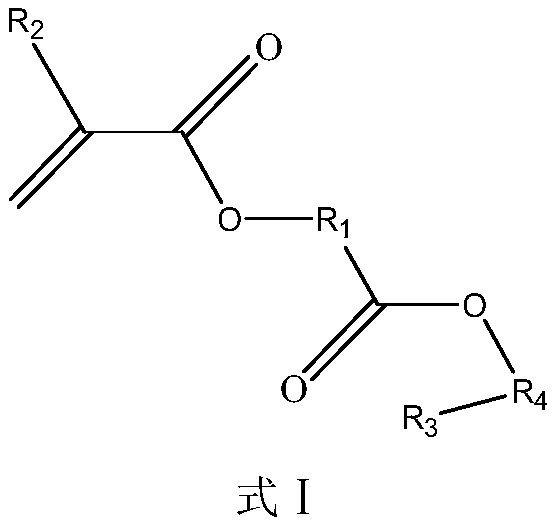

Diester acid protection structure monomer and preparation method thereof

A technology of protective structure and diester acid, which is applied in the field of optical materials, can solve the problems of molecular weight affecting photoresist viscosity, high film hardness, poor adhesion and film formation, etc., to improve the efficiency of deprotection reaction, high yield and purity , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of the diester acid protection structure monomer, comprising the steps of:

[0034] S1: Mix haloalkane, cyclic ketone, and reaction solvent to obtain preparatory solution I; under protective gas, take lithium pellets and add them to the reaction solvent to obtain preparatory solution II;

[0035] S2: Add the preparatory solution I mentioned in S1 dropwise to the preparatory solution II, and the reaction temperature is 30-60° C. to obtain the reaction solution I;

[0036] S3: Pour the reaction solution I described in S2 into the acid, and obtain an alkyl-containing ring alcohol intermediate through stirring, separation, and distillation;

[0037] S4: adding acrylic acid monomers and lactic acid monomers into the reaction solvent, and distilling after reaction to obtain acrylic acid lactic acid esters;

[0038] S5: under a protective gas, mix the alkyl-containing cyclic alcohol intermediate described in S3 with the acrylic lact...

Embodiment 1

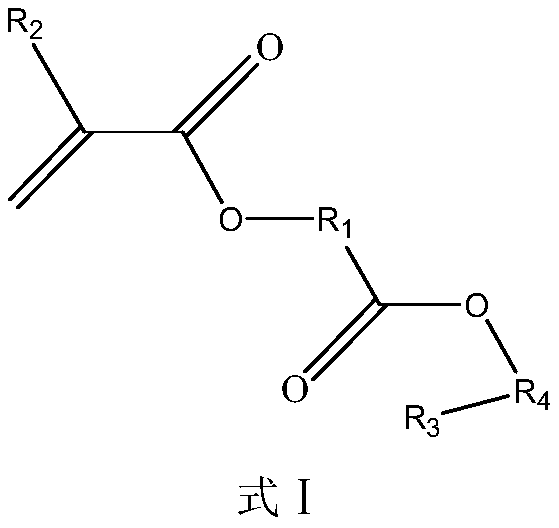

[0077] Embodiment 1 provides a kind of diester acid protection structure monomer, its chemical structural formula is as shown in formula II:

[0078]

[0079] The preparation of the diester acid protection structure monomer comprises the following steps:

[0080] S1: Weigh 100g of cyclopentanone and 253.5g of methyl iodide into 500g of tetrahydrofuran, mix to obtain the preparatory solution I, put it in a constant pressure dropping funnel, and the internal temperature is 20°C; weigh 19.2g of lithium particles, 50g of tetrahydrofuran in Put it in a 2L three-neck flask and protect it with dry nitrogen to obtain the preparation solution II.

[0081] S2: Add 5mL of preparatory solution Ⅰ to preparatory solution Ⅱ to trigger the reaction, release a lot of heat, the internal temperature of the solution rises to 60°C, the solution turns gray and a lot of white smoke comes out, when the internal temperature drops to 40°C, turn on Stir, and continue to add the preparatory solution ...

Embodiment 2

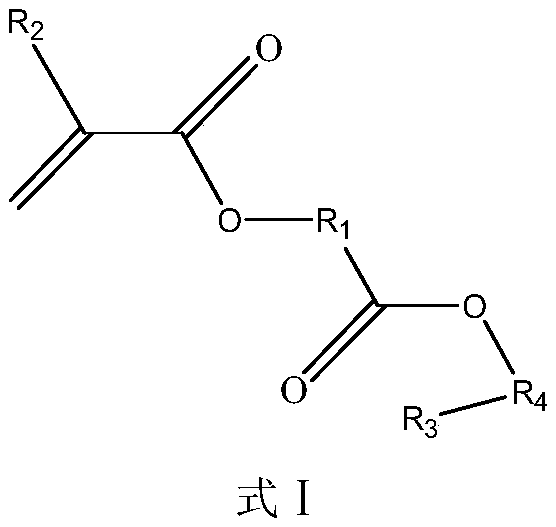

[0087] Embodiment 2 provides a kind of diester acid protection structure monomer, its chemical structural formula is shown in formula III:

[0088]

[0089] The preparation of the diester acid protection structure monomer comprises the following steps:

[0090] S1: Weigh 100g of cyclopentanone and 278.6g of iodoethane into 500g of tetrahydrofuran, mix to obtain the preparatory solution I, put it in a constant pressure dropping funnel, and the internal temperature is 20°C; weigh 19.2g of lithium particles, 50g of tetrahydrofuran Put it in a 2L three-neck flask and protect it with dry nitrogen to obtain the preparatory solution II.

[0091]S2: Add 5mL of preparatory solution Ⅰ to preparatory solution Ⅱ to trigger the reaction, release a lot of heat, the internal temperature of the solution rises to 60°C, the solution turns gray and a lot of white smoke comes out, when the internal temperature drops to 40°C, turn on Stir, and continue to add the preparatory solution I dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com