Composite material containing graphene/resin/carbon fiber modified electric heating layer, its preparation method and application

A technology of fiber composite materials and composite materials, applied in the field of electrothermal deicing, can solve the problems of inability to ensure the uniform combination of graphene and resin, reduce the electrical conductivity and thermal conductivity of graphene paper, and be unfavorable for the weight loss of aviation structural materials, etc., to achieve Ease of continuous automatic production, avoiding the introduction of defects, and the effect of free control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

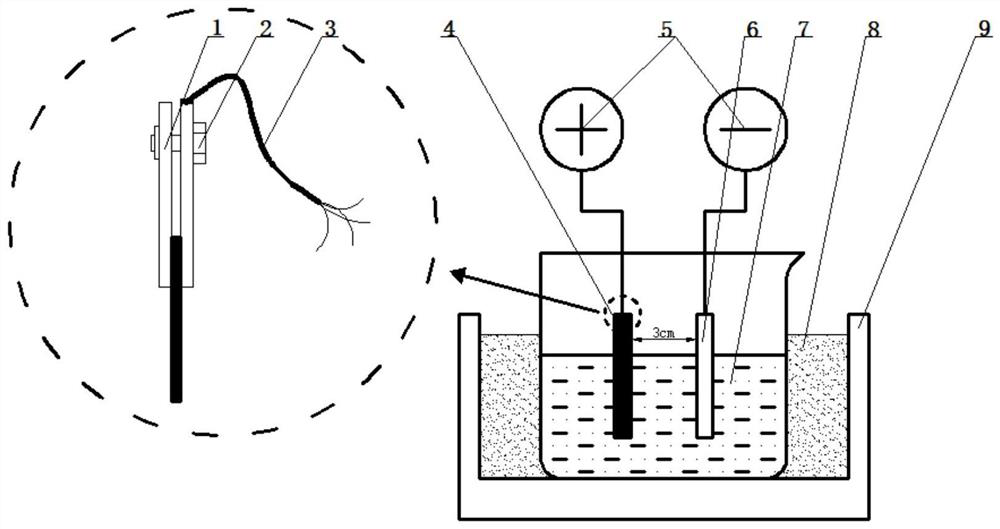

Method used

Image

Examples

Embodiment 1

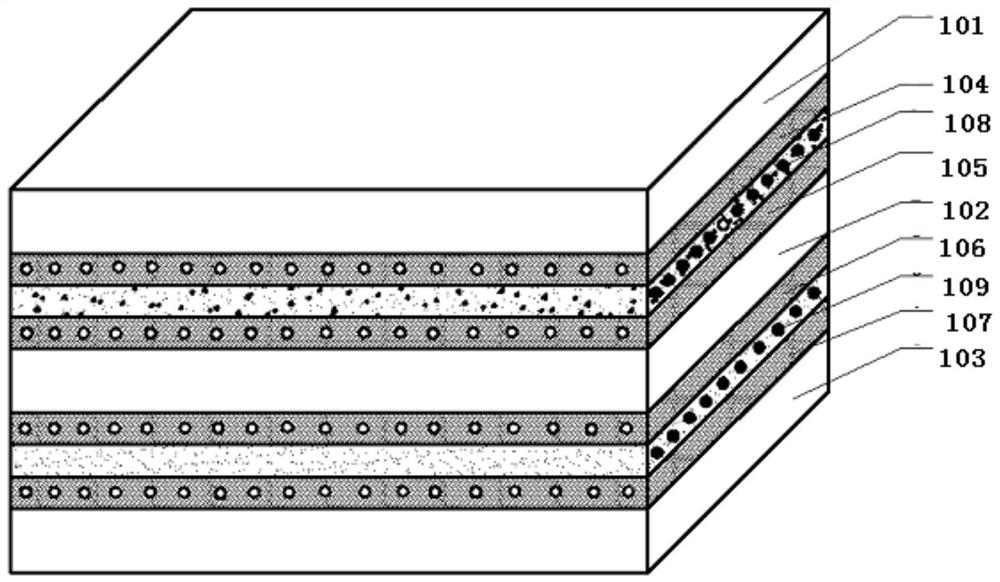

[0044] The steps of preparing polyetheretherketone-based fiber-metal hybrid composites containing modified electric heating layers are as follows:

[0045] (1) Mix the graphene powder into the polyether ether ketone resin powder, the mass fraction of the graphene powder is 1w%, mechanically stir it in advance for 30 minutes and then dry it in an oven for 6 hours to completely remove moisture, then place it in a planetary ball mill at a speed of 300r / min Continue ball milling for 4 hours to mix the powder evenly, sieve out the mixed powder, pack it into bags, and put it in a vacuum drying pot for later use.

[0046] (2) Mix the graphene oxide powder and deionized water to a concentration of 0.5 g / L, and then ultrasonically disperse for 60 minutes to obtain a graphene oxide dispersion, which is sealed and placed in a cool and dry place for later use.

[0047] (3) Evenly coat conductive silver glue with a width of 10mm on both sides of the 100mm edge of the carbon fiber cloth wit...

Embodiment 2

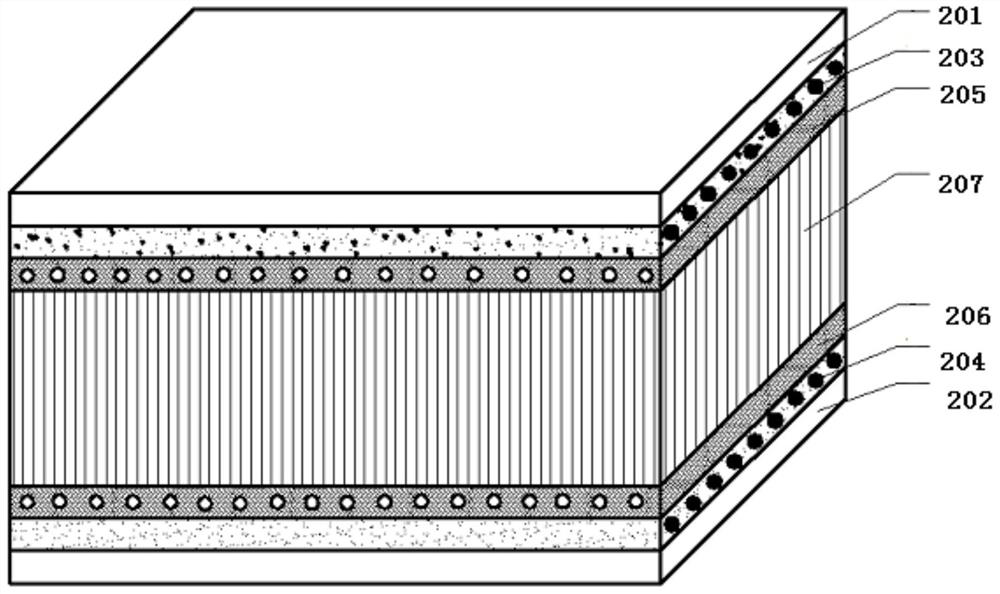

[0052] Prepare the epoxy resin-based aluminum alloy honeycomb sandwich composite material containing the modified electric heating layer, the steps are:

[0053] (1) the epoxy resin of certain quality is dissolved and be dissolved in chloroform solvent with mass fraction 10w%, obtain epoxy resin solution after fully stirring, account for the mass fraction of resin mass by graphene powder be 1w%, graphene powder Add it into the obtained epoxy resin solution, carry out ultrasonic dispersion immediately until the color phase of the dispersion liquid is uniform, and seal it for later use.

[0054] (2) Mix the graphene oxide powder and deionized water to a concentration of 2 g / L, and ultrasonically disperse for 60 minutes to obtain a graphene oxide dispersion, which is sealed and placed in a cool and dry place for later use.

[0055] (3) Evenly coat conductive silver glue with a width of 10mm on both sides of the 100mm edge of the carbon fiber cloth with a size of 110mm×100mm (long...

Embodiment 3

[0060] Prepare the bismaleimide resin-based composite material containing the modified electric heating layer, the steps are:

[0061] (1) Dissolving a certain amount of bismaleimide resin is dissolved in 1,2-dichloroethane solvent solvent with a mass fraction of 10w%, and after fully stirring, a bismaleimide resin solution is obtained, which is taken according to the resin quality Graphene powder with a mass fraction of 1w% was added to the obtained bismaleimide solution, and ultrasonically dispersed immediately until the dispersion was uniform in color, then sealed and ready for use.

[0062] (2) Mix the graphene oxide powder and deionized water to a concentration of 2 g / L, and perform an ultrasonic dispersion treatment for 60 minutes to obtain a graphene oxide dispersion, which is sealed and placed in a cool and dry place for later use.

[0063] (3) Evenly coat conductive silver glue with a width of 10mm on both sides of the 100mm edge of the carbon fiber cloth with a size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com