Multi-layer composite photovoltaic packaging adhesive film resistant to PID (potential induced degradation) as well as preparation method and application

A potential-induced decay, multi-layer composite technology, applied in photovoltaic power generation, thin film/sheet adhesives, circuits, etc., can solve the problem of unsatisfactory anti-PID effect of double-sided cell modules, and unfavorable cost reduction of photovoltaic modules. , The problem of high price of polyolefin resin raw materials, to achieve the effect of low water vapor transmission rate, enhanced anti-PID performance, and improved anti-PID performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

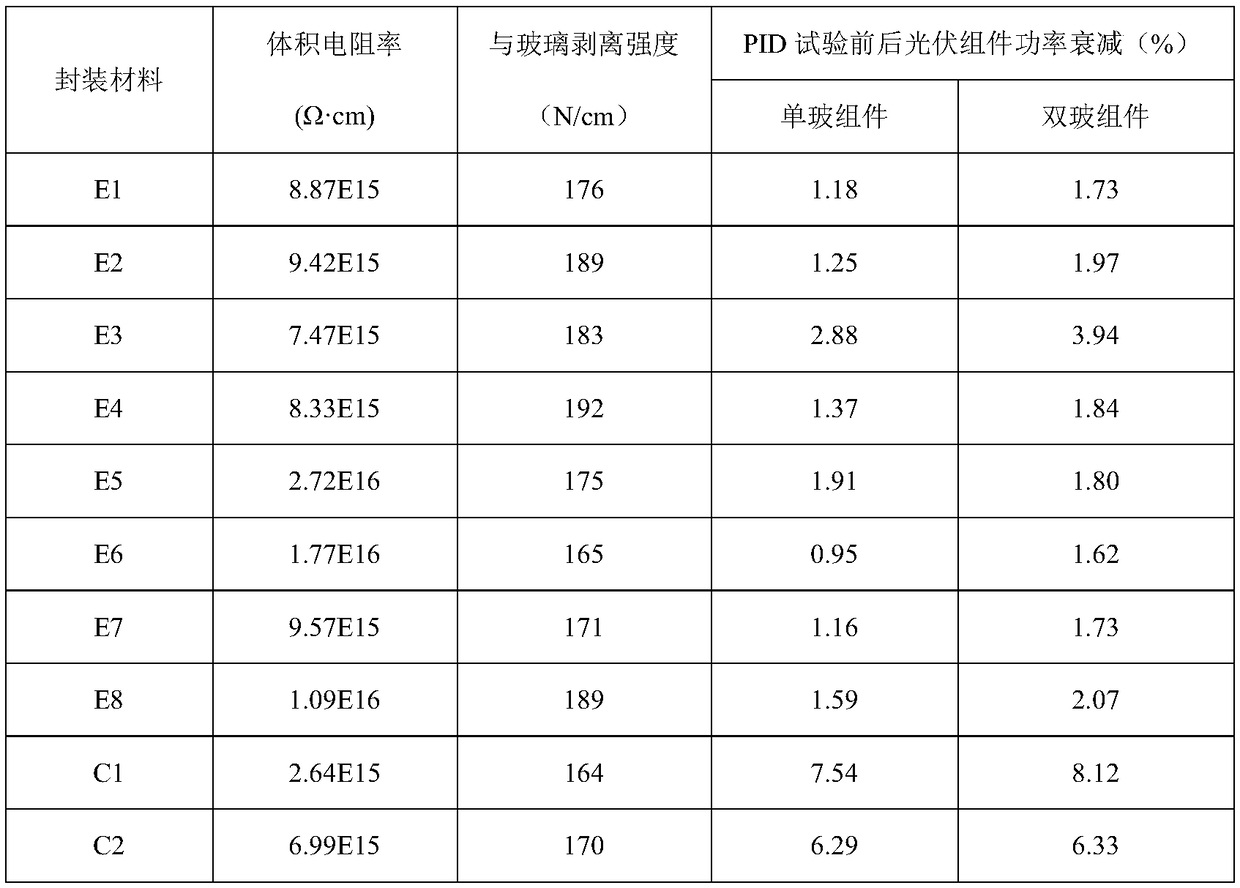

Examples

Embodiment 1

[0030] This embodiment provides a packaging material with anti-PID performance.

[0031] Adhesive layer: in terms of mass fraction, get 100 parts of VA (vinyl acetate) ethylene-vinyl acetate copolymer with a mass content of 21%, add 0.8 part of tert-butyl peroxyisopropyl carbonate, 0.8 part of triethylenedi Alcohol dimethacrylate, 0.1 part of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 part of vinyltriethoxysilane, 0.1 part of bis(2,2,6,6-tetramethyl- 4-piperidinyl) sebacate.

[0032] Barrier layer: by mass fraction, take 100 parts of ethylene-octene copolymer, 5 parts of polyethylene oxide, 0.5 part of pentaerythritol tetraacrylate, 0.1 part of 2,5-dimethyl 2,5- Bis(tert-butylperoxy)hexane, 0.1 part of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 part of vinyltriethoxysilane, 0.1 part of bis(2,2,6,6- Tetramethyl-4-piperidinyl) sebacate.

[0033] After mixing the above-mentioned resin and additive compositions of the bonding layer and the barrier layer, they are fed into different e...

Embodiment 2

[0037] This embodiment provides a packaging material with anti-PID performance.

[0038] Adhesive layer: in terms of mass fraction, get 100 parts of VA (vinyl acetate) mass content as 26% ethylene-vinyl acetate copolymer, add 0.8 parts of tert-butyl peroxyisopropyl carbonate, 10 parts of ethoxylated pentaerythritol Tetraacrylate, 0.4 parts of 2-(2'-hydroxy-3',5'-dipentylphenyl)benzotriazole, 3 parts of aminopropyltriisopropoxysilane, 1 part of bis(2,2 ,6,6-Tetramethyl-4-piperidinyl) sebacate.

[0039] Barrier layer: in terms of mass fraction, get 100 parts of ethylene-octene copolymer grafted maleic anhydride (grafting rate 5%), 5 parts of polyether ester amide, 0.5 part of triethylene glycol dimethacrylic acid ester, 0.1 part of 2,5-dimethyl 2,5-bis(tert-butylperoxy)hexane, 0.1 part of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 part of aminopropyltris Isopropoxysilane, 0.5 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate.

[0040] The film is formed by multi-layer co-e...

Embodiment 3

[0044] This embodiment provides a packaging material with anti-PID performance.

[0045] Adhesive layer 1: In terms of mass fraction, take 100 parts of ethylene-vinyl acetate copolymer with a mass content of VA (vinyl acetate) of 12%, add 1 part of 2,5-dimethyl 2,5-bis( tert-butylperoxy)hexane, 5 parts of ethoxylated trimethylolpropane triacrylate, 1 part of aminopropyltrimethoxysilane, 0.1 part of 2-hydroxy-4-methoxybenzophenone, 0.1 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate.

[0046] Barrier layer: in terms of mass fraction, get 100 parts of ethylene-butene copolymer grafted vinyltrimethoxysilane (grafting rate 20%), 5 parts of methoxy polyethanol methacrylate copolymer, 0.5 Parts of ethoxylated trimethylolpropane triacrylate, 0.1 parts of 2,5-dimethyl 2,5-bis(tert-butylperoxy)hexane, 0.1 parts of 2-hydroxy-4-methoxydi Benzophenone, 0.2 parts of aminopropyltrimethoxysilane, 0.1 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate.

[0047] Adhesive layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com