A kind of extraction method of collagen in bovine bone

An extraction method and collagen technology, which is applied in the field of collagen extraction from bovine bone, can solve the problems of affecting the color and transparency of collagen, reducing the activity of pepsin, and the low yield of hot water extraction, so as to reduce the adverse effects, Uniform distribution of structure, effect of inhibiting Maillard reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

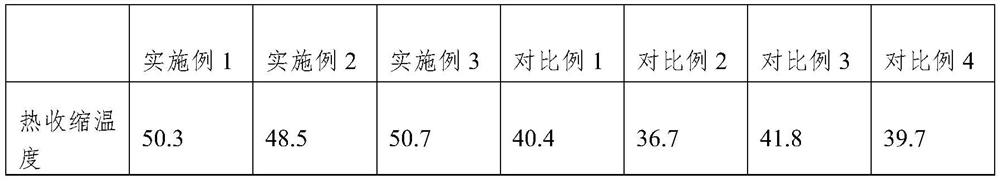

Examples

Embodiment 1

[0032] A method for extracting collagen in bovine bone, comprising the steps of:

[0033] S1 crushing: wash the fresh bovine bone and crush it to pass through a 50-mesh sieve to obtain bovine bone powder;

[0034] S2 quick-freezing: freeze the bovine bone meal at minus 10°C for 1-3 hours;

[0035] S3 thawing: the bovine bone powder is placed in a container, sprayed with steam containing tartaric acid for 10 minutes; the mass fraction of tartaric acid in the steam containing tartaric acid is 30%; the spray rate per 100g of bovine bone powder is 500mL / s ;

[0036] S4 degreasing and decalcification: put the bovine bone powder in the compound enzyme solution at a mass ratio of 1:2 to the material to liquid, and ferment and cultivate it on a shaker at 20°C and 100 rpm for 5 hours, then add the bovine bone powder to the solid to liquid ratio Put it in the Lactobacillus rhamnosus liquid at a mass ratio of 1:1.8, ferment and culture it on a shaking table under the same conditions fo...

Embodiment 2

[0051] A method for extracting collagen in bovine bone, comprising the steps of:

[0052] S1 crushing: Wash the fresh bovine bone and crush it to pass through an 80-mesh sieve to obtain bovine bone powder;

[0053] S2 quick-freezing: freeze the bovine bone meal at minus 30°C for 1-3 hours;

[0054] S3 thawing: the bovine bone powder is placed in the container, sprayed with steam containing tartaric acid for 15 minutes; the mass fraction of tartaric acid in the steam containing tartaric acid is 40%; the spray rate per 100g of bovine bone powder is 700mL / s ;

[0055] S4 degreasing and decalcification: Put the bovine bone powder in the compound enzyme solution at a mass ratio of 1:5 to the material and liquid, and ferment and cultivate it on a shaking table at 35°C and 200 rpm for 10 hours, then add the bovine bone powder to the solid to liquid ratio Put it in the Lactobacillus rhamnosus liquid at a mass ratio of 1:3.6, ferment and culture it on a shaking table under the same c...

Embodiment 3

[0070] A method for extracting collagen in bovine bone, comprising the steps of:

[0071] S1 crushing: wash the fresh bovine bone and crush it to pass through a 60-mesh sieve to obtain bovine bone powder;

[0072] S2 quick-freezing: freeze the bovine bone meal at minus 20°C for 1-3 hours;

[0073] S3 thawing: the bovine bone powder is placed in the container, sprayed with tartaric acid-containing water vapor for 12 minutes; the mass fraction of tartaric acid in the tartaric acid-containing water vapor is 35%; the spray rate per 100g of bovine bone powder is 600mL / s ;

[0074] S4 degreasing and decalcification: Put the bovine bone powder in the compound enzyme solution at a mass ratio of 1:3 to the material and liquid, and ferment and cultivate it on a shaking table at 25°C and 150 rpm for 7 hours, then add the bovine bone powder according to the material to liquid ratio Put it in the Lactobacillus rhamnosus liquid at a mass ratio of 1:2, ferment and culture on a shaking tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com