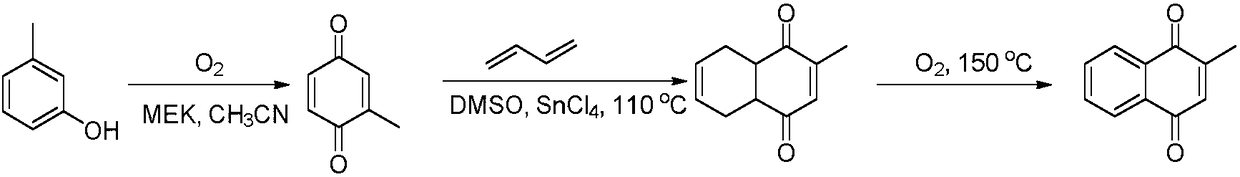

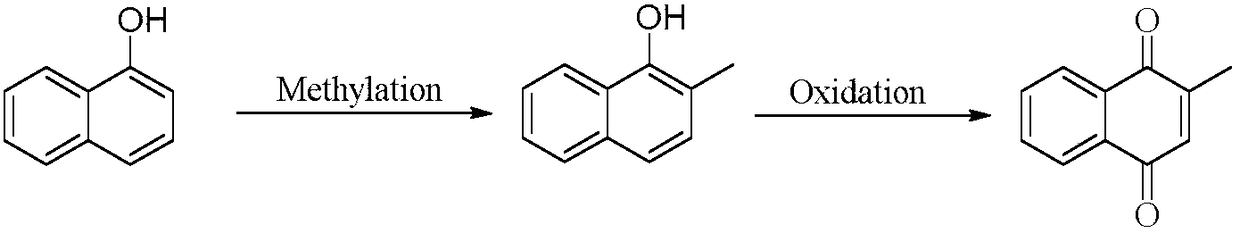

Preparation method for 2-methyl-1,4-naphthoquinone

A technology of methyl and naphthoquinone, which is applied in the field of preparation of 2-methyl-1,4-naphthoquinone, can solve the problem of low yield of 2-methyl-1-naphthol, low selectivity of oxidation reaction, unfavorable industrialization Production and other issues, to achieve the effects of environmental protection and green production, high reaction selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the preparation of 2-methyl-1,4-naphthoquinone

[0047] Add 200 g of toluene to a 500 ml four-necked flask connected with a stirring, thermometer, distillation device and constant pressure dropping funnel, heat to an internal temperature of 90-95°C, and drop 19.5 g (0.1 mole) of phthalate Dimethyl formate, 14.0 g (0.11 mole) of methyl 3-cyanobutyrate, 30 g (0.15 mole) of 27% sodium methoxide in methanol, while distilling off methanol, dropwise, and stirred at 100°C for 3 hours. Cool to 20-25°C, add 20 grams of 20% sodium hydroxide aqueous solution, stir and react at 20-30°C for 3 hours; connect the tail gas absorption device with lye, then add 30% hydrochloric acid to the reaction bottle to adjust the pH value 2.0-2.5, 60 ° C stirring reaction for 3 hours, decarboxylation dehydrocyanation; layered, the water layer was extracted with toluene 3 times, 50 grams each. The organic phases were combined, and the toluene was recovered by distillation to obtain 15...

Embodiment 2- Embodiment 4

[0050] 13 C NMR (100MHz, DMSO): δ = 16.8, 126.3, 126.2, 132.5, 132.1, 133.2, 133.9, 135.9, 148.8, 185.6, 185.8. Example 2-Example 4: Preparation of 2-methyl-1,4-naphthoquinone

[0051] As described in Example 1, the difference is that the raw materials, strong base, and solvent are changed, as shown in Table 1.

[0052] Table 1

[0053]

Embodiment 5

[0054] Embodiment 5: Preparation of 2-methyl-1,4-naphthoquinone

[0055] In a 500 ml four-necked flask connected with stirring, a thermometer, a distillation device and a constant pressure dropping funnel, add 200 grams of toluene and 17.0 grams of potassium tert-butoxide (0.15 moles), and heat to an internal temperature between 100-105 ° C. Add dropwise a mixed solution of 27.8 g (0.1 mole) of di-tert-butyl phthalate and 20.0 g (0.12 mole) of tert-butyl 3-cyanobutyrate, while distilling off tert-butanol, dropwise, and stir at 100°C for 3 hours . Cool to 20-25°C, add 20g of 20% sodium hydroxide aqueous solution, stir and react at 20-30°C for 3 hours; connect the tail gas absorption device with lye, then add 30% hydrochloric acid into the reaction bottle to adjust the pH value 2.0-2.5, 60 ° C stirring reaction for 3 hours; separate layers, the water layer was extracted with toluene 3 times, 50 grams each. The organic phases were combined, and the toluene was recovered by dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com