Preparation method of special alumina for high-purity lithium battery separation membranes

A lithium battery separator and battery separator technology, which is applied to lithium batteries, chemical instruments and methods, battery pack components, etc. The problem of high cost of elution of sodium, to achieve the effect of controllable crystal microscopic morphology, ideal phase composition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

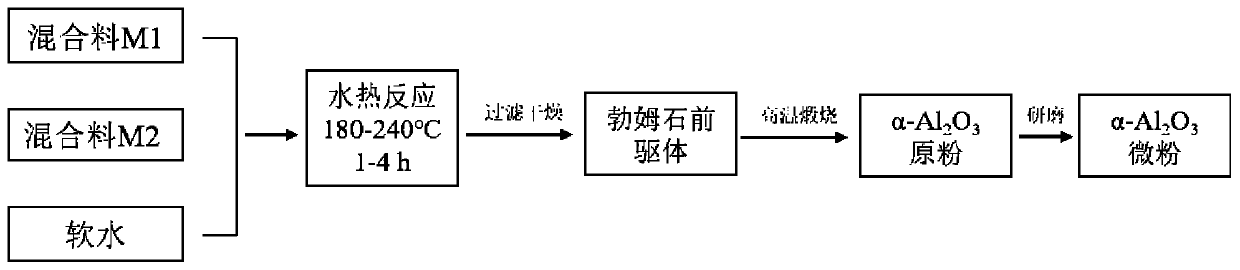

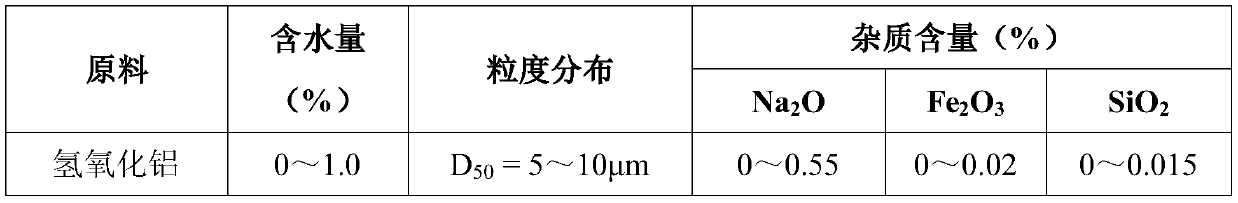

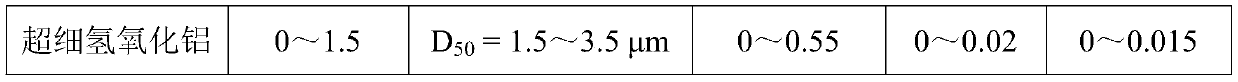

[0039] A kind of preparation method of aluminum oxide for lithium battery diaphragm (flow chart is as figure 1 ), the steps are as follows: aluminum hydroxide material (D 50 = 8.1 μm, Na 2 O=0.37%, Fe 2 o 3 = 0.012%, SiO 2 =0.008%, water content 0.40%) and superfine aluminum hydroxide seed crystal (D 50 = 2.5 μm, Na 2 O=0.39%, Fe 2 o 3 =0.011%, SiO 2 =0.0082%, water content 0.45%) according to the mass ratio of 8:1 mixed to obtain the mixture M1, the mixture M1 and ammonia (ammonia nitrogen content is 26%) according to the mass ratio of 100:1 mixed to obtain the mixture M2, add Soft water to adjust the solid content to 220g / L; set the reaction temperature of the reactor to 220°C, and the holding time to 2h. After the hydrothermal reaction, filter and dry to obtain boehmite; put the boehmite into a high-temperature furnace, Calcined at 1200°C for 3 hours, then high-efficiency grinding and spray drying in a horizontal sander to obtain powder, that is, α-Al 2 o 3 Ultra...

Embodiment 2

[0042] A kind of preparation method of alumina for lithium battery separator, the steps are as follows: aluminum hydroxide (D 50 = 8.1 μm, Na 2 O=0.37%, Fe 2 o 3 = 0.012%, SiO 2 =0.008%, water content 0.40%) and superfine aluminum hydroxide seed crystal (D 50 = 2 μm, Na 2 O=0.39%, Fe 2 o 3 =0.011%, SiO 2 =0.0082%, water content 0.45%) according to the mass ratio of 8:2 mixed to obtain the mixture M1, then, M1 and ammonia water (ammonia nitrogen content is 26%) according to the mass ratio of 100:2 to obtain the mixture M2, Add soft water to adjust the solid content to 240g / L; set the reaction temperature of the reactor to 220°C, and the holding time to 2h. After the hydrothermal reaction is completed, filter and dry to obtain boehmite; put the boehmite into a high-temperature furnace, Calcined at a high temperature of 1200°C for 3 hours, and then efficiently ground through a jet mill to obtain α-Al 2 o 3 Ultrafine powder. The parameters of the jet mill are: the batch...

Embodiment 3

[0045] A kind of preparation method of alumina for lithium battery separator, the steps are as follows: aluminum hydroxide (D 50 = 8.1 μm, Na 2 O=0.37%, Fe 2 o 3 = 0.012%, SiO 2 =0.008%, water content 0.40%) and superfine aluminum hydroxide seed crystal (D 50 = 2 μm, Na 2 O=0.39%, Fe 2 o 3 =0.011%, SiO 2 =0.0082%, water content 0.45%) according to the mass ratio of 8:3 mixed to obtain the mixture M1, then, M1 and ammonia (ammonia nitrogen content is 26%) according to the mass ratio of 100:2 mixed to obtain the mixture M2, add Soft water adjusts the solid content to 250g / L, sets the reaction temperature of the reactor to 210°C, and the holding time to 1.5h. After the hydrothermal reaction is completed, filter and dry to obtain boehmite; put the boehmite into a high-temperature furnace, Calcined at a high temperature of 1100°C for 3 hours, and then efficiently ground through a jet mill to obtain α-Al 2 o 3 Ultrafine powder. The parameters of the jet mill are: the batc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com