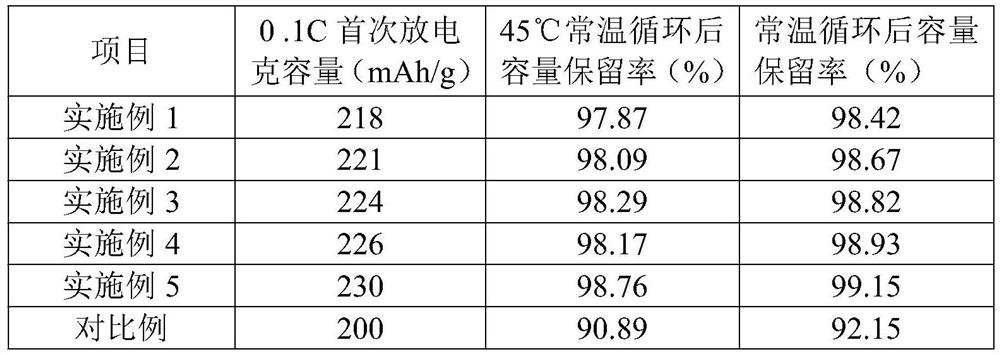

Examples

Embodiment 1

[0024] A method for preparing a modified nickel-cobalt-aluminum ternary positive electrode material, comprising the steps of:

[0025] 1) Add cobalt sulfate, nickel citrate, lithium acetate and aluminum nitrate to citric acid to make 4mol L -1 mixed salt solution, then add ammonia water, adjust the pH of the solution to 10, and then spray dry the solution, and finally obtain precursor particles that are uniformly mixed at the molecular level; Keep warm for 3 hours, then heat up to 700°C and sinter for 12 hours, cool naturally to room temperature, grind the product, and pass through a 200-mesh sieve to obtain a nickel-cobalt-aluminum ternary positive electrode material; the cobalt sulfate, nickel citrate, lithium acetate, nitric acid The molar ratio of aluminum is 0.3:2:1.7:0.04;

[0026] 2) Disperse 20 g of fluorinated graphene and 1 g of 3-chloropropylmethyldimethoxysilane in 50 g of ethanol, stir for 1 hour, then add 1 g of tetrakis(dimethylamino)titanium, and stir at 40°C ...

Embodiment 2

[0031] A method for preparing a modified nickel-cobalt-aluminum ternary positive electrode material, comprising the steps of:

[0032] 1) Add cobalt nitrate, lithium carbonate, nickel acetate and aluminum nitrate to citric acid to make 4.3mol L -1 mixed salt solution, and then add ammonia water to adjust the pH of the solution to 11, and then spray-dry the solution to finally obtain precursor particles that are uniformly mixed at the molecular level; Keep warm for 3.5 hours, then heat up to 730°C and sinter for 13 hours, cool naturally to room temperature, grind the product, and pass through a 250-mesh sieve to obtain a nickel-cobalt-aluminum ternary positive electrode material; the cobalt nitrate, lithium carbonate, nickel acetate, aluminum nitrate The molar ratio is 0.3:2:1.7:0.04.

[0033] 2) Disperse 23 g of fluorinated graphene and 1 g of 3-chloropropylmethyldimethoxysilane in 65 g of ethanol, stir for 1.2 hours, then add 1.5 g of tetrakis(dimethylamino)titanium to it, a...

Embodiment 3

[0038] A method for preparing a modified nickel-cobalt-aluminum ternary positive electrode material, comprising the steps of:

[0039] 1) Add cobalt chloride, lithium oxalate, nickel chloride, and aluminum nitrate to citric acid to make 4.5mol L -1mixed salt solution, then add ammonia water, adjust the pH of the solution to 10, and then spray-dry the solution to finally obtain precursor particles that are uniformly mixed at the molecular level; Keep warm for 4 hours, then heat up to 750°C and sinter for 13.5 hours, cool naturally to room temperature, grind the product, and pass through a 300-mesh sieve to obtain a nickel-cobalt-aluminum ternary positive electrode material; the cobalt chloride, lithium oxalate, nickel chloride, The molar ratio of aluminum nitrate is 0.3:2:1.7:0.04.

[0040] 2) Disperse 26 g of fluorinated graphene and 1 g of 3-chloropropylmethyldimethoxysilane in 85 g of ethanol, stir for 1.5 hours, then add 2 g of tetrakis(dimethylamino)titanium, and stir at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com